18

ENGINE

161

18.4.13

Checking

crankshaft

run-out

at

bearing

pin

18.4.14

Cylinder.

Nlkasli

CiD

coating

304609-10

18.4.15

Checkinlfmeasurinll

the

cylinder

304689-10

30469&-10

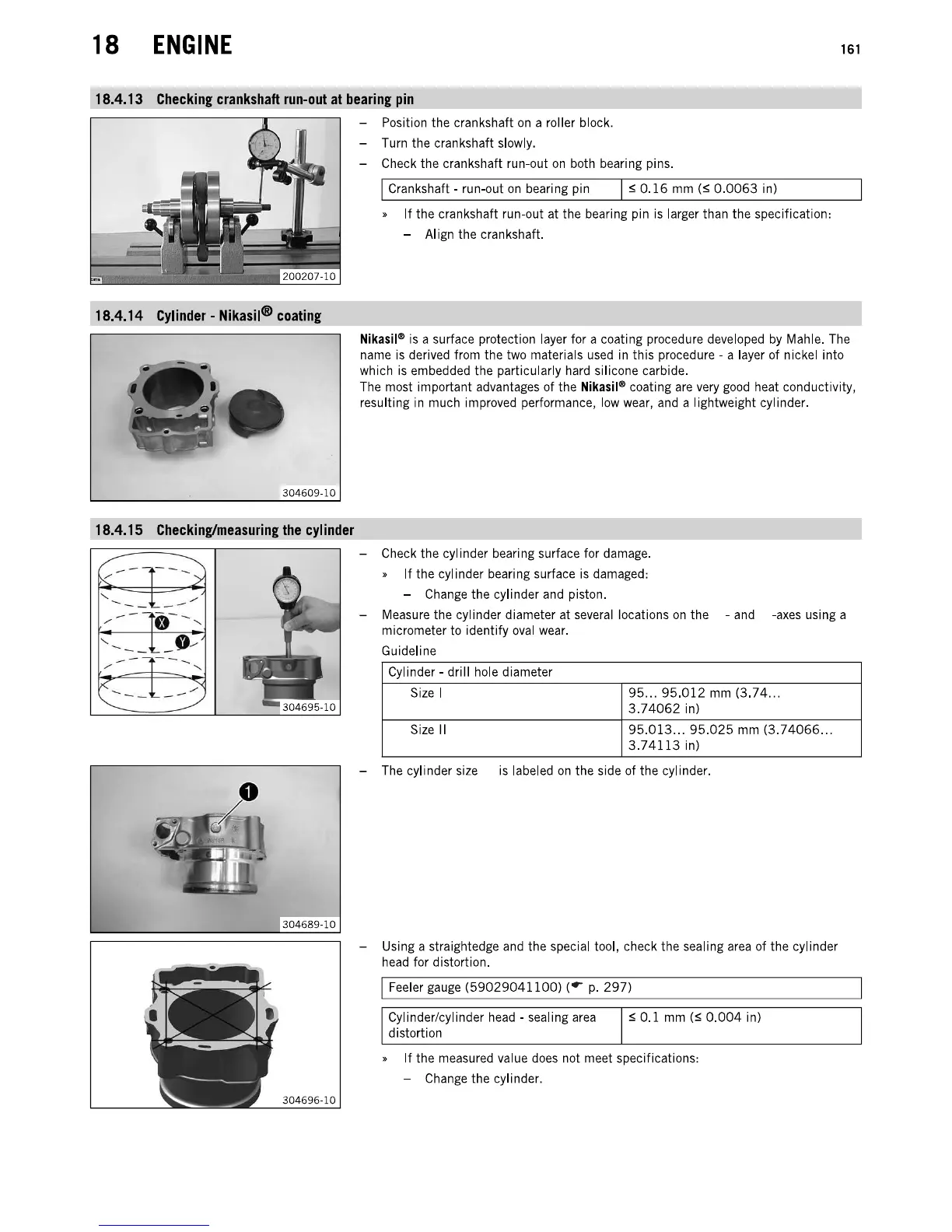

- Position the crankshaft

on

a roller block.

- Turn the crankshaft slowly.

- Check the crankshaft run·out

on

both bearing pins.

I Crankshaft· run·out

on

bearing pin I

,;

0.16

mm

(,;

0.0063

in)

•

If

the crankshaft run·out at the bearing pin is larger than the specification,

- Align the crankshaft.

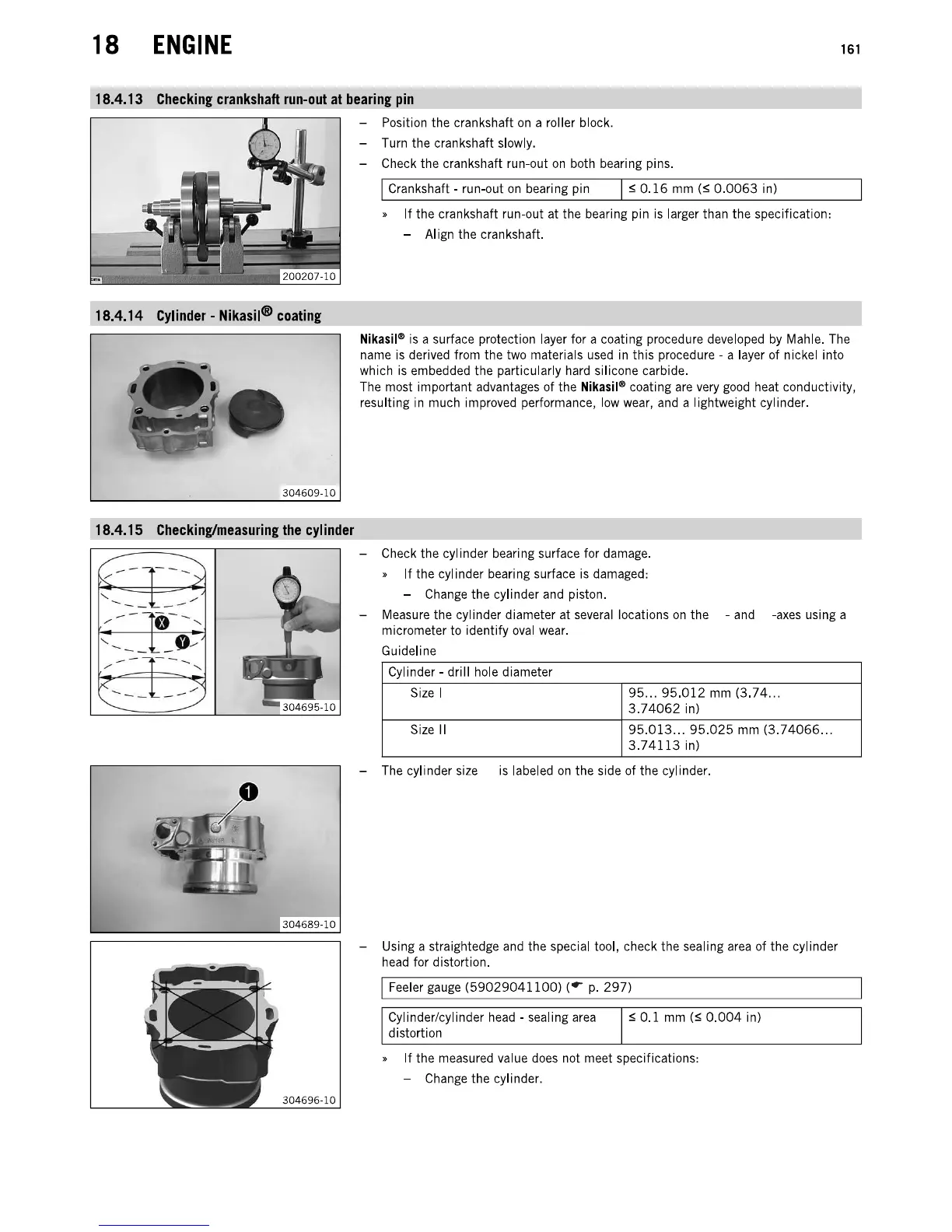

Nikasil

e

is a surface protection layer for a coating procedure developed by Mahle. The

name is derived from the two materials

used

in this procedure· a layer of nickel into

which is embedded the particularly hard silicone carbide.

The most important advantages of the

Nikasil

e

coating

are

very

good

heat conductivity,

resulting in much improved performance, low

wear,

and a lightweight cylinder.

- Check the cylinder bearing surface for damage.

•

If

the cylinder bearing surface is damaged,

- Change the cylinder and piston.

Measure the cylinder diameter at several locations

on

the - and ·axes using a

micrometer to identify oval wear.

Guideline

Cylinder·

drill hole diameter

Size I

95

...

95.012

mm

(3.74

...

3.74062

in)

Size II

95.013

...

95.025

mm

(3.74066

...

3.74113

in)

- The cylinder size is labeled

on

the side

of

the cylinder.

- Using a straightedge and the special tool, check the sealing area of the cylinder

head

for distortion.

I Feeler gauge

(59029041100)

(

..

p.

297)

Cylinder/cylinder

head·

sealing

area

distortion

,; 0.1

mm

(,;

0.004

in)

•

If

the measured value does not meet specifications,

- Change the cylinder.

Loading...

Loading...