Maintenance

110

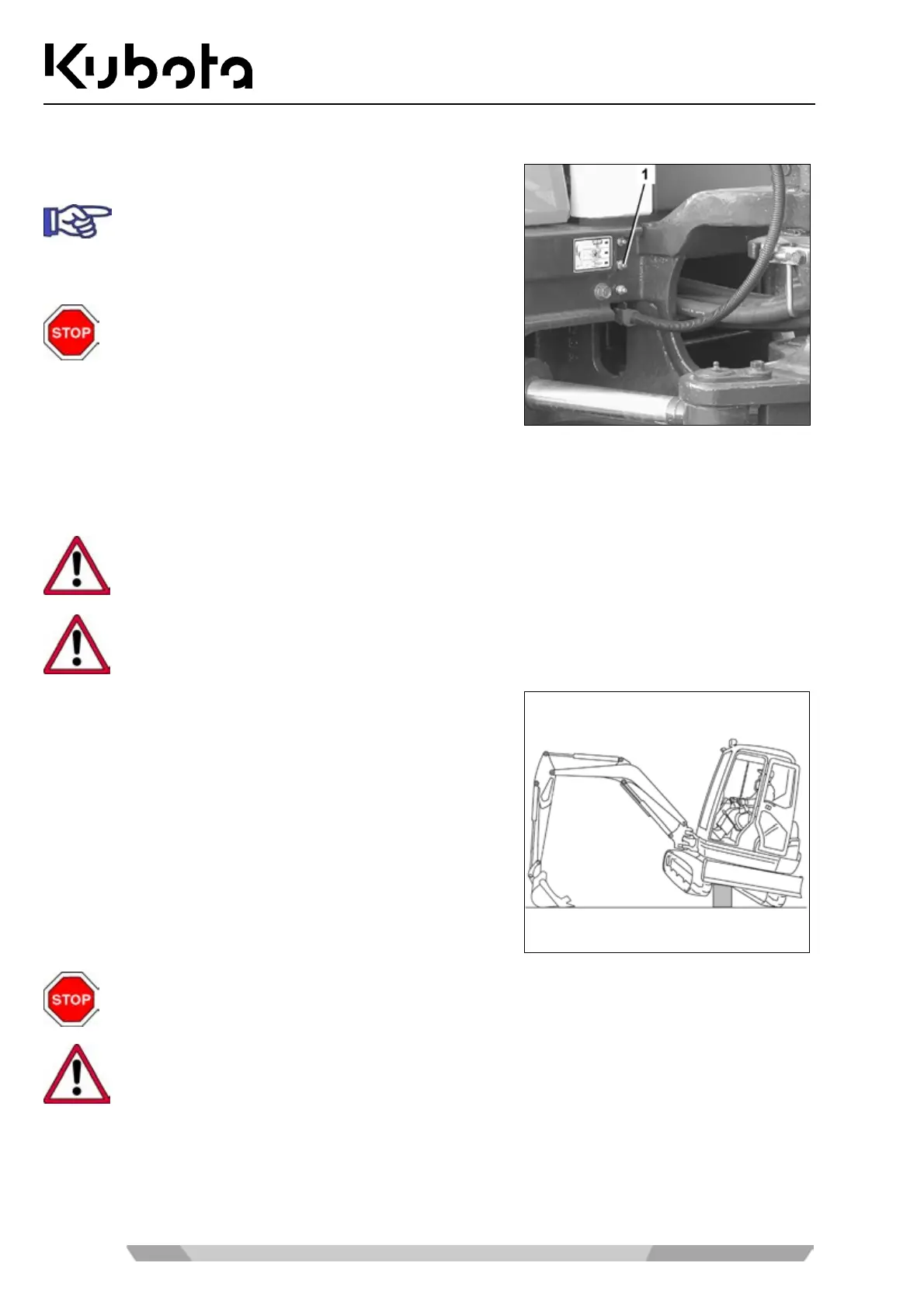

Greasing the pitch bearing

• Fill grease through the grease nipple (1) with a grease gun.

Grease at each 90

position of the pitch bearing.

Using the grease gun, apply 5 shots at every posi-

tion. See the "Recommended lubricants" section

(page 116).

When moving the swivel frame, make sure no

person or material is in the swivel area. Turn the

starter switch to the STOP position and remove the

key before the next greasing procedure.

• Operate the excavator and swivel the swivel frame by 90°

several times. After greasing, swivel the swivel frame 360°

several times to distribute the grease evenly.

Checking and tensioning the crawler tension

If the crawlers are too tight, wear is increased.

If the crawlers are too loose, wear is increased and the crawlers may come off.

When parking an excavator with rubber crawlers, ensure that the

seam (∞) is on top half way between the two sliders (see fig-

ure/1, "Checking the crawler tension", page 111).

• Clean all parts of the running gear, paying particular atten-

tion to stones between the crawler and sprocket or idler.

Clean the area of the crawler tensioning cylinder.

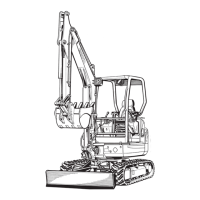

• Swivel the swivel frame 90° to the direction of travel as

shown in the figure.

• Lower the front attachments on the ground and raise the

excavator about 200 mm off the ground on one side.

Have a guide supervise the procedure.

Support the excavator with appropriate backing material, observing the vehicle weight.