1-S67

M5040, M6040, M7040, WSM

ENGINE

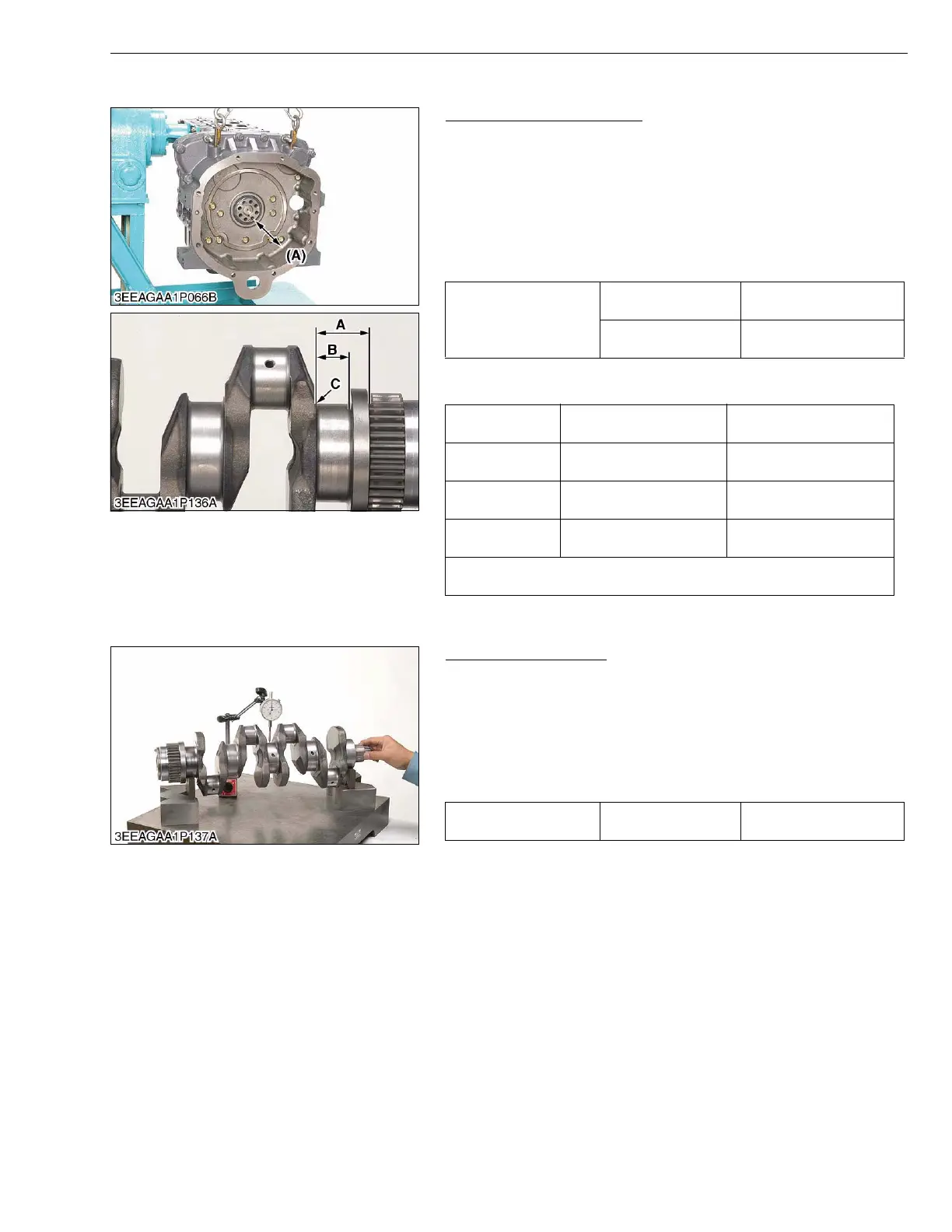

(4) Crankshaft

Crankshaft Side Clearance

1. Set a dial indicator with its tip on the end of the crankshaft.

2. Measure the side clearance by moving the crankshaft to the front

and rear.

3. If the measurement exceeds the allowable limit, replace the

thrust bearings.

4. If the same size bearing is out of specifications because of the

crankshaft journal wear, replace it with an oversize one referring

to the table and figure.

(Reference)

• Oversize dimensions of crankshaft journal.

W1066738

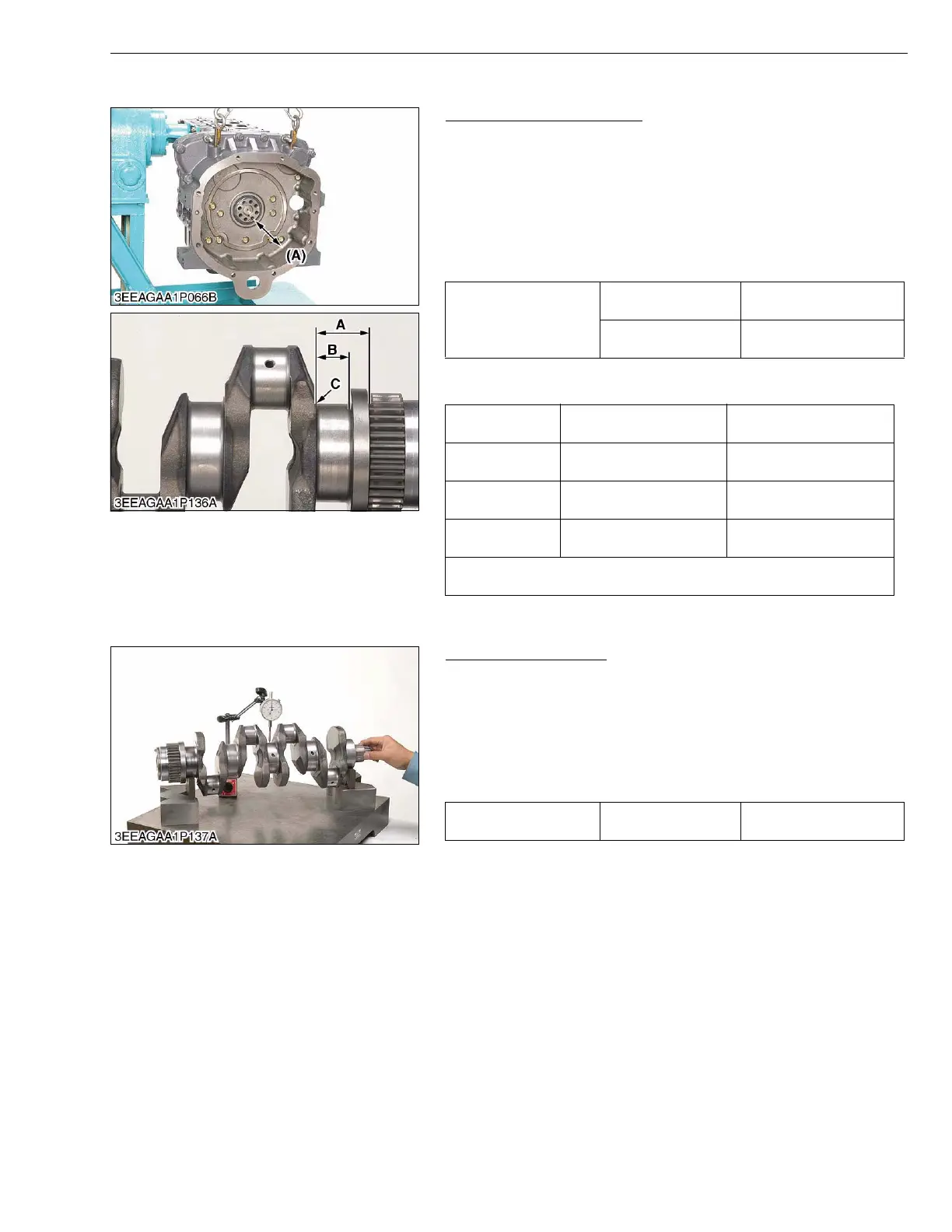

Crankshaft Alignment

1. Support the crankshaft with V block on the surface plate and set

a dial indicator with its tip on the intermediate journal at right

angle.

2. Rotate the crankshaft on the V block and get the misalignment

(half of the measurement value).

3. If the misalignment exceeds the allowable limit, replace the

crankshaft.

W1067285

Side clearance of

crankshaft

Factory spec.

0.15 to 0.35 mm

0.0059 to 0.0138 in.

Allowable limit

0.50 mm

0.0197 in.

Oversize

0.2 mm

0.008 in.

0.4 mm

0.016 in.

Dimension A

41.1 to 42.1 mm

1.6181 to 1.6575 in.

41.2 to 42.2 mm

1.6220 to 1.6614 in.

Dimension B

28.20 to 28.25 mm

1.1102 to 1.1122 in.

28.40 to 28.45 mm

1.1181 to 1.1201 in.

Dimension C

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

(0.8S)

The crankshaft journal must be fine-finished to higher than ∇∇∇∇.

(A) Side Clearance of Crankshaft

Crankshaft alignment Allowable limit

0.02 mm

0.00079 in.

Loading...

Loading...