Level Best Service Guide Page 16

SEGMENT

5

Solenoid Valves

B Sticking Valve

1. A leg will not operate or will only go in one direction. Check the

reservoir fluid level, refer to Segement 1: Erractic Leg Operation; A.

Low Fluid.

2. Check leg valve operation.

a. Check that the valve coil is receiving a ground signal from the control

module. If no signal is present at the valve coil refer to Segment 6:

Control Touchpad (Figure 5a.)

b. Remove valve from manifold; use caution as fluid in the manifold

may be under pressure. Test valve actuation on the workbench using a

12-volt battery or a regulated 12-volt power supply.

i. Check for bent valve assembly.

ii. Check the valve orifices for any obstructions or contaminates.

c. Replace valve.

3. All legs move only in one direction.

a. Check that 4-way valve coil is receiving ground signal from the

control module. If no signal is present at the valve coil refer to Segment

6: Control Touchpad (Figure 5a.)

b. Remove 4-way valve from manifold; use caution as fluid in the

manifold may be under pressure. Test valve actuation on the workbench

using a battery or a regulated 12-volt power supply.

i. Check for bent valve assembly.

ii. Check the valve orifices for any obstructions or contaminates.

c. Replace valve.

CAUTION should be

exercised when

testing any of the

motor control wires. Use

only a quality volt/ohm

meter. Do not ground or

spark wires. This will

permanently damage the

motor control module.

A Functions

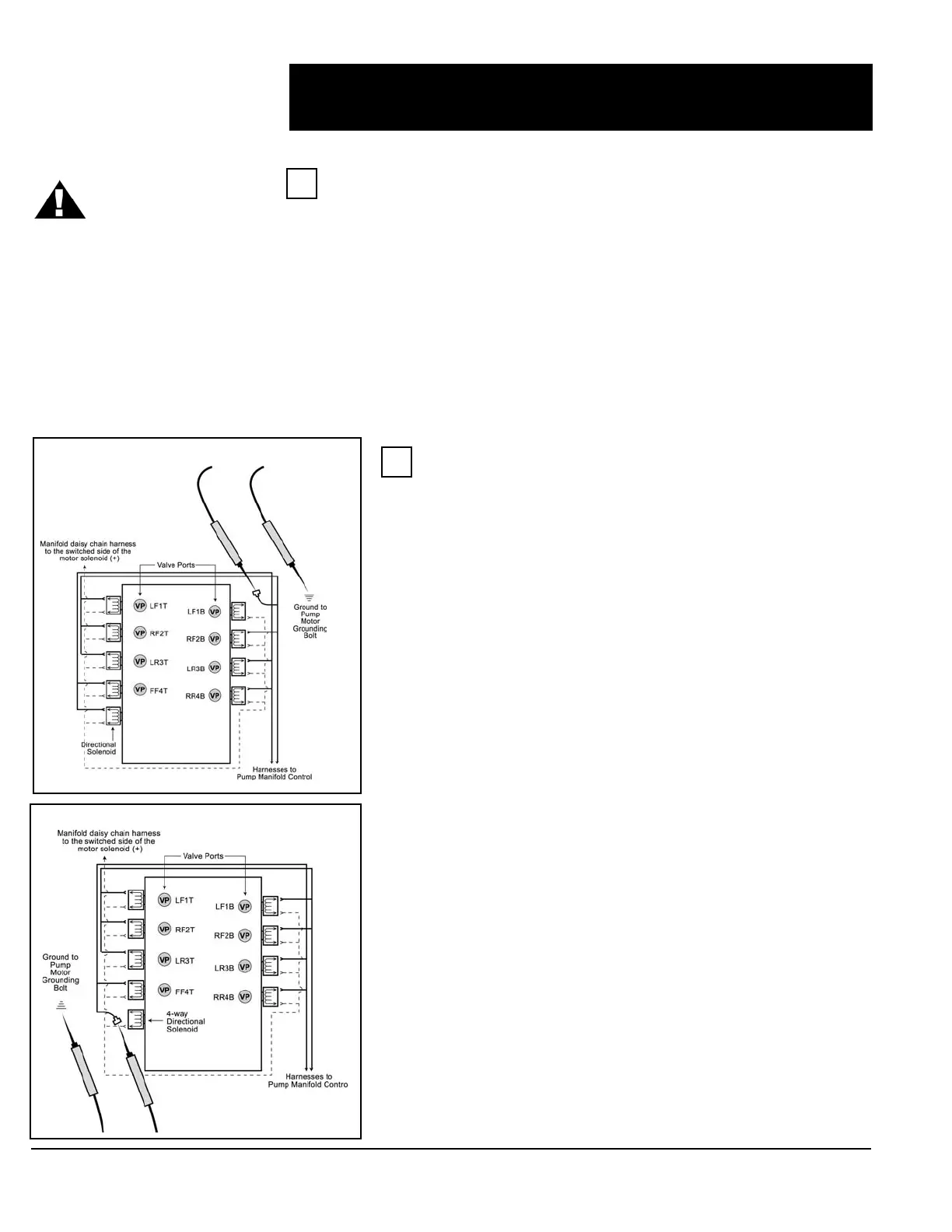

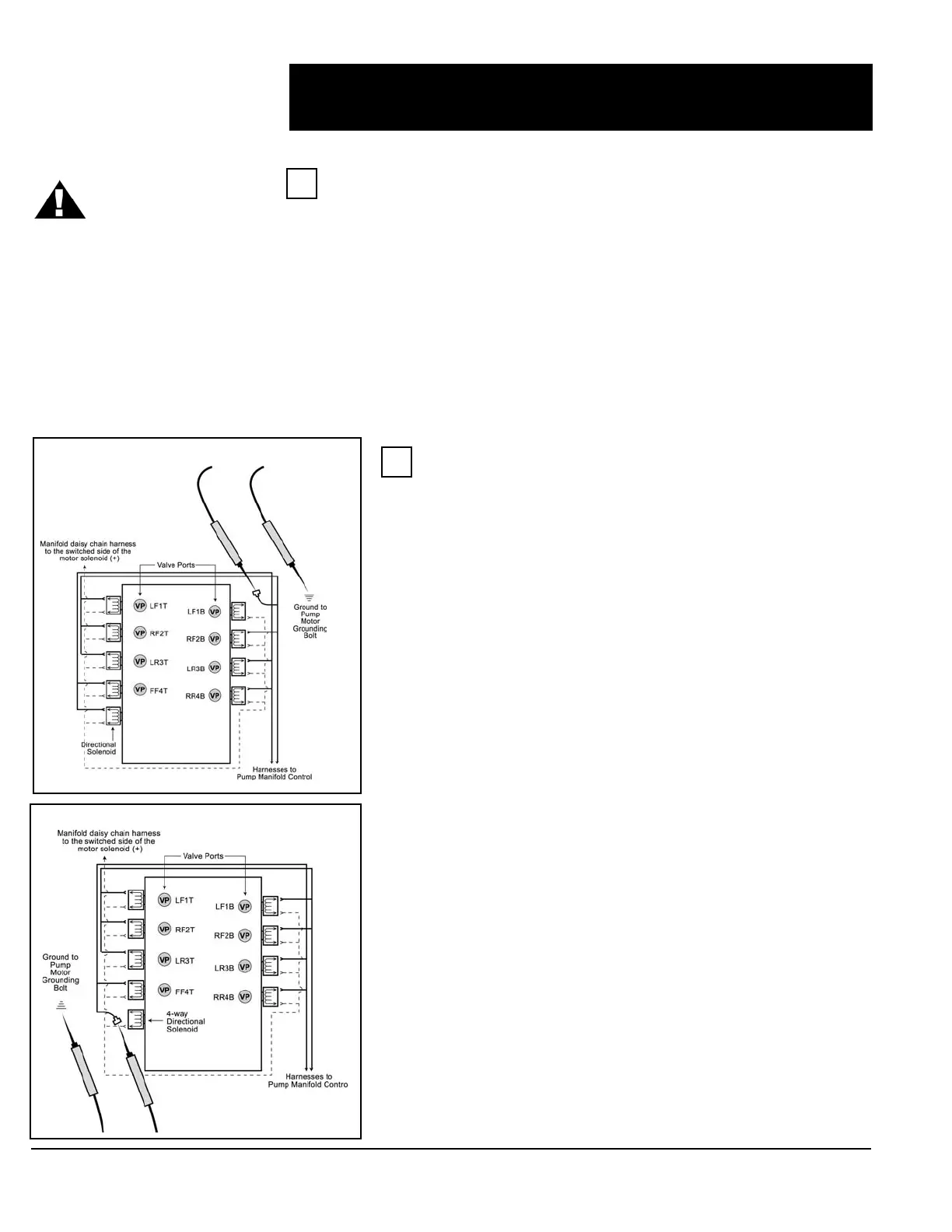

The solenoid valves control the operation of the leveling systems cylinders and legs.

There are eight cylinder / leg valves and one directional valve (4-way). The leg valves

allow for the operation of the individual legs while the 4-way controls the direction of all

the legs.

1. The four leg valves located at manifold ports “1B” through “4B” open as required to

allow the return of fluid during the extend sequence, and ports “1T” through “4T” open

during the retract sequence. The 4-way valve is shifted (energized) only during the

extend cycle.

2. 12-volts should be present on one of the valve coil terminals at each valve coil

during pump motor operation.

Figure 5b

Figure 5a

Loading...

Loading...