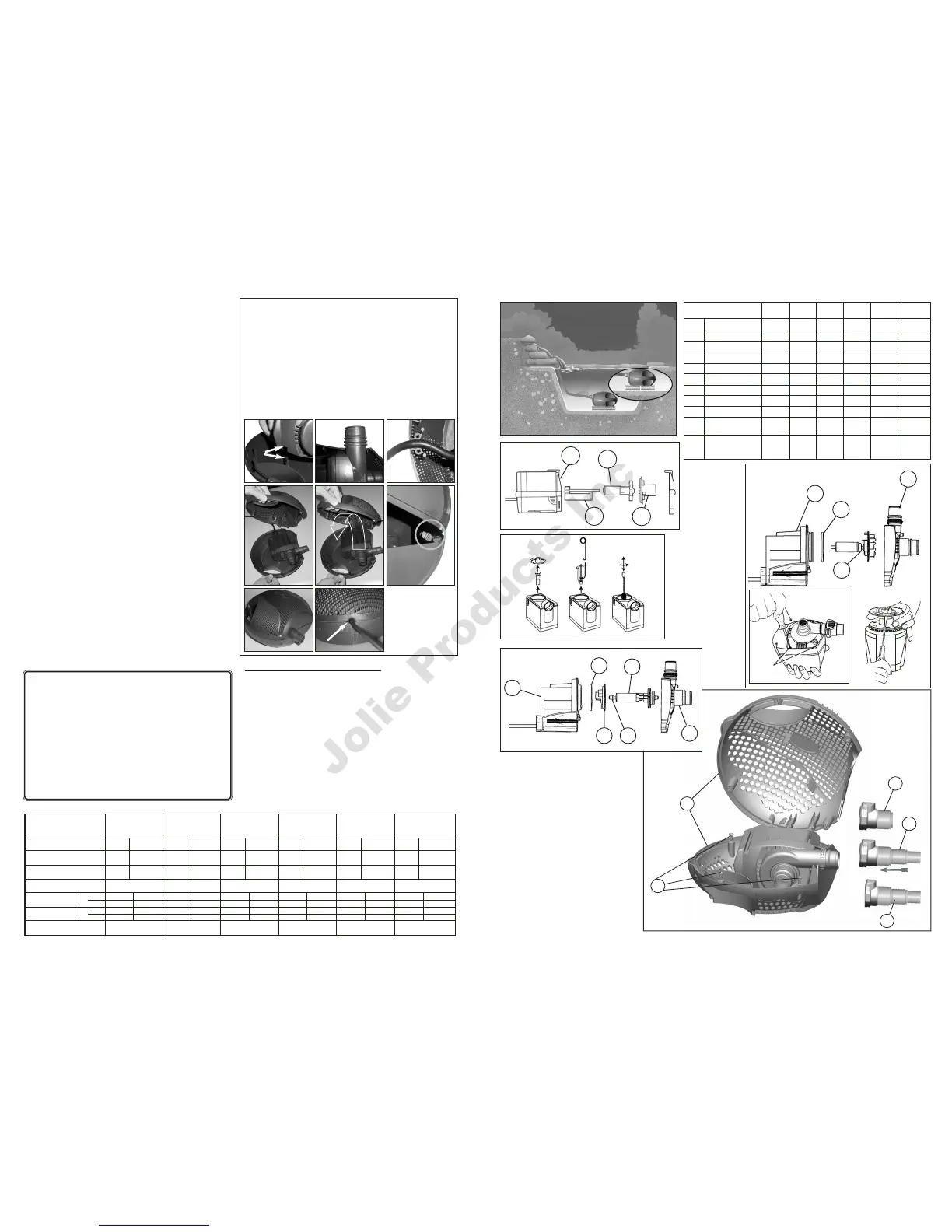

Max-Flo 2000/7500, 2400/9000, and 2900/11000 (Fig. 3)

1) Using a Phillips (cross-headed) screwdriver, unscrew the four

screws on the impeller cover (4) and remove it

2) Using a flathead screwdriver, carefully lift out the impeller

assembly.

3) Clean all components in clean water only, using a small, non-

abrasive brush, if necessary. DO NOT USE DETERGENTS OR

OTHER CHEMICAL CLEANERS which could damage the pump

and pollute the pond

4) Reassemble all components with care (see

Closing the Pump

Cage

), ensuring that the impeller bearing, bushing and O-Ring

are correctly placed at the bottom of the impeller well.

Replacing the Bushing and O-Ring

(Replacement pack not included. Part # PT-466).

For Max-Flo

1500/6000,

2000/7500, 2400/9000 and

2900/11000 only

Though the bushing is made of very resistant material, it is prone to

wearing in certain conditions. For this reason, it is recommended

that you replace it whenever the impeller unit is replaced. Follow the

instructions provided with the replacement parts package. Once you

have replaced the Bushing and O-Ring, reassemble all parts with

care (see Fig. 3 &

Closing the Pump Cage

).

Volts 120 230-240 120 230-240 120 230-240 120 230-240 120 230-240 120 230-240

Hertz 60 50 60 50 60 50 60 50 60 50 60 50

Watts 32 32 65 55 100 80 100 100 100 100 130 125

Maximum depth 6’6”/2 m 6’6”/2 m 6’6”/2 m 6’6”/2 m 6’6”/2 m 6’6”/2 m

Max flow rate

Max head

Degree of protection IPX8 IPX8 IPX8 IPX8 IPX8 IPX8

MAX-FLO PUMP 600/

2200

900/

3500 1500/6000 2000/7500 2400/9000 2900/11000

PT-340 PT-342 PT-344 PT-346 PT-348 PT-350

US GPH

LPH

ft

m

899

3400

6’4”

1.95

977

3700

6’2”

1.9

582

2200

5’10”

1.8

582

2200

5’10”

1.8

11’6”

3.50

1585

6000

13’5”

4.10

1558

5900

12’2”

3.7

1981

7500

12’2”

3.7

1981

7500

12’2”

3.7

2378

9000

12’2”

3.7

2378

9000

14’9”

4.5

2853

10800

14’9”

4.5

2800

10600

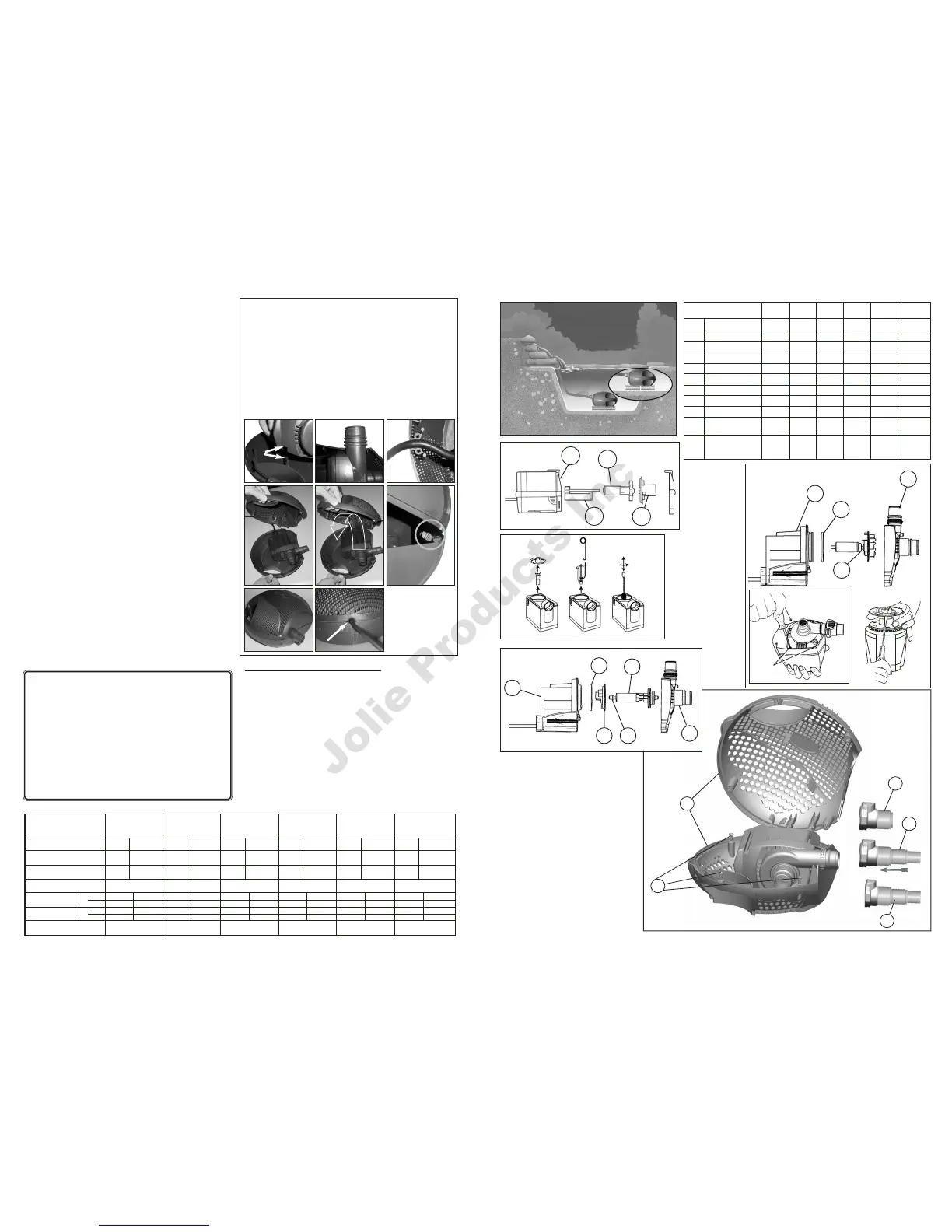

Closing the Pump Cage

Place the pump inside the bottom half of the cage. Ensure that the

electrical cord is properly seated inside the recess located on the

bottom half of the cage.

At a 45° angle, join the top half of the cage to the bottom half of

the cage by first aligning the two posts, located on the top half of

the cage, with the two docking holes, located at the bottom half of

the cage. Close the cage completely, ensuring that both halves are

fully aligned. Lock the pivot pin fasteners as explained in

section called

Opening and Closing the Pump Cage

.

Ensure that the pump cage is securely locked and the electrical cord

is seated properly in position before lifting or operating the pump.

TROUBLESHOOTING

LOW FLOW FROM PUMP

• Check that the pump cage is clean

• Check the hose for blockages

• Check that the pump is free of dirt and debris

NO FLOW FROM PUMP

• Check that the power supply is on

• Check the fuse (UK market only) and wiring

• Check that the plug is correctly connected to the electrical

receptacle/socket

• Check that the pump cage is clean

• Check the hose for blockages

• Check that the pump is free of dirt and debris

• Check that the pump is completely immersed in water

WARRANTY

The Pumps are guaranteed against defects in material or

workmanship for a period of 3 years from date of purchase,

under normal usage. PowerJet Pumps will be repaired or

replaced at manufacturer’s discretion, free of charge. This

warranty does not apply to any PowerJet Pump which has

been subjected to misuse, negligence, tampering or accidental

damage to the impeller or impeller shaft. No liability is

assumed with respect to loss or damage to livestock or

personal property irrespective of the cause thereof. This

warranty does not affect your statutory rights. Failure caused

by misuse is not covered by this warranty.

65

CASCADE

ABC

D

G

H

F

E

600/2200 900/3500 1500/6000 2000/7500 2400/9000 2900/11000

PT-340 PT-342 PT-344 PT-346 PT-348 PT-350

1 Moteur PT-382 PT-384 PT-388 PT-390 PT-392 PT-394

2 Joint d’étanchéité – PT-762 PT-763 PT-764 PT-764 PT-764

3 Couronne PT-455 PT-457 PT-459 PT-461 PT-461 PT-465

3A Arbre de la couronne PT-759 PT-761 – – – –

4 Couvercle de la couronne PT-737 PT-738 PT-733 PT-735 PT-739 PT-739

5

Couvercle du puits de la couronne

– PT-768 – – – –

6 Boîtier de la pompe PT-439 PT-444 PT-445 PT-446 PT-446 PT-446

7 Axes d’articulation PT-447 PT-447 PT-447 PT-447 PT-447 PT-447

8

Raccord auto-bloquant (38 mm)

– – – PT-638 PT-638 PT-638

9 Raccord universel – – – PT-640 PT-640 PT-640

(19, 25, 32 mm)

10

Accouplement rigide universel

PT-636 PT-636 PT-636 – – –

(19, 25, 32 mm avec adapteur pour

raccord auto-bloquant de25 mm

PIÈCES DE RECHANGE

6

7

9

8

10

Fig.4

2

3

4

1500/6000

2000/7500

2400/9000

2900/11000

1

Fig.3

Fig.1

1

3A

3

4

600/2200

900/3500

2

5 3A

3

4

1

Fig.2

Pour retirer l’arbre de la

couronne, utiliser l’outil fourni.

Fig.1A

VIS

VIS

Loading...

Loading...