60

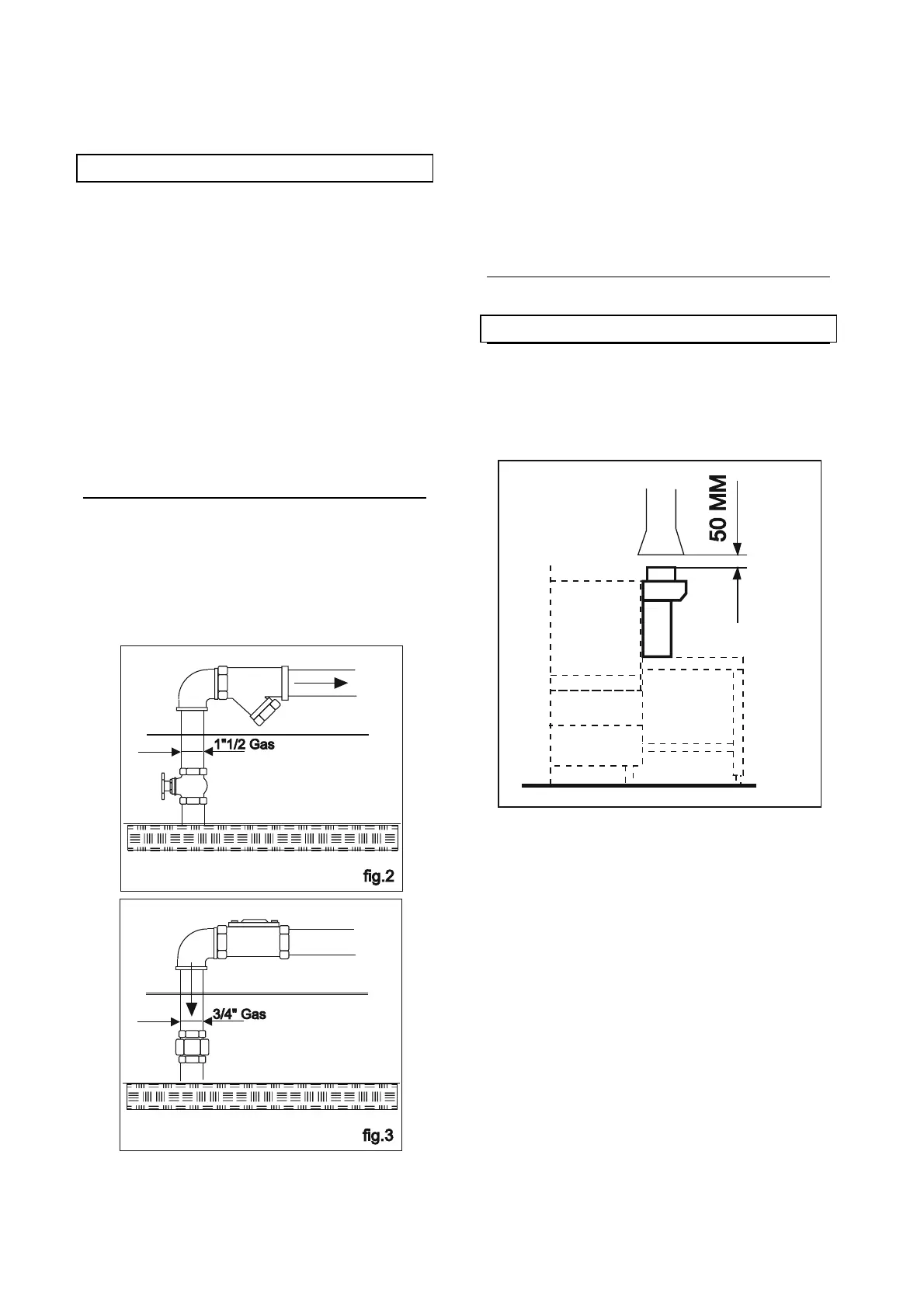

9.6 - STEAM FEEDING *

As far as steam feeding is concerned,

connect to the machine fittings indicated

in the installation drawings. In order to

make the equipment independent from he

general steam distribution network, it is

necessary to use gate and gas on/off

valves (see draw 2 and 3).

.

This type of feeding should be supplied at

a pressure ranging from 1 bar (100°C) to

2 bar (121°C).

The steam used should be absolutely

saturated and dry.

STEAM EXHAUST *

The condensed steam exhaust shall have

an appropriate slope toward the recovery

installation or a blow-by pump, in order to

guarantee an autonomous scavenging of

the condensed steam.

ma ti c-i d rau li c2

matic-idraulic2

N.B.: for possible maintenance operations,

it is advisable to arrange a gate valve

parallel with the discharge so that it is

possible to deviate condensation towards a

runoff pit.

for steam machines only

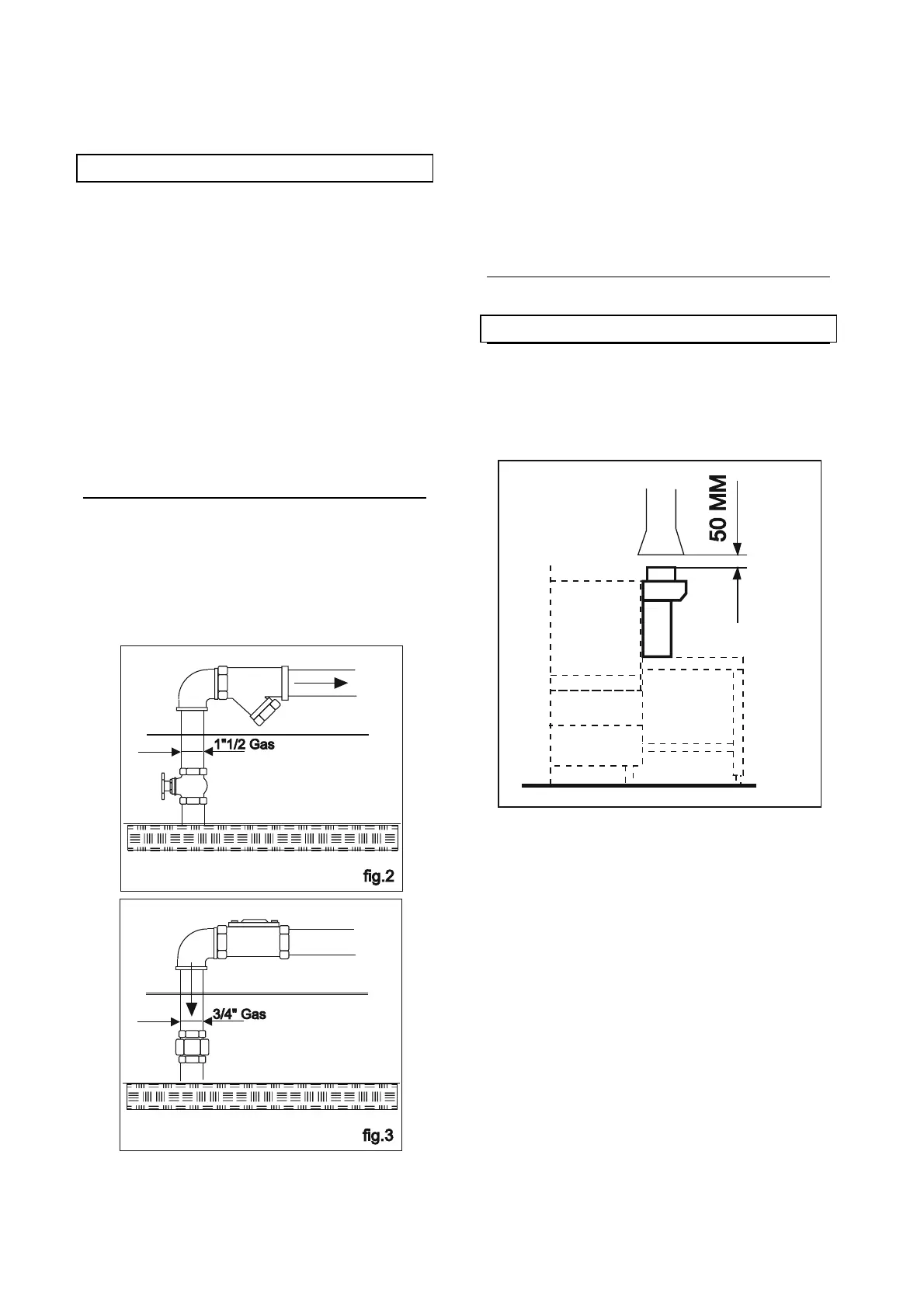

9.7 - VAPOURS SUCTION

For machines equipped with splashguard with

collar or heat recovery, carry out the

necessary connection as showed in THE

figure.

In any case it is necessary to provide a way

to extract steam through a hood or a similar

system.

Loading...

Loading...