LAUNCH 440(440W) 455(455W) Installation Manual

6

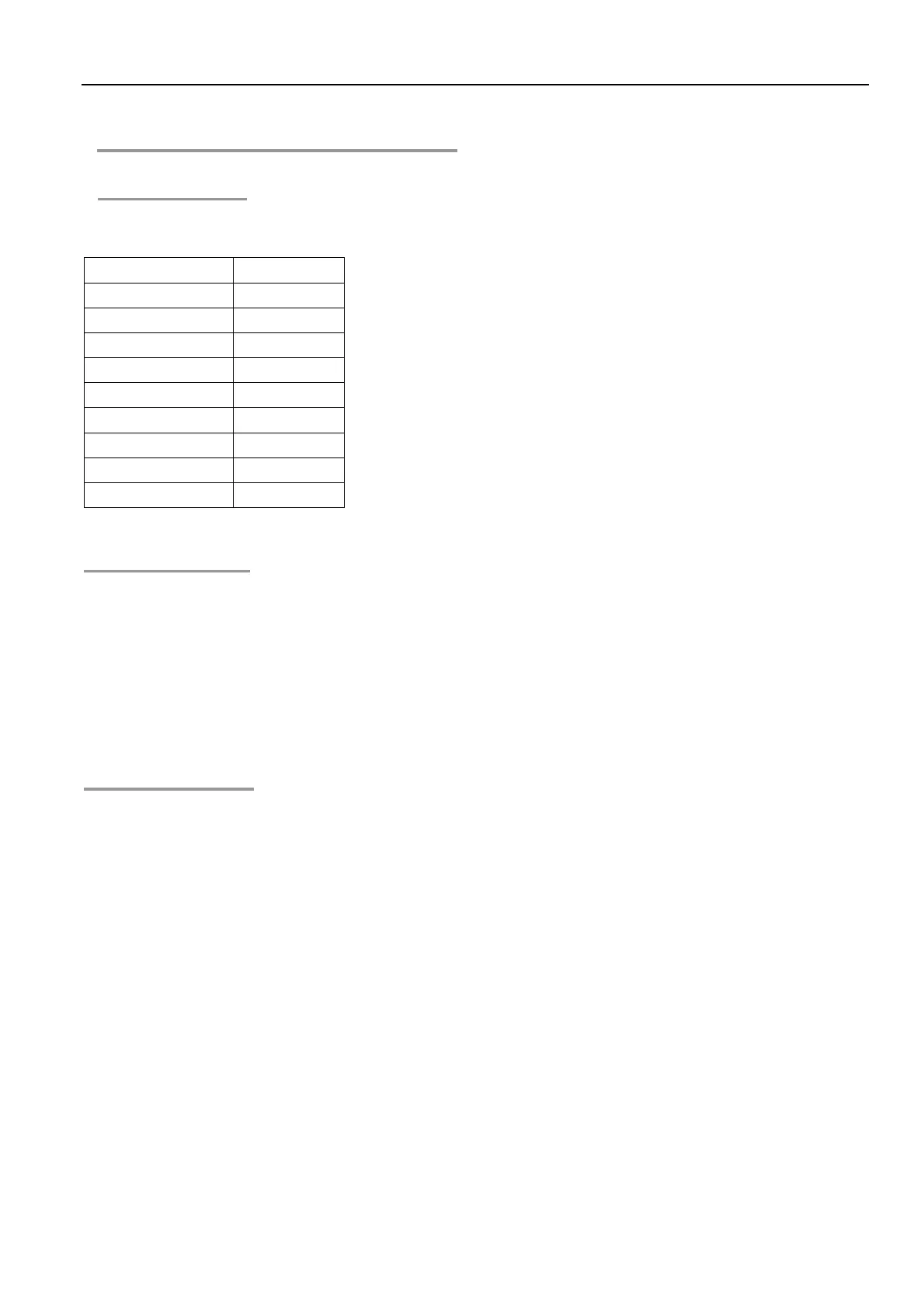

3 Tools for installation and

adjustment

To perform the installation and adjustment, please get the

following tools ready:

Tools Model

Leveling Meter For carpentry

Chalk Min. 4.5m

Hammer 1.5kg

Adjustable Wrench 40mm

Open Spanner Set 11mm-23mm

Ratchet Socket Set

Flat Screw Driver 150mm

Rotary hammer Drill 16mm

Alloy Drill-bit

¢16mm

4 Unpacking

l Unpack and remove the packing materials. Inspect the

lift for possible damage or loss of accessories during

transportation.

l Keep the packing materials out of the reach of children to

avoid accident. Packing materials should be disposed

of in a proper way.。

5 Installation

5.1 Precautions for installation

l The wrong installation will cause the lift damage or

personal injury. The manufacturer will not undertake any

responsibilities for any damage caused due to incorrect

installation and usage of this equipment, whether directly

or indirectly.

l The correct installation location shall be on “horizontal”

floor to ensure the horizontal lifting. The slightly slope

floor can be corrected by proper shimming. Any big slope

will affect the level of the lifting. If the floor is of

questionable slope, consider a visual inspection, or pour

a new horizontal concrete slab if possible. Don’t expect to

compensate for the serious slope by shimming.

l Don’t install the lift on any asphalt surface or any surface

other than concrete. The lift must be installed on concrete

floor conforming to the minimum requirement showed in

this manual. Don’t install the lift on the concrete with

seams or crack and defect. Please check together with

the architect.

l Without the written approval of the architect, don’t install

the lift on a second floor with basement.

l Overhead obstruction: The lift installation area can’t have

any overhead obstruction, such as heater, building

support, electrical pipe, etc.

l Concrete drilling test: The installation personnel can test

the concrete thickness at each site by drilling test. If

several lifts are installed at one place, it is preferred to

make drilling test in each site.

l Power supply: Get ready the power supply before the

installation. All the electric wiring and connecting should

be performed by a certified electrician.

5.2 Installation procedures

5.2.1 Overall Positioning

Selecting installation site based on the following conditions::

l If the thickness of the whole ground concrete is greater

than 200mm, the lift can be installed directly.

l If the thickness of the whole ground concrete is less than

200mm, the concrete slab must be made. The minimum

thickness of the concrete slab is 200mm, with 7 days of

minimum curing time.

l The concrete slab shall have steel bar reinforcement and

must be leveled.

l Check the possible obstruction, e.g. low ceiling, top

pipeline, working area, passage, exit, etc.

l Allow enough space around the lift for accessing the

vehicle. (as in Fig. 5)

www.diagtools.eu, Pernavas 43A, Riga, Latvia, LV-1009, +37129416069, info@diagtools.eu

Loading...

Loading...