- 31 -

4. Cold junction compensation (CJC) errors. Our meters do not use an actual cold

junction in ice water as the thermoelectric reference, but they calculate an offset by

measuring the voltage drop across the PN junction of a PNP transistor in close proximity

to the junction of the thermocouple wires and the meter terminals. The voltage drop

changes by -2.2 mV/°C. We specify the reference junction error as 0.5°C for an ambient

temperature of 10°C to 40°C. The signal conditioner board and PNP transistor are

calibrated as a system, so do not swap transistors. To minimize CJC errors, avoid air

turbulence around the PNP transistor.

5. Thermocouple wire errors. This the largest source of thermocouple reading errors, and

is caused by variations in the alloys found in commercial thermocouple wires. There are

variations from manufacturer to manufacturer, from batch to batch, and within batches.

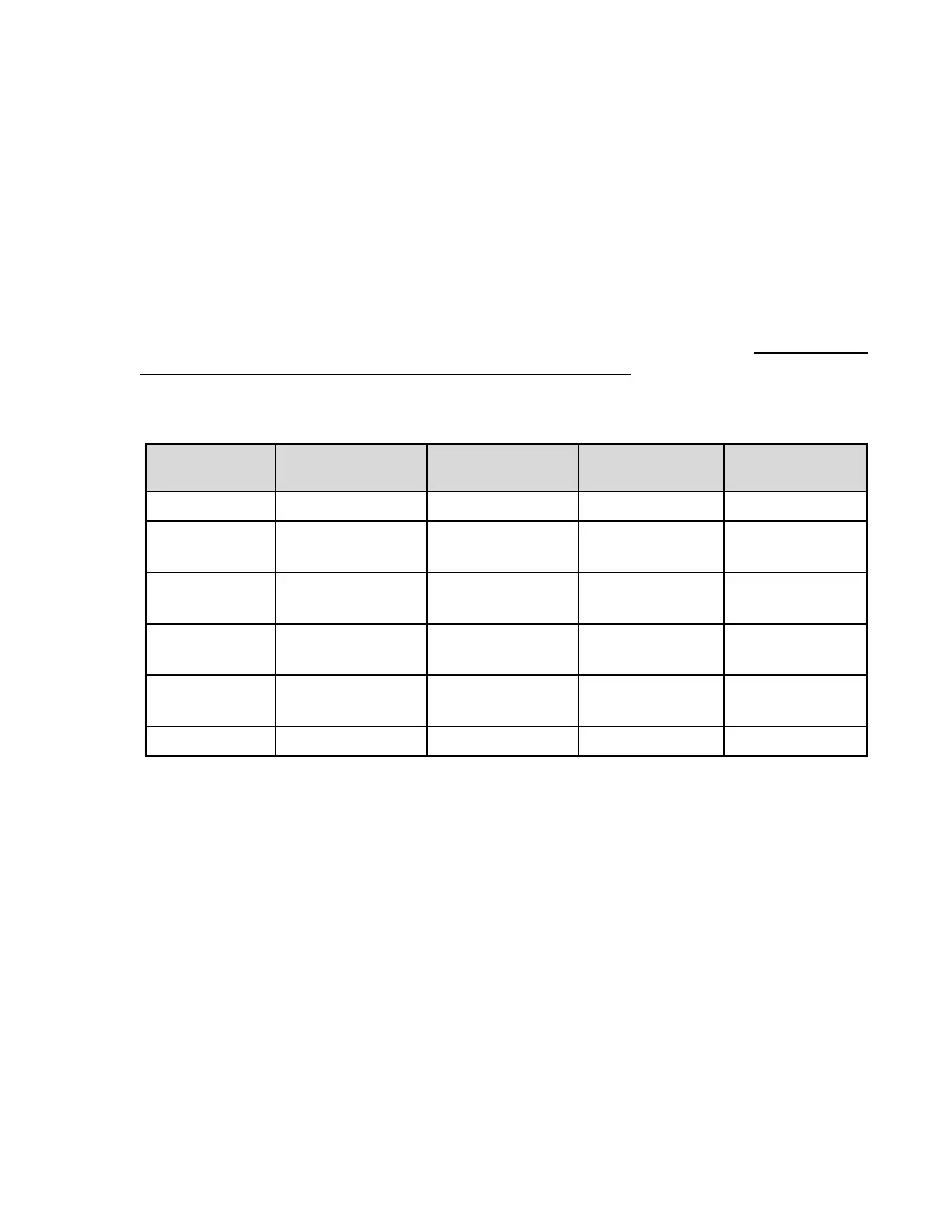

Shown below are the American Limits of Error ASTM E230-ANSI MC 96.1. These are the

error limits imposed on manufacturers of thermocouple wire, not error limits applicable to

a meter used with ideal thermocouple wire. The “Special Limit of Error” applies to more

expensive “Special Limits of Error” (SLE) thermocouple wire.

The “Limit or Error” tolerance to be used is the listed temperature or percentage,

whichever is greater. Tolerances expressed in °F are 1.8 times those in °C. Percentage

based tolerances are to be computed from temperatures expressed in °C.

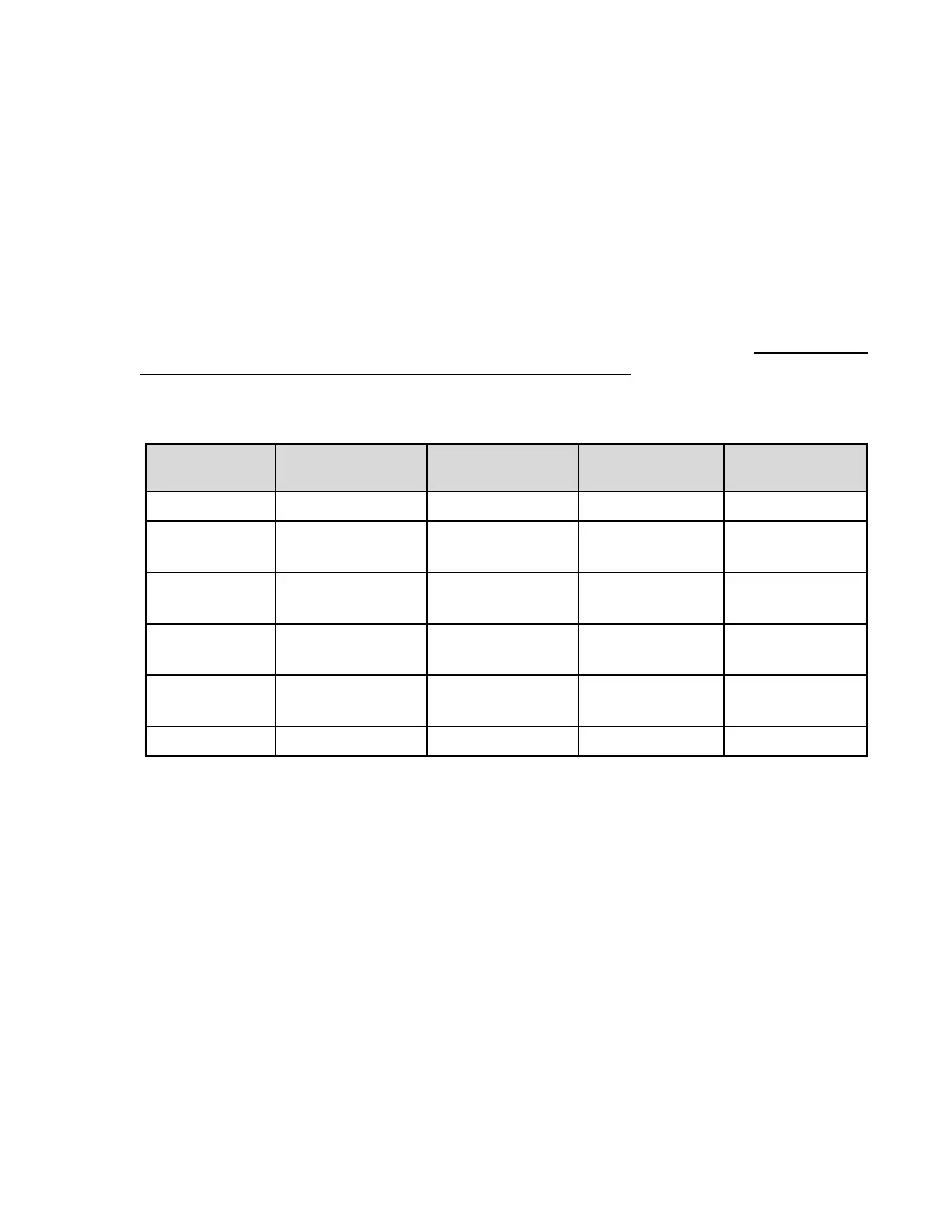

Tolerances in the above table apply to new, essentially homogeneous thermocouple wire,

normally 0.25 to 33 mm in diameter (30 to 8 AWG) and used at temperatures not

exceeding the upper temperature limits listed. If used at higher temperatures, these

tolerances do not apply. Thermocouples degrade with time, temperature, and exposure

to the environment.

Loading...

Loading...