- 34 -

15. RTD & RESISTANCE INPUT

The standard RTD and resistance signal conditioner board are jumper selectable for four RTD

types (DIN 100Ω platinum, ANSI 100Ω platinum, 120Ω nickel, 10Ω copper) and five resistance

ranges (from 20.000Ω to 200.00 kΩ). Fixed 2Ω, 2 MΩ or 20 MΩ resistance ranges require a

factory modified signal conditioner board where other ranges are no longer jumper selectable.

All ranges are factory calibrated with calibration factors stored in EEPROM on the signal

conditioner board. The meter software recognizes the board and will bring up the appropriate

menu items for it; however, it does not recognize the jumper settings. With RTDs, display in °C

or °F and resolution of 1°, 0.1° or 0.01° are user programmable.

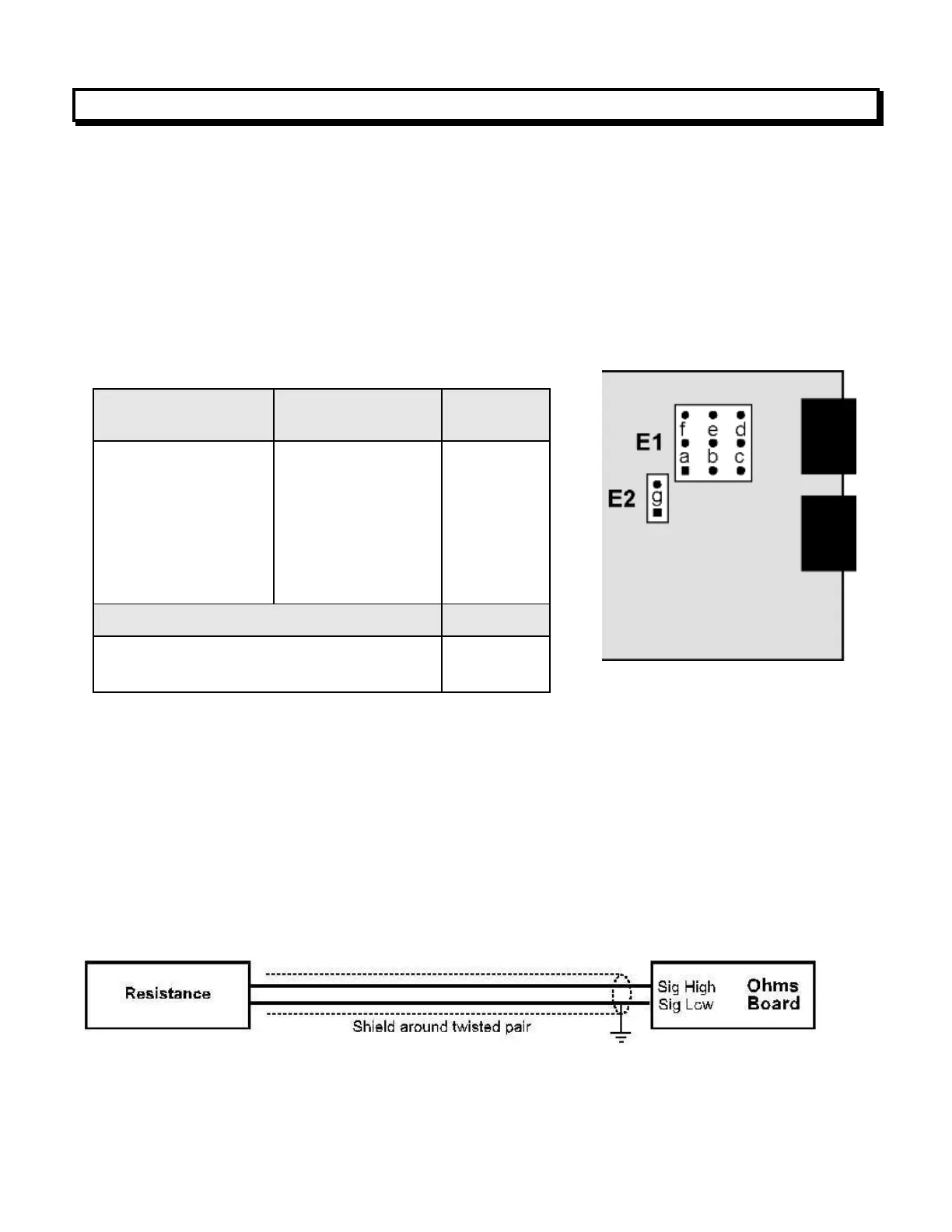

SIGNAL CONDITIONER BOARD SETUP VIA JUMPERS

1. Jumpers are installed on pins bridging letters.

2. Use 2.5 mm (0.1") jumpers.

3. Store unused jumpers on one pin so that one side is not connected.

SCALE & OFFSET SETUP

Scale is normally set to 1.0000. Scale can be used as an RTD resistance multiplier when the

actual resistance is other than nominal at 0°C. For example, if the resistance of a Pt100 RTD is

measured as 99.04 ohms at 0°C, you can apply a scale factor of 100 / 99.04 = 1.0097.

Offset allow the reading in degrees or ohms to be increased or decreased by a fixed amount.

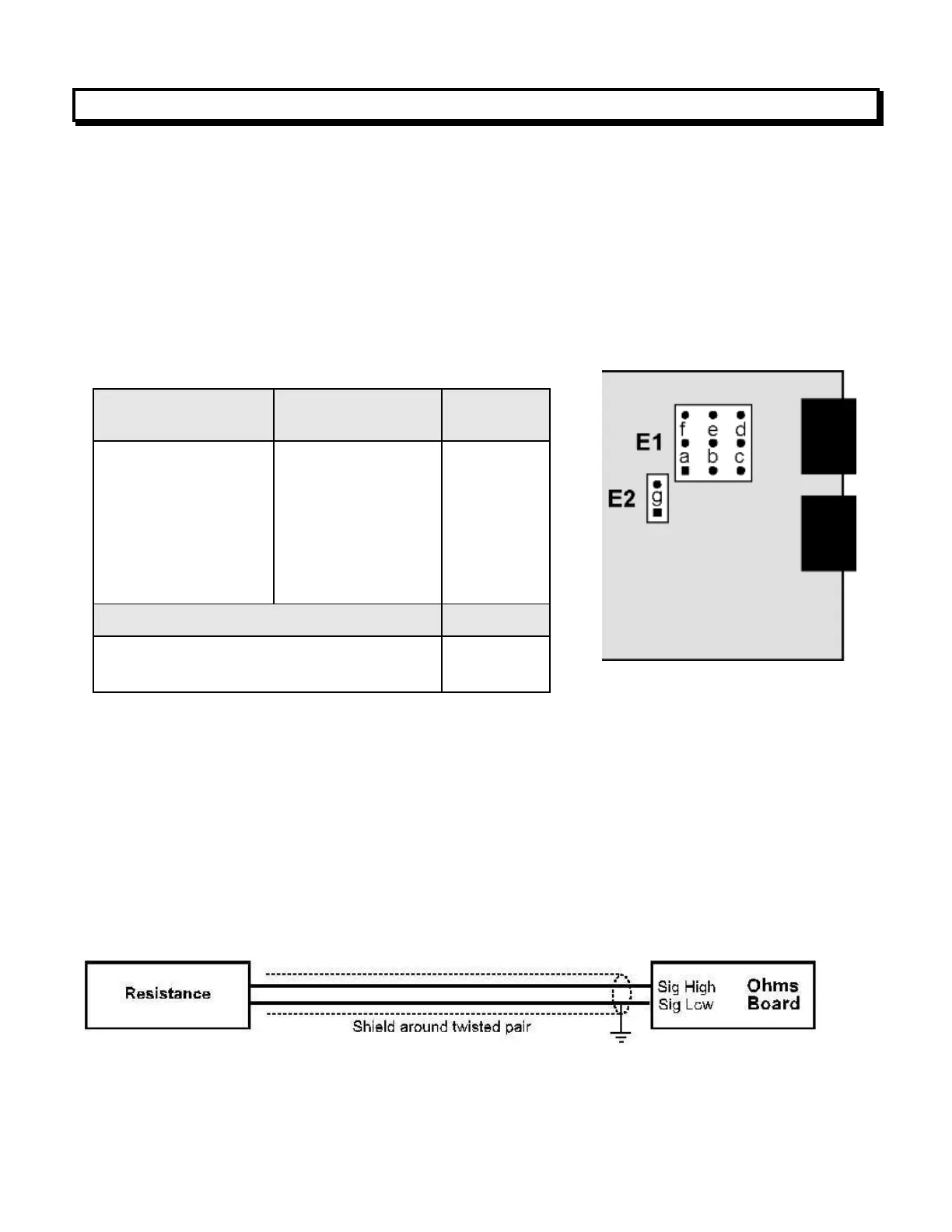

SIGNAL SHIELDING

Shielding for noise reduction

Ranges of 200 kΩ and above are susceptible to signal noise. To minimize noise pickup, the

input signal wiring should utilize a shielded twisted pair, and the shield should be connected to

signal low and earth ground at the meter, as illustrated.

Loading...

Loading...