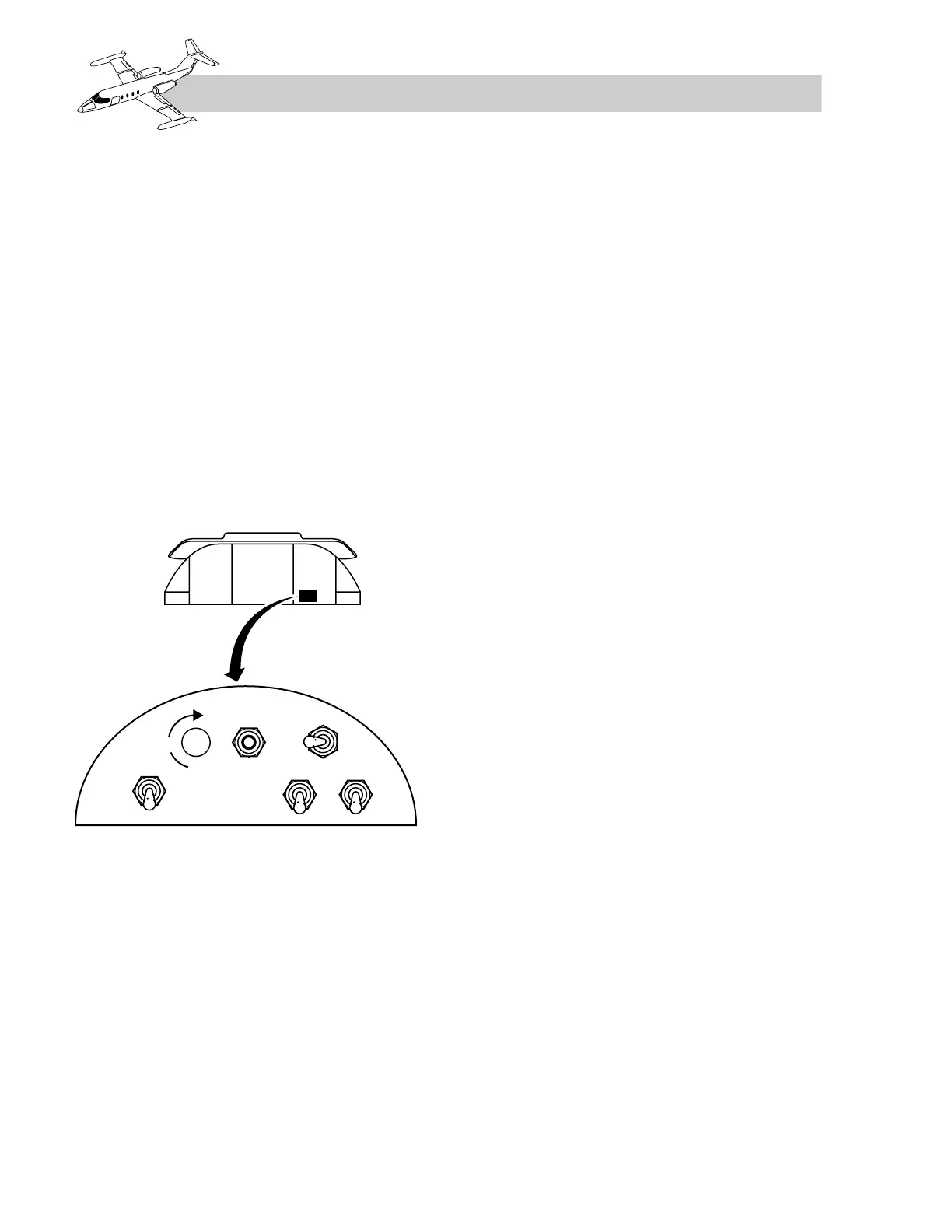

Flow Control Valve

The flow control valve admits air from the

bleed-air manifold and routes it to the heat ex-

changer for temperature control. The two

switches which control the valve are labeled

“AIR BLEED” and “NORM–MAX” (Figure

11-11). On models 23, 24, and 24B, the AIR

BLEED switch, when in ON, allows bleed air

to flow through the flow control valve, through

the heat exchanger to the venturi, and into the

cabin through the distribution ducts. The ven-

turi senses differential pressure which is sent

back to the flow control valve and modulates

the airflow in order to compensate for engine

power changes. The NORM–MAX airflow

switch, when positioned to MAX, opens the

flow control valve full open, allowing maxi-

mum airflow into the cabin.

Figure 11-11. AIR BLEED and NORM–

MAX Switches

Damper Valve

The damper valve is located just above the heat

exchanger in the ram-air inlet. The purpose of

the damper valve is to regulate the amount of

ram air passing through the ram-air scoops

across the heat exchanger and overboard, thereby

controlling the temperature of the bleed air for

cabin heating. The damper valve is operated by

the AUTO or MAN cabin heat control in the

cockpit. This valve requires approximately 27

seconds to travel from fully closed to fully open.

Heat Exchanger

The heat exchanger is a high-effectiveness,

two-pass crosscounterflow plate fin unit. High-

pressure bleed air is ducted into the heat

exchanger and routed through the core in cross-

counterflow directions. Ram air is routed over

the core channels and overboard just aft of

the tailcone access door. This results in a sub-

stantial reduction of bleed-air temperature.

Ram-Air Ventilation

In the event that the aircraft is unpressurized

in flight, air for circulation and ventilation of

the cabin and cockpit areas is provided by ram

air ducted into the conditioned bleed-air

distribution system.

During the normal operation, a one-way check

valve in the connecting ram-air duct prevents

loss of conditioned pressurization bleed air

through the ram-air plenum exhaust port.

Cabin and Cockpit

Air Distribution

Conditioned airflow distribution to the cabin

and cockpit areas is essentially the same for all

aircraft (see Figure 11-1). The conditioned air

is routed from the tailcone into the cabin area

through two ducts, one on each side of the

cabin. The left duct ends at the entry door, and

the right duct continues forward to the cockpit.

A footwarmer diffuser, located below the

instrument panel just forward of the center

pedestal, directs continuous conditioned air

along the center floor. Two piccolo tubes

(SNs 24-165 and subsequent and all model

25s), installed vertically on each side of the

windshield center support structure, direct a

continuous flow of conditioned air across the

forward section of each pilot’s windshield for

interior windshield defogging.

Temperature Control

Cabin temperature control is accomplished by

conditioning the engine bleed air, which is also

used for cabin pressurization. The cabin heat-

ing system can be controlled both manually

11-12

FOR TRAINING PURPOSES ONLY

Loading...

Loading...