4

Fill the primer feed tray. View help video here for loading primers into tray: leeprecision.com/pro-1000-help-videos.html

Don’t let the primer level fall below the tray level. Running out of primers will cause a mess inside your shell plate carrier. Once the last primer

has exited the folding tray, replenish the primer supply, else you will load cases without primers.

DANGER: Use only CCI™ or Remington™ brand primers. Other brands, espec ially Federal™, can explode with sucient force to seriously injure the

user or persons nearby.

ALL PRIMERS ARE DANGEROUS and it should be anticipated that the primers in the tray could explode through accident, misuse or spontaneously. Should

an explosion occur, our tests have demonstrated that safety glasses will normally prevent serious injury to the user if CCI™ or Remington™ primers are

used, because the explosion is minimal. Other primers, however, can explode with sucient force to seriously injure the user, or persons nearby. We do not

take any position with respect to the quality of performance of primers available on the market. However, ONLY those primers manufactured by CCI™ or

Remington™ are recommended for use in the Pro 1000—and when loading those primers—safety glasses and hearing protection must be used. NO OTHER

PRIMERS should be used with the Pro 1000.

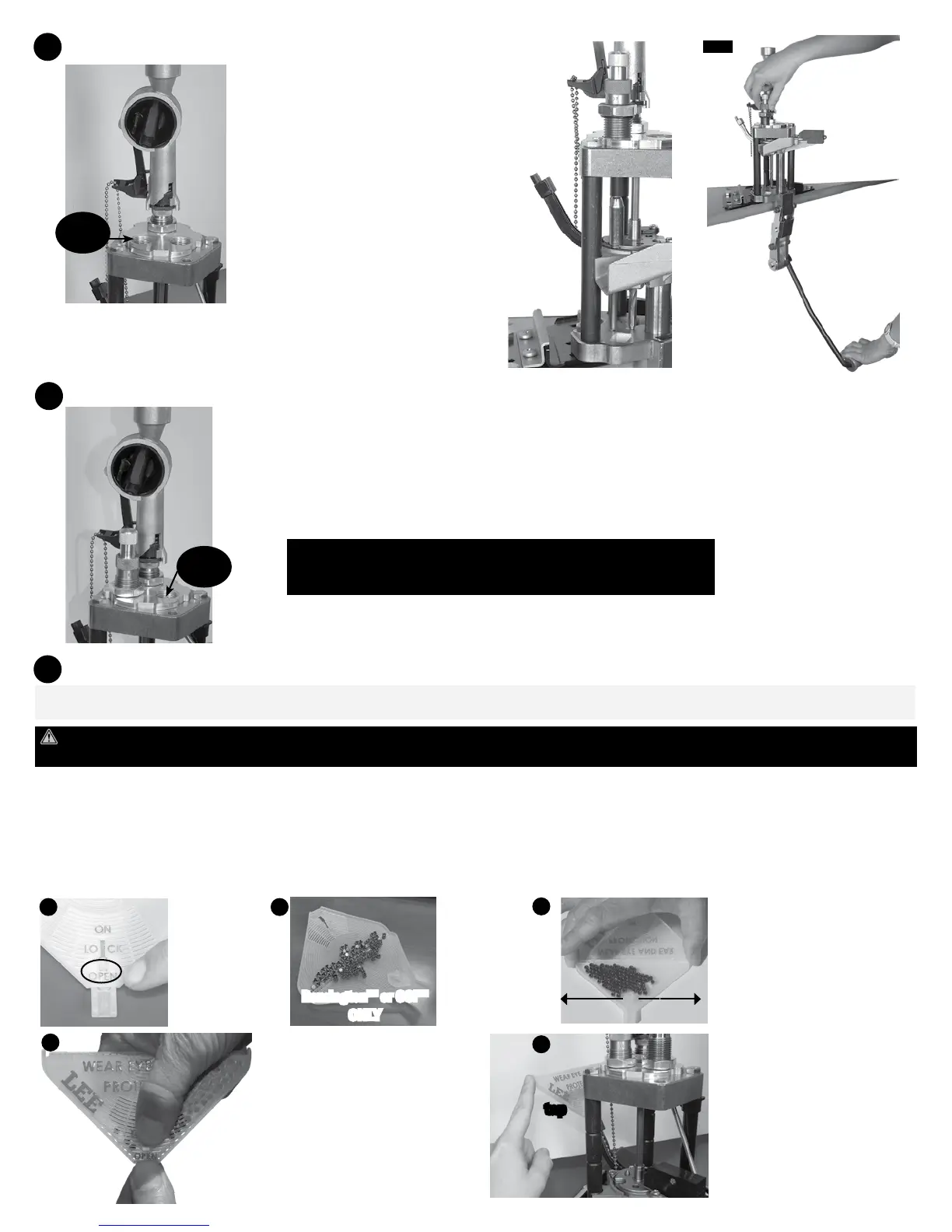

Slide the flow

control to

OPEN.

Randomly

deposit

primers.

Lift tray so output spout touches table,

shake tray side to side to upright all the

primers. Allow cover to naturally fold

up, notice how the primers glide across

hinge upright themselves and work

their way to wards the outlet.

Fold cover over, slide the flow control

to LOCK position, feel for the detent.

Grasp the top and bottom of the flow

control valve using your thumb and

index finger above and below tray.

NOTE: make sure it is in the LOCK

detent position, else primers may

spill.

Slide the tray into the trough. Slide the

flow control to the ON position. Tap the

side of the tray several times to fill the

trough.

tap

10

A

B

C

D

E

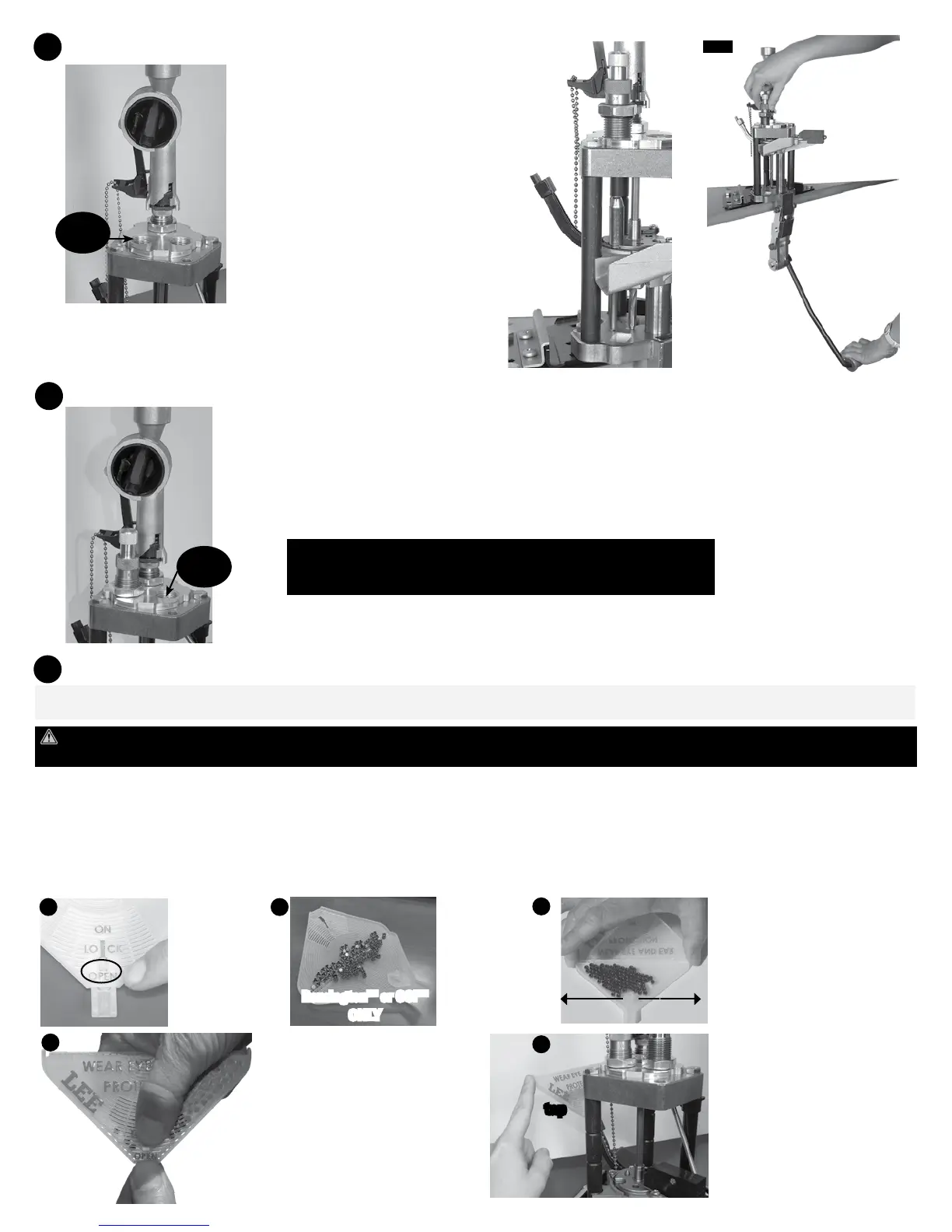

Lower the press lever (shell plate carrier up).

Screw the full length sizer in to position # 1 until it touches the shell plate, lower the shell plate

carrier, screw the die in an additional turn. Raise the shell plate carrier and tighten the lock ring

finger tight.

9

position

1

Remington™ or CCI™

ONLY

Spin the lock-ring up to the top of the die

and unscrew the adjusting screw out five full

turns. Put the press lever in the up position

(shell plate carrier down). Place a loaded

round that you wish to duplicate in turret

position # 3.

[FIG 11] Raise the shell plate carrier to the top

of its stroke and hold (shell plate carrier up).

Screw the bullet seating die in until it stops

turning, lower the shell plate carrier slightly,

thread die in an additional 1/8 turn. Finger

tighten the lock ring. Now raise the shell plate

carrier to the top of its stroke, screw the bullet

seating adjusting screw in until you feel it

touch the tip of the bullet.

position

3

8

FIG 11

Consult your powder measure instructions and reloading die instructions for

setting the charge on your (Auto-Drum Powder Measure, instructions pg. 2) or

(Pro Auto-Disk Powder Measure, back side of instruction sheet)

Full Length Sizing Die (position # 1)

BULLET SEATING DIE (position # 3)

Loading...

Loading...