motor current rating

P108 =

SM2 output rating

x 100

Example: motor = 3 amps; SM2 = 4

amps; P108 = 75%

Note

Do not set above the rated motor current as listed on the motor dataplate.

The motor thermal overload function of the SM2 is UL approved as a

motor protection device. If line power is cycled, the motor thermal state

is reset to cold state. Cycling power after an overload fault could result in

significantly reducing the motor life.

16

Commissioning

Code Possible Settings

IMPORTANT

No. Name Default Selection

P102

Minimum

Frequency

0.0 0.0 {Hz} P103 • P102, P103 are active for all speed

references

• When using an analog speed

reference, also see P160, P161

p103

Maximum

Frequency

60.0 7.5 {Hz} 500

Note

• P103 cannot be set below Minimum Frequency (P102)

• To set P103 above 120 Hz:

- Scroll up to 120 Hz; display shows

HiFr (flashing).

- Release button and wait one second

- Press

button again to continue increasing P103

WARNING!

Consult motor/machine manufacturer before operating above rated frequency. Overspeeding the

motor/machine may cause damage to equipment and injury to personnel!

P104

Acceleration

Time 1

20.0 0.0 {s} 3600 • P104 = time of frequency change

from 0 Hz to P167 (base frequency)

• P105 = time of frequency change

from P167 to 0 Hz

• For S-ramp accel/decel, adjust P106

P105

Deceleration

Time 1

20.0 0.0 {s} 3600

Example: if P103 = 120 Hz, P104 = 20.0 s and P167 (base frequency) = 60 Hz;

rate of frequency change from 0 Hz to 120 Hz = 40.0 s

P106

S-Ramp

Integration Time

0.0 0.0 {s} 50.0 • P106 = 0.0: Linear accel/decel ramp

• P106 > 0.0: Adjusts S-ramp curve

for smoother ramp

p107

(1)

Line Voltage

Selection

1* 0 Low (120, 200, 400, 480VAC) * The default setting is 1 for all

drives except when using “reset

50” (Parameter P199, selection 4)

with 480V models. In this case, the

default setting is 0.

1 High (120, 240, 480, 600VAC)

p108

Motor Overload 100 30 {%} 100

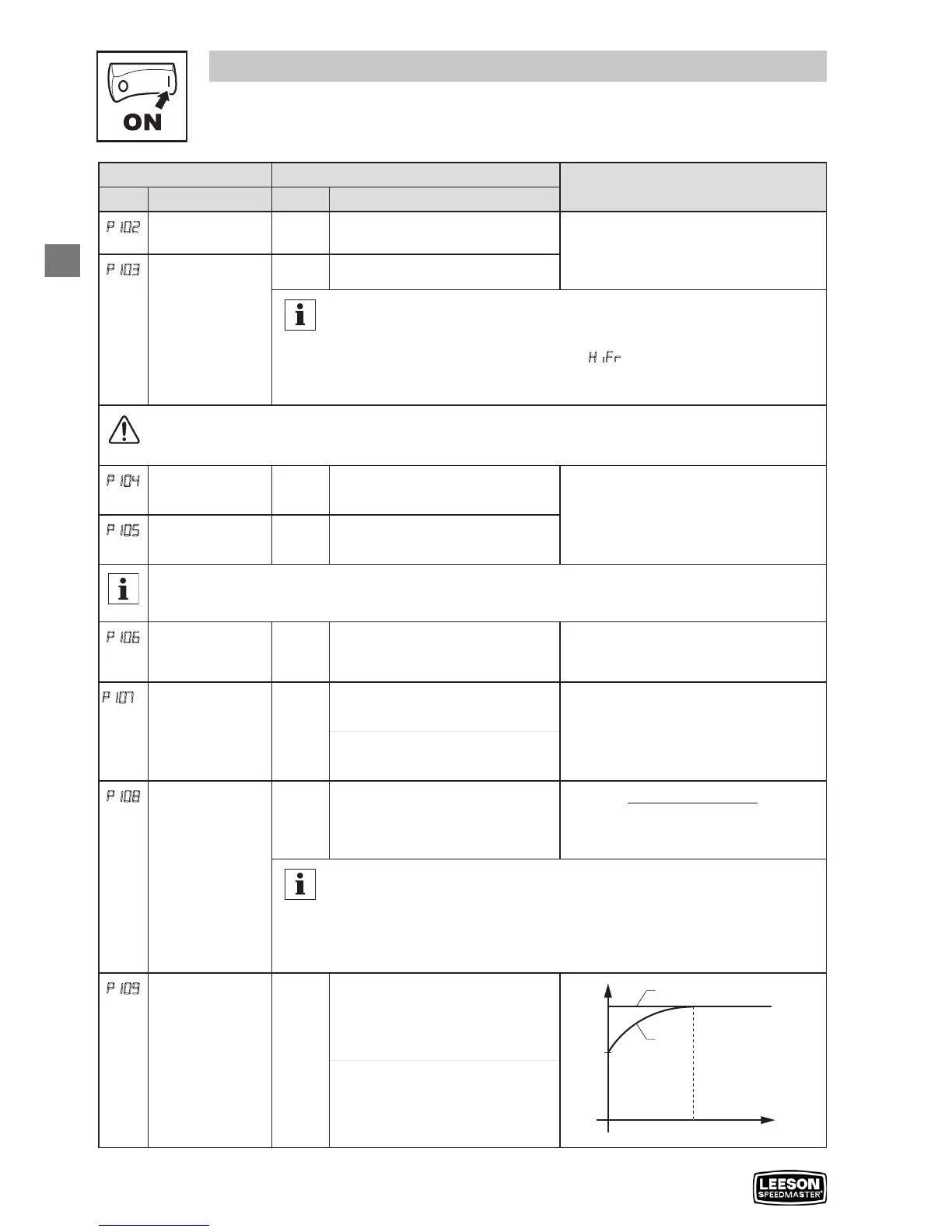

P109

Motor Overload

Type

0 0 Speed Compensation

Loading...

Loading...