13

Chapter 3Frame Mortise & Tenon Jig User Guide

THE FMT PRO JIG

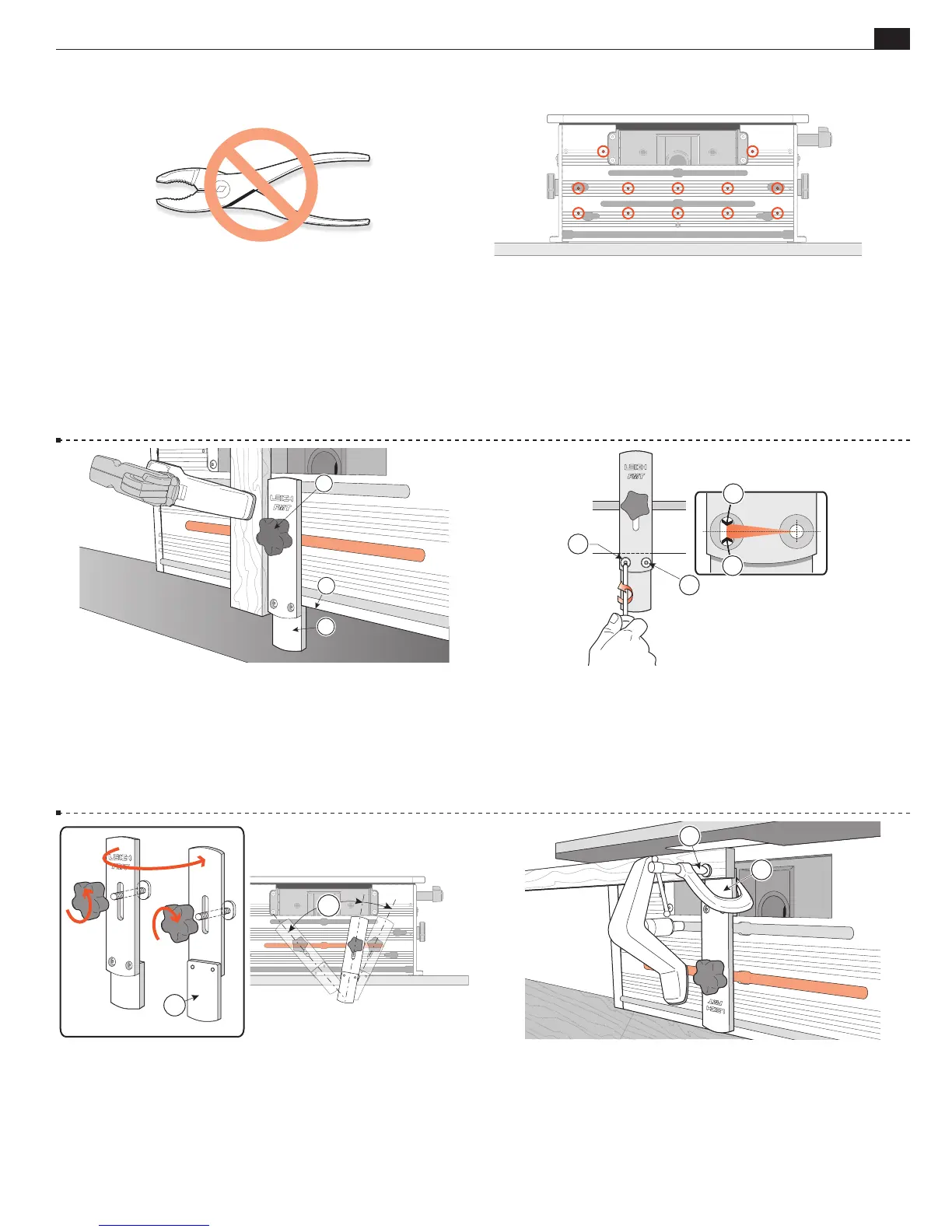

3-11 The clamp T-bolts nuts need only be lightly finger tightened

to prevent accidental clamp movement. The nuts are knurled to

provide a good finger grip.

Never use a tool to tighten these nuts!

3-12 The clamp plate is provided with twelve through-holes.

If for any reason a facing board is required to be attached to the

clamp plate, No.8 or M4 wood screws (not supplied) may be used

from the rear. See chapter 4, Small Joints.

3-13 The FMT Pro’s sidestop fence is attached in all modes by a

single knob and T-bolt inserted to the center clamp plate slot

➀

.

Most tenon pieces are routed vertically, and for that purpose the

short part of the fence

➁

acts as a T-square against the edge of the

clamp plate

➂

. In this mode the Leigh logo faces toward you.

1

3

2

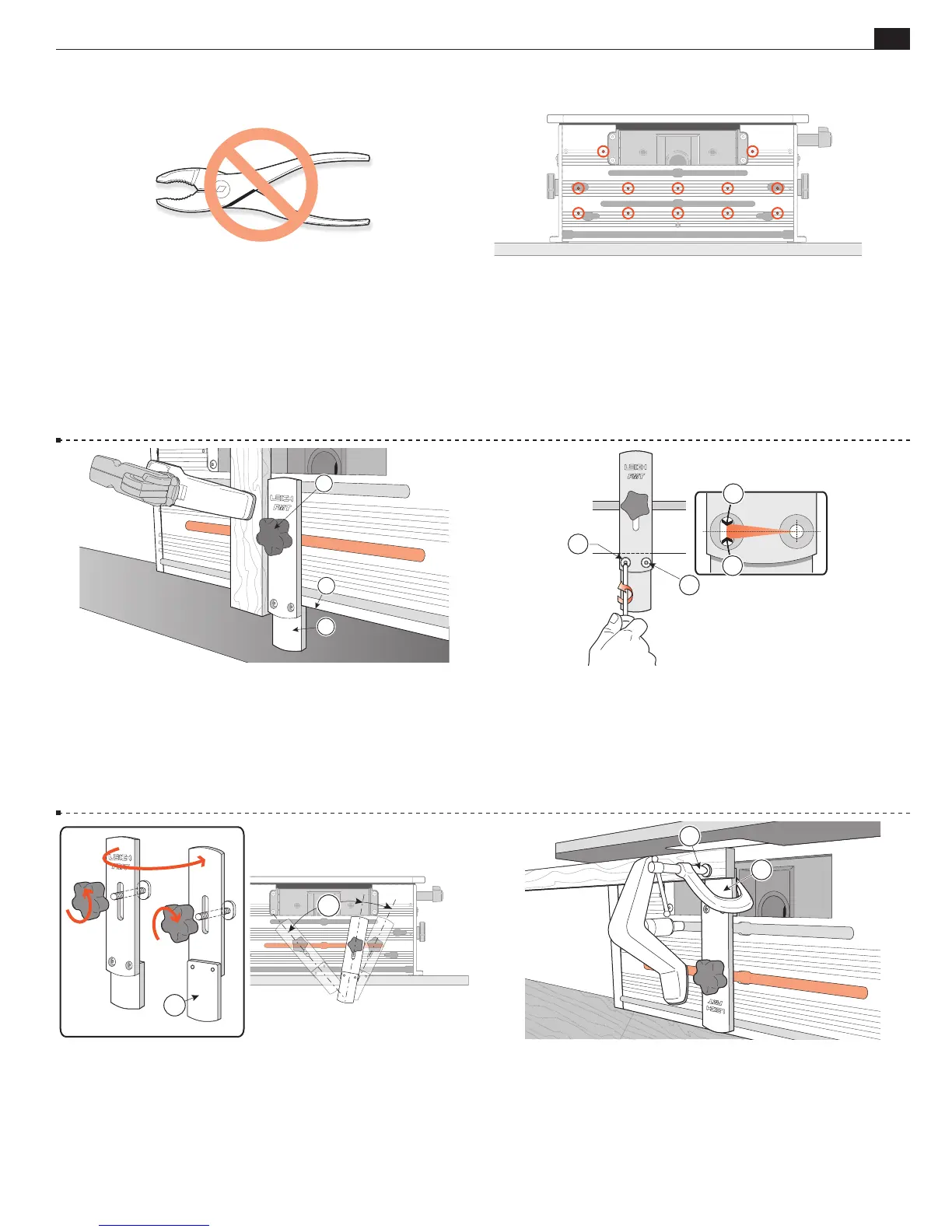

3-14 The sidestop fence is squared at the factory, but check your first

test joints. If your router/bit is not perfectly perpendicular to the table

adjust the sidestop fence: slightly loosen the 'pivot' screw

➀

and the 'lock'

screw

➁

. Adjust the angle

➂

to match the bit and retighten. Rout test

joints to confirm correct setting. Once locked in this position it should

never need adjusting when used with that same router.

1

2

3

3

3-15 Angled Joints: Remove the knob and T-bolt. Reverse the fence so

the short end faces toward you

➀

. The fence may now be set at any angle

along the center clamp plate slot

➁

by tightening the knob.

m NOTE: Never rout tenons with the short part of the fence to the top, in

the bit opening.

2

1

3-16 'Mortise steady': When routing mortises in small stock the piece

may 'flutter' causing poor joint fit. Invert the fence with the short end

up in the bit opening

➀

. Clamp the mortise piece against the face of the

short fence

➁

which is perfectly flush with the clamp plate face

➀

. When

routing mortises at the end of a board, always move the table as far as

possible left or right to minimize the length of unsupported workpiece.

2

1

Loading...

Loading...