Frame Mortise & Tenon Jig User Guide

42

Chapter 6

WORKPIECE AND JOINT OPTIONS

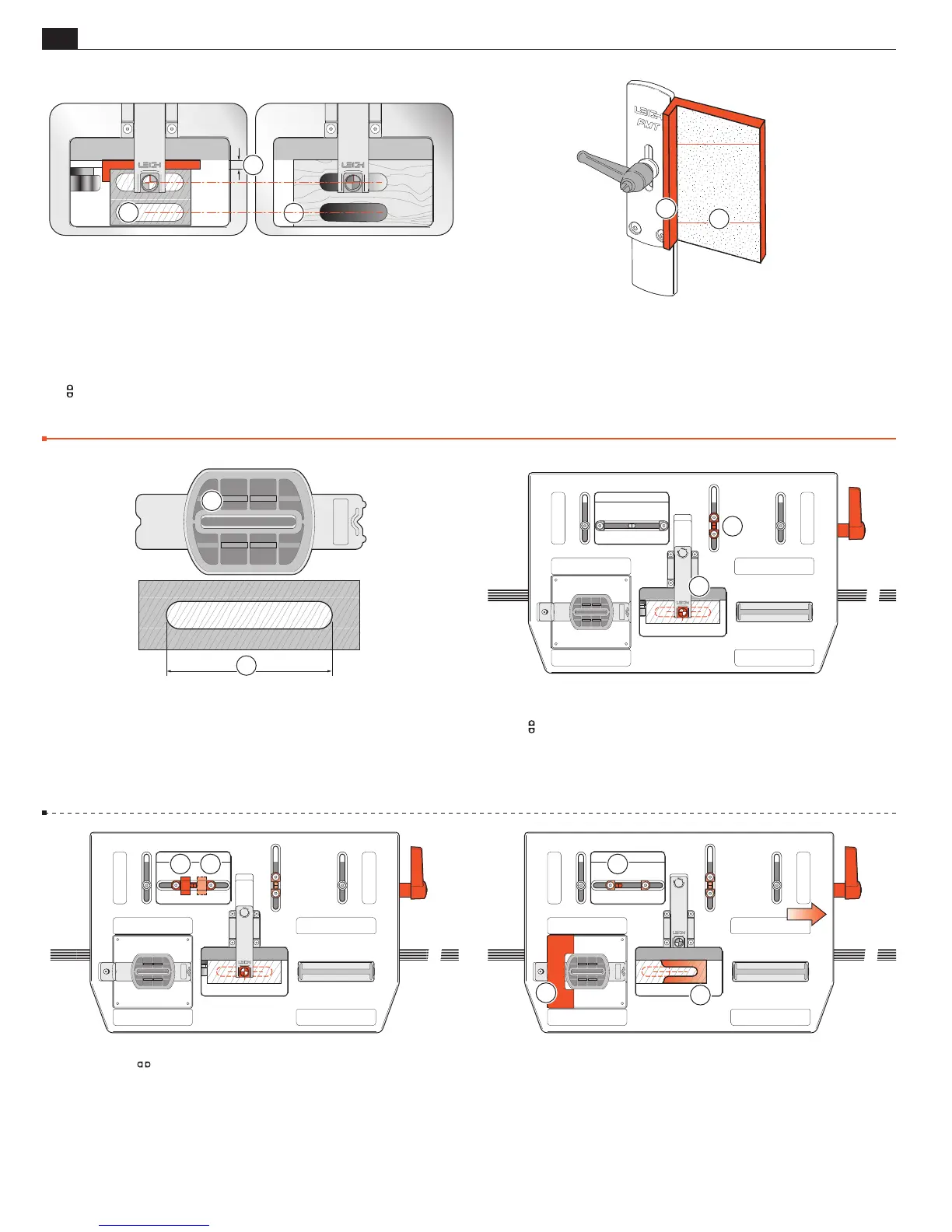

6-3 Side-by-side double and quadruple joints of different stock

thicknesses require a packing piece (see 6-4) between the clamp plate

and tenon piece, the thickness equal to the offset of the two pieces.

For example, a 2"[50mm] tenon piece

➀

centered on a 3"[75mm]

mortise piece

➁

will require a

1

⁄2"[12,5mm] packing piece

➂

. m Never

attempt to achieve this alignment by re-sighting the joint and resetting

the

limit stops. That would make it impossible to guarantee

twin-tenon to mortise alignment.

3

1

2

6-4 This packing piece should include its own side-stop fence

➀

and if required frequently, should have sandpaper glued onto its

outer surface for secure workpiece clamping

➁

.

Sight and rout the tenons in the usual way with the packing piece

in place. Then, remove the packing piece before sighting and

routing the mortises.

■

1

2

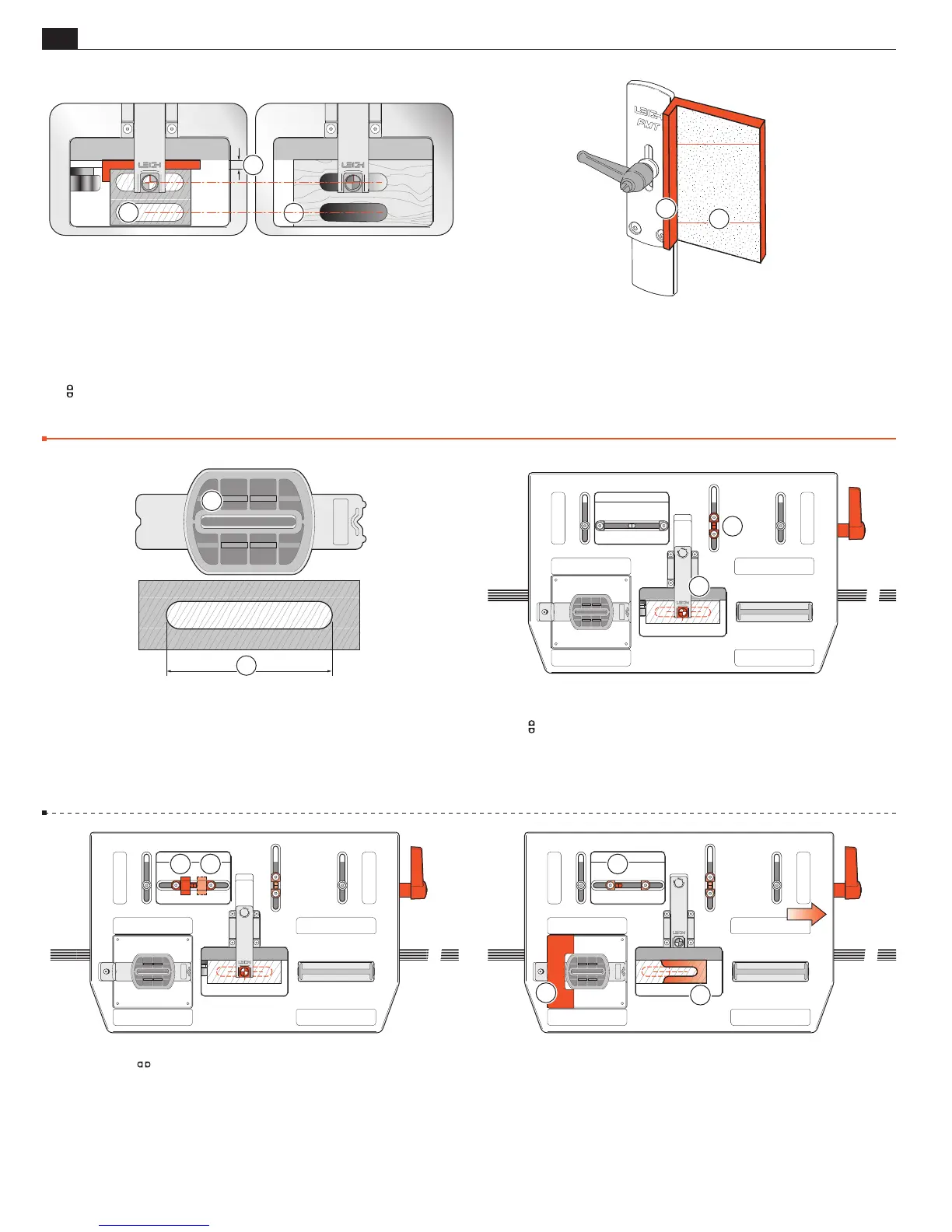

6-5 The FMT Pro table movement allows for easy routing of odd-

sized joints. For example, you may want to rout a 3"[75mm] joint

➁

and you only have a 2"[50mm] guide

➀

. Use this simple formula:

Joint, minus Guide, divided by 2.

Example: 3" - 2"

÷ 2 =

1

⁄2"[75 - 50 ÷ 2 = 12,5mm]

Cut a small block equal to the result; in this example,

1

⁄2"[12,5mm].

Longer and Shorter Joints

1

2

6-6 Tenons Mark the center as before.

Position and sight the tenon

➀

, and lock the table.

Set the

stops against the post

➁

.

1

2

6-7 Set the

stops one at a time with the small block

between the stops and post

➀➁

. This ensures that the table move-

ment is centered about the joint center-mark on the stock. Remove

the block, but save it.

12

6-8 To rout the wider tenon:

- Move the table right, to the stop

➀

.

- Rout the right-hand end of the tenon

➁

.

Use a guard in the left end of the guide recess if necessary

➂

.

1

2

3

Loading...

Loading...