Frame Mortise & Tenon Jig User Guide

50

Chapter 7

SPECIAL JOINTS

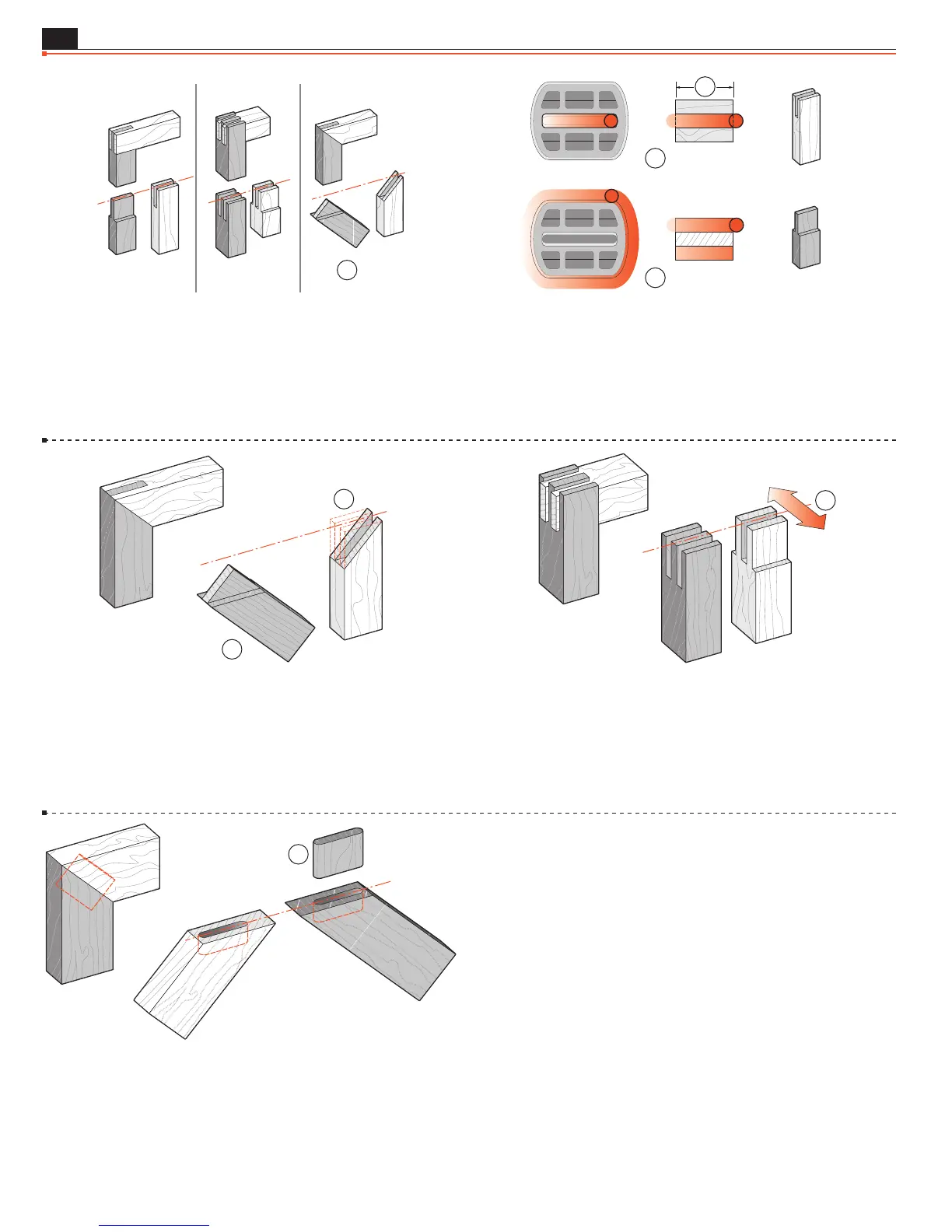

7-19 Floating Tenons A “floating” tenon in a mitered corner

allows for a greater joint glue area at the inside of the corner. On

this mitred corner, the workpieces are mounted in the jig at 45˚

and the mortises routed. The floating tenon

➀

is routed on the

end of a vertically mounted scrap piece using the same guide and

then sawn off.

■

1

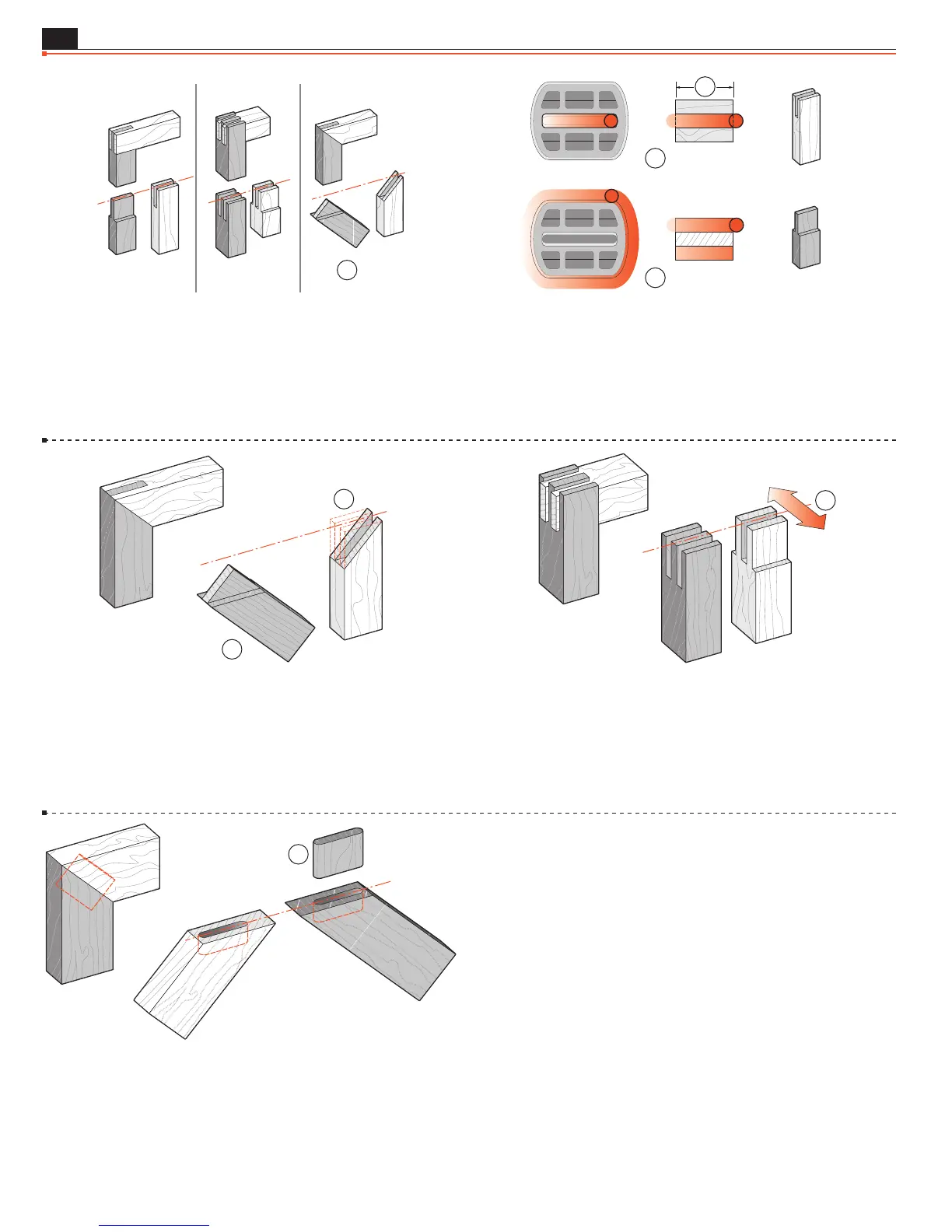

7-15 Routing bridle joints on the FMT Pro is simple. All the work-

pieces (with the exception of the mitered tenon)

➀

are mounted

vertically on the jig.

1

7-16 Select a guide that is greater in length than the workpiece

width

➀

by at least two bit diameters. Rout right through the

“vertical mortise”

➁

and across the tenon sides

➂

. The bit will

clear the edge of the workpiece before the guide pin reaches the

rounded part of the guide.

MORTISE

TENON

2

3

1

7-17 The mitered “tenon” is mounted at 45˚ on the clamp plate

➀

.

The “mortise” end miter

➁

is cut on the table saw after routing

the mortise.

1

2

7-18 Twin bridle joints use the technique described above com-

bined with the table movement

➀

(see 5-12, Twin Joints).

1

Bridle Joints

Loading...

Loading...