EN-16

7 MAINTENANCE

• Correct machine servicing is vital for ensuring reliable

and safe operation.

7.1 Maintenance after operation

- Clean the machine thoroughly.

- Grease the machine with an anti-corrosion agent.

Pay special attention to the tines. Smooth tines without any rust

stimulate an unhampered crop flow.

- Grease the piston rod with an anti-corrosion agent if the machine

will not be used for a long period.

Remove the agent before using the machine again. If not, the ram

seal may be affected if the anti-corrosion agent hardens.

7.2 Lubrication

All lubrication points of the machine can be greased with a bio-

degradable grease (Total Biomultis SEP2), unless stated otherwise.

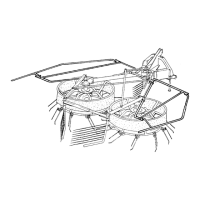

- PTO shafts must be greased every 8 working hours via the grease

nipples on the cross assemblies, protection tubes and slip clutch

(fig. 15).

- Grease the profiled tubes of the PTO shaft every 8 working hours

(fig. 15).

- Grease the cross assemblies of the double universal joints every 8

working hours (fig. 16).

- Grease the pivot points of the drive every 40 working hours

(fig. 17).

Loading...

Loading...