EN-18

7.3 Periodic maintenance

Periodic maintenance must be carried out:

• at the start of the raking season;

• before prolonged storage of the machine;

• when the machine is used extensively during the season.

- Grease all points of the machine listed in § 7.2 “Lubrication”.

- Grease the spring-loaded locking pins of the yoke lock of the PTO

shaft.

- Check if the PTO shaft telescopes smoothly.

A damaged PTO shaft may cause excessive wear and tear to the

machine and tractor.

- Check the machine for any damage and defects. Repair or replace

damaged parts.

- Check the hydraulic system for leaks and damaged parts. Repair or

replace damaged parts.

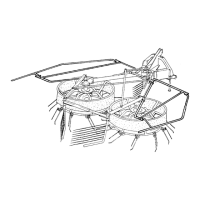

- Check the gearbox for grease leakage (fig. 21).

The grease does not need to be replaced. In the event of any

grease loss, top up with SHELL ALVANIA WR-0 (max. 0.33 kg).

Replace the grease if it is contaminated by water or is no longer

compliant due to another cause.

When mounting the cover, lubricate the edge of the gearbox and

the bolt holes with a fluid gasket (LOCTITE 574).

An incorrect quantity of grease may lead to overheating

and cause irreparable damage to the gearbox.

- Check the tyre pressure (fig. 22).

- Check all bolts and nuts for tightness.

Tighten loose bolts/nuts to the torques specified below.

M6 M8 M10 M12 M14 M16 M20 M24

Nm 10 25 50 85 135 215 410 710

kgm 1.0 2.5 5.0 8.5 13.5 21.5 41.0 71.0

Loading...

Loading...