Page 5

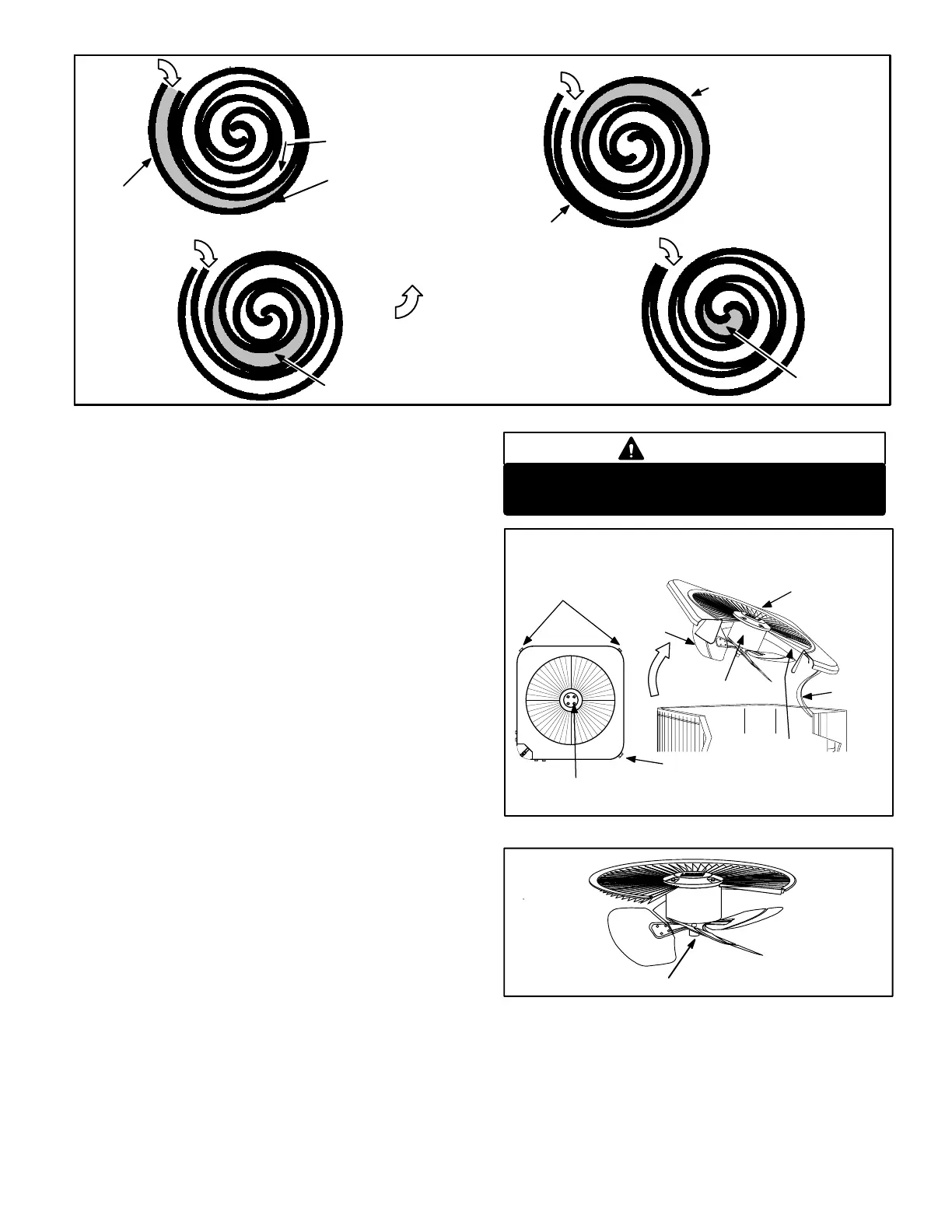

1

2

3

4

SUCTION

POCKET

SUCTION

ORBITING SCROLL

STATIONARY SCROLL

SUCTION

SUCTION

DISCHARGE

POCKET

SUCTION

INTERMEDIATE PRESSURE

GAS

CRESCENT

SHAPED

GAS POCKET

HIGH PRESSURE GAS

FLANKS SEALED

BY CENTRIFUGAL

FORCE

MOVEMENT OF ORBIT

FIGURE 6

Due to its efficiency, the scroll compressor is capable of draw

ing a much deeper vacuum than reciprocating compres

sors. Deep vacuum operation can cause internal fusite

arcing resulting in damaged internal parts and will result

in compressor failure. Never use a scroll compressor for

evacuating or to pump system into a vacuum. This type

of damage can be detected and will result in denial of

warranty claims.

The scroll compressor is quieter than a reciprocating com

pressor, however, the two compressors have much different

sound characteristics. The sounds made by a scroll com

pressor do not affect system reliability, performance, or indi

cate damage.

See compressor nameplate or ELECTRICAL DATA for

compressor specifications.

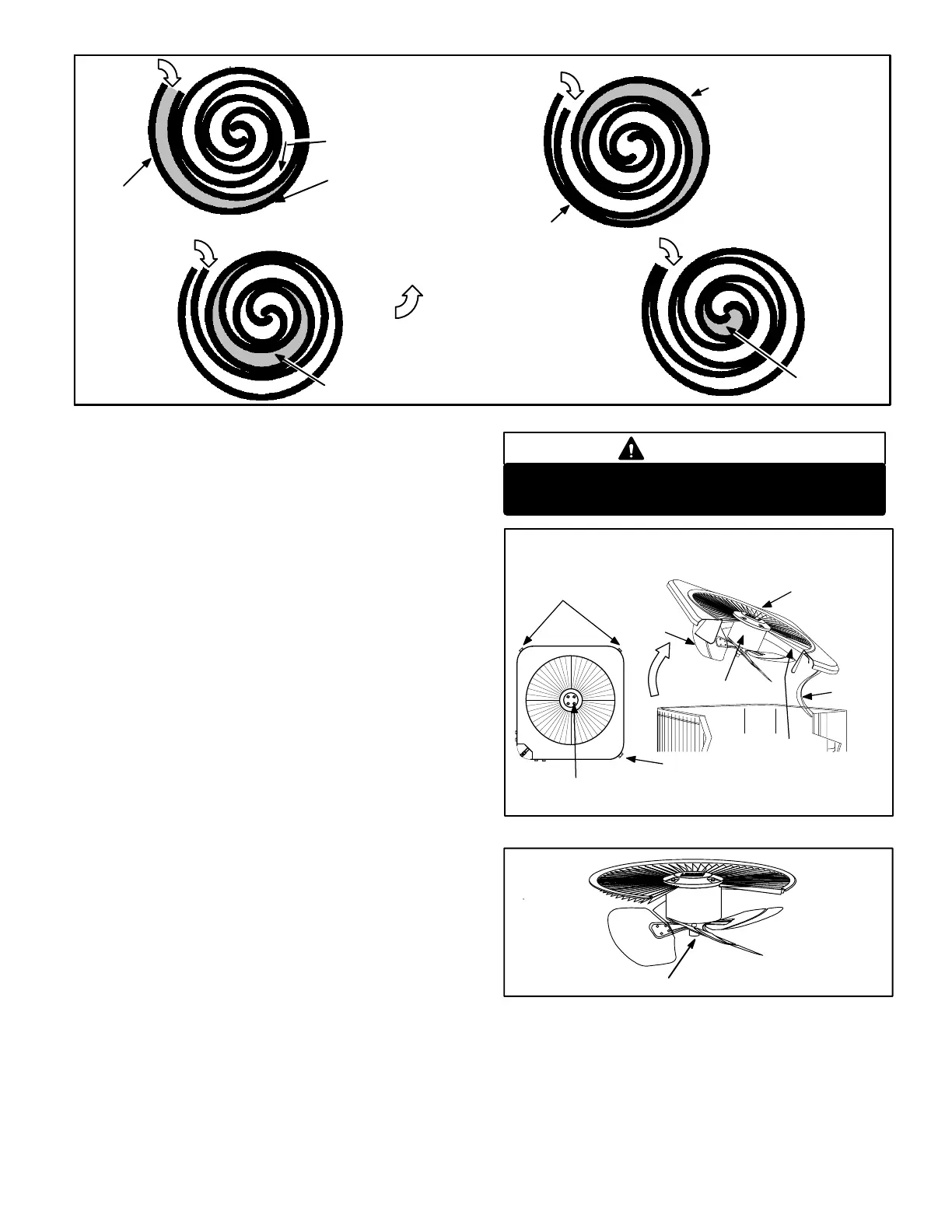

C − Condenser Fan Motor

All units use single−phase PSC fan motors which require a run

capacitor. In all units, the condenser fan is controlled by

the compressor contactor.

ELECTRICAL DATA tables in this manual show specifi

cations for condenser fans used in 13ACCs.

Access to the condenser fan motor on all units is gained

by removing the seven screws securing the fan assem

bly. See figure 7. The condenser fan motor is removed

from the fan guard by removing the four nuts found on

the top panel. Drip loops should be used in wiring when

servicing motor. See figure 8 if condenser fan motor re

placement is necessary.

Make sure all power is disconnected before

beginning electrical service procedures.

DANGER

FAN

CONDENSER FAN MOTOR

AND COMPRESSOR ACCESS

Remove (7) screws

REMOVE (7) SCREWS

SECURING FAN GUARD.

REMOVE FAN GUARD/FAN

ASSEMBLY.

MOTOR

FAN GUARD

WIRING

FIGURE 7

RACEWAY

Remove (4) nuts

ALIGN FAN HUB FLUSH WITH END OF SHAFT

FIGURE 8

Loading...

Loading...