Page 16

506374−01 03/10

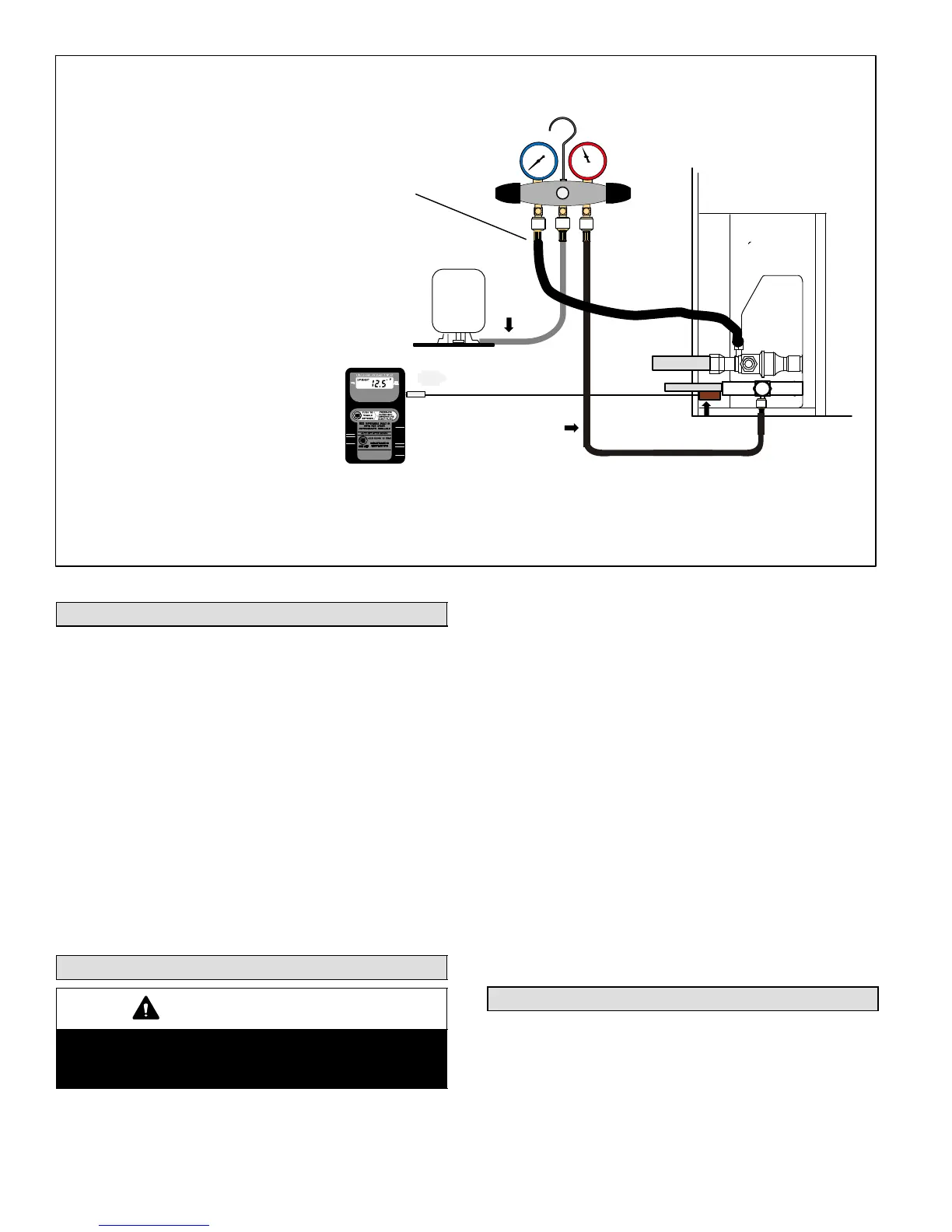

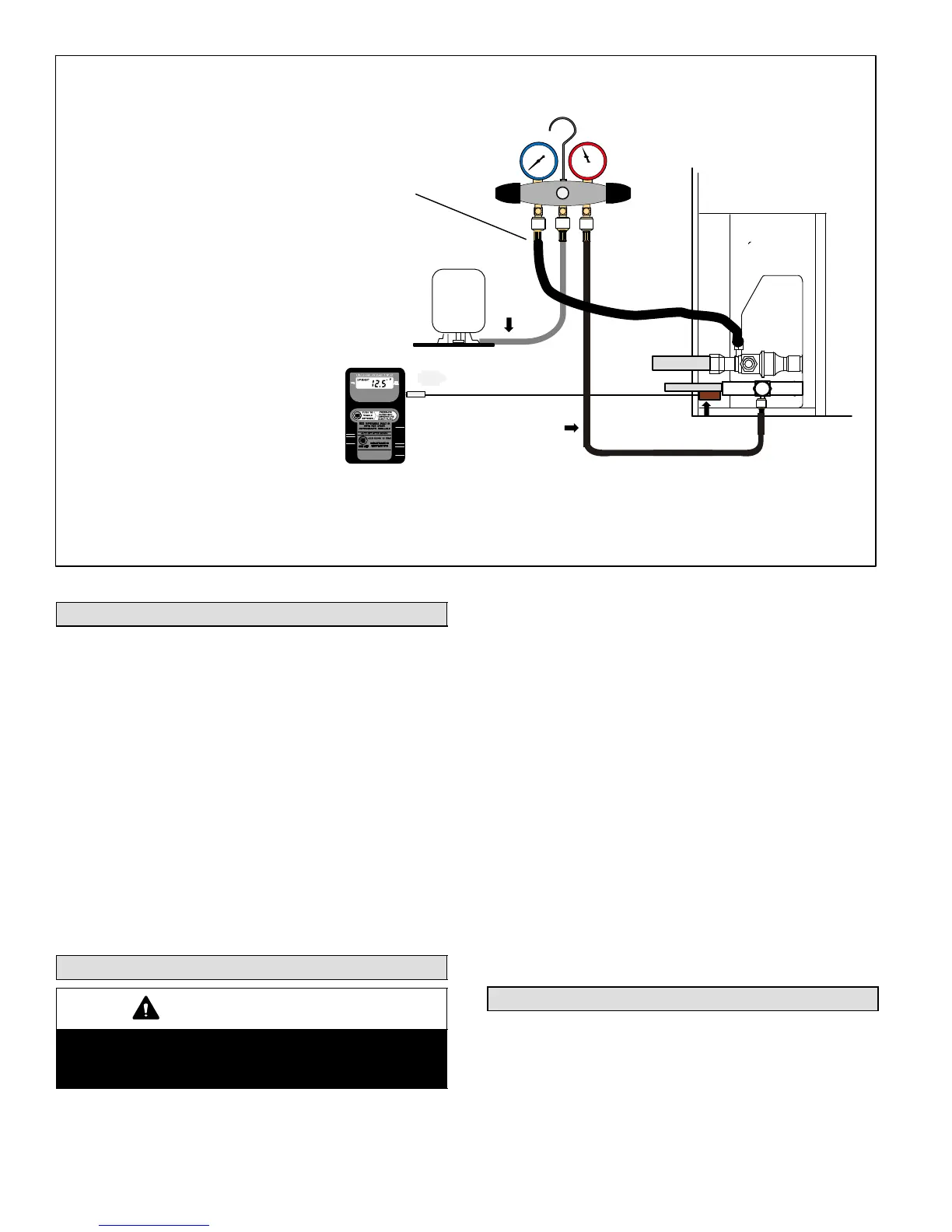

TO LIQUID

LINE SERVICE

VALVE

TEMPERATURE

SENSOR

DIGITAL SCALE

REFRIGERANT TANK

TEMPERATURE SENSOR

(LIQUID LINE)

MANIFOLD GAUGE SET

A. Close manifold gauge set valves and connect the center hose to a cylinder of HFC−410A. Set for liquid phase charging.

B. Connect the manifold gauge set’s low pressure side to the suction line service port.

C. Connect the manifold gauge set’s high pressure side to the liquid line service port.

D. Position temperature sensor on liquid line near liquid line service port.

OUTDOOR UNIT

CHARGE IN

LIQUID PHASE

CONNECTIONS FOR TESTING AND CHARGING

GAUGE SET

A

C

D

LOW

HIGH

B

SUCTION LINE

SERVICE PORT

CONNECTION

Figure 9. Gauge Set Setup and Connections

Servicing Units Delivered Void of Charge

If the outdoor unit is void of refrigerant, clean the system

using the procedure described below.

1. Leak check system using procedure outlined on Page

12.

2. Evacuate the system using procedure outlined on

Page 13.

3. Use nitrogen to break the vacuum and install a new

filter drier in the system.

4. Evacuate the system again using procedure outlined

on Page 13.

5. Weigh in refrigerant using procedure outlined under

Start−Up and Charging Procedures.

6. Monitor the system to determine the amount of

moisture remaining in the oil. It may be necessary to

replace the filter drier several times to achieve the

required dryness level. If system dryness is not

verified, the compressor will fail in the future.

Unit Start−Up

IMPORTANT

If unit is equipped with a crankcase heater, it should be

energized 24 hours before unit start−up to prevent

compressor damage as a result of slugging.

1. Rotate fan to check for binding.

2. Inspect all factory− and field−installed wiring for loose

connections.

3. After evacuation is complete, open the liquid line and

suction line service valves to release the refrigerant

charge (contained in air conditioner) into the system.

4. Replace the stem caps and tighten to the value listed

in Table 1.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit’s

nameplate. If not, do not start the equipment until you

have consulted with the power company and the

voltage condition has been corrected.

6. Set the thermostat for a cooling demand. Turn on

power to the indoor handler and close the air

conditioner disconnect switch to start the unit.

7. Recheck voltage while the unit is running. Power must

be within range shown on the nameplate.

8. Check system for sufficient refrigerate using the

procedures that follow.

System Refrigerant

This section outlines procedures for:

1. Connecting gauge set for testing and charging;

2. Checking and adjusting indoor airflow;

3. Adding or removing refrigerant.

Loading...

Loading...