Page 31

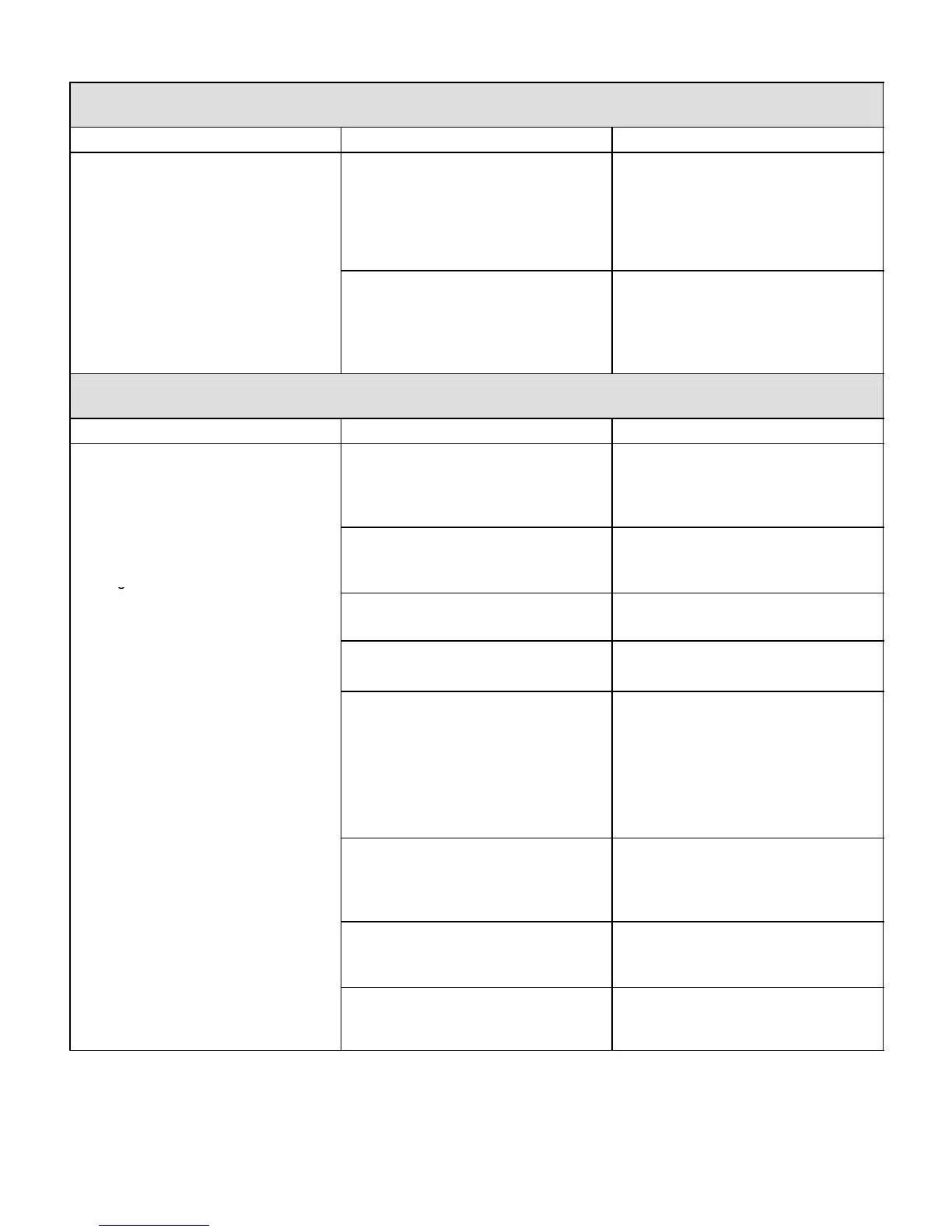

PROBLEM 2: UNIT FAILS TO FIRE IN THE HEATING MODE, COMBUSTION AIR INDUCER DOES

NOT ENERGIZE (CONT.).

Condition Possible Cause Corrective Action/Comments

2.3

− Unit operates with a cooling and con-

tinuous fan demand.

− Combustion air inducer will not start

with a Heating demand.

− Diagnostic lights flash the pressure

switch failure code 2 5 minutes after

2.3.1

Miswiring of furnace or improper con-

nections to combustion air inducer.

ACTION 1 − Check for correct wiring and loose

connections. Correct wiring and/or replace any

loose connections.

switch failure code 2.5 minutes after

heating demand.

LED#1−Off,

LED#2−Slow Flash

2.3.2

Combustion air inducer failure.

ACTION 1 − If there is 120V to combustion air in-

ducer and it does not operate, replace combus-

tion air inducer.

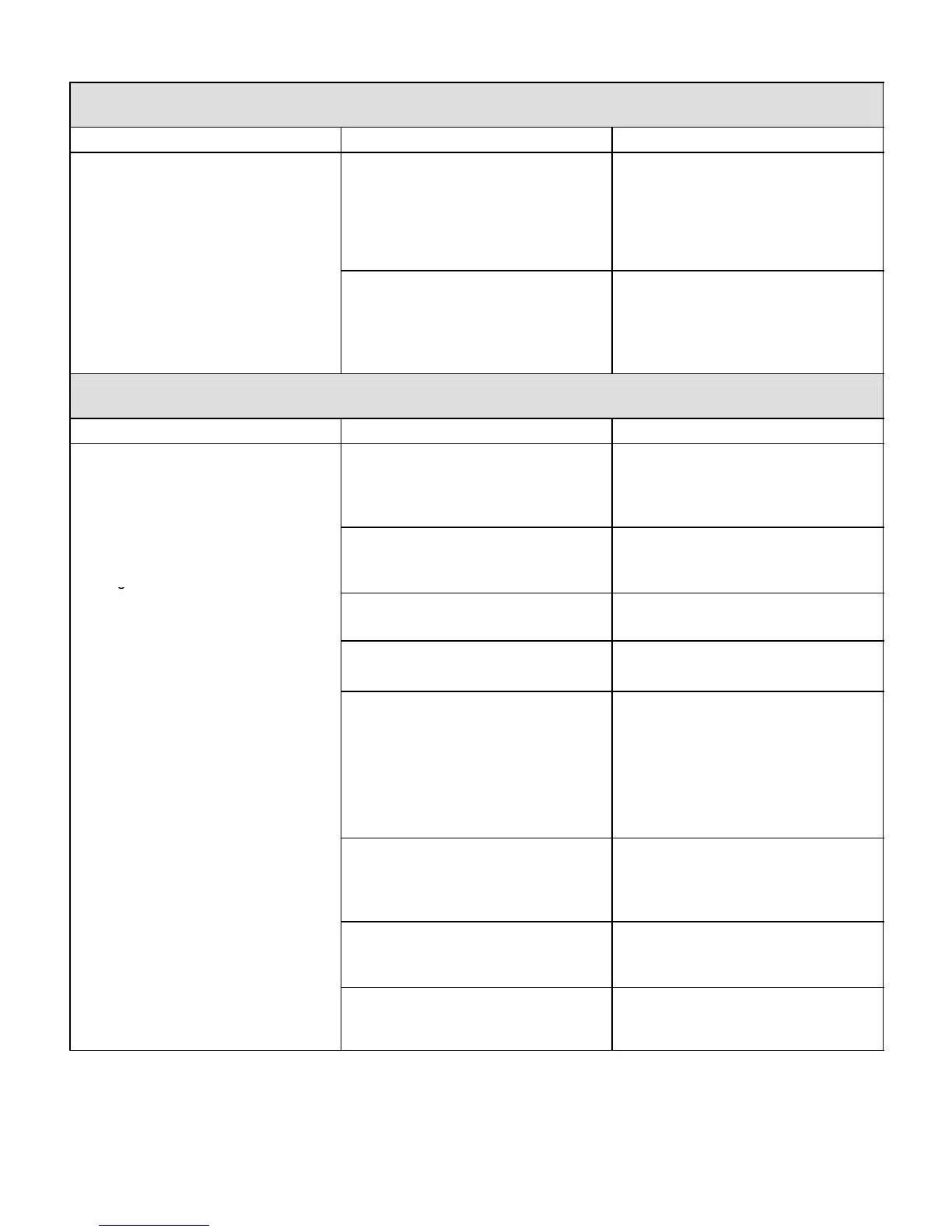

PROBLEM 3: UNIT FAILS TO FIRE IN THE HEATING MODE, COMBUSTION AIR BLOWER

ENERGIZES, IGNITOR IS NOT ENERGIZED.

Condition Possible Cause Corrective Action/Comments

3.1

− Unit operates with a cooling and

continuous fan demand.

− Combustion air inducer energizes

3.1.1

Pressure switch does not close due

to incorrect routing of the pressure

switch lines.

ACTION 1 − Check that the pressure switch lines

are correctly routed. Correctly route pressure

switch lines.

with a heating demand.

− Diagnostic lights flash the pressure

switch failure code 2.5 minutes after

heating demand.

3.1.2

Pressure switch does not close due

to obstructions in the pressure lines.

ACTION 1 − Remove any obstructions from the

the pressure lines and/or taps.

LED#1−Off

3.1.3

Pressure switch lines damaged

ACTION 1 − Check pressure switch lines for

leaks. Replace any broken lines.

LED#2−Slow Flash

3.1.4

Condensate in pressure switch line.

ACTION 1 − Check pressure switch lines for con-

densate. Remove condensate from lines. Check

that the condensate lines are located correctly.

3.1.5

Pressure switchdoes not close due to

a low differential pressure across the

pressure switch.

ACTION 1 − Check the differential pressure

across the pressure switch. This pressure

should exceed the set point listed on the

switch.

ACTION 2 − Check for restricted inlet vent. Re-

move all blockage.

ACTION 3 − Check for proper vent sizing and

run length. See installation instructions.

3.1.6

Wrong pressure switch installed in

the unit, or pressure switch is out of

calibration.

ACTION 1 − Check that the proper pressure

switch is installed in the unit. Replace pressure

switch if necessary.

3.1.7

Miswiring of furnace or improper con-

nections at pressure switch.

ACTION 1 − Check for correct wiring and loose

connections. Correct wiring and/or replace any

loose connections.

3.1.8

Pressure switch failure.

ACTION 1 − If all the above modes of failure have

been checked, the pressure switch may have

failed. Replace pressure switch and determine if

unit will operate.

Loading...

Loading...