507581-04 Page 55 of 60Issue 2128

6. If ame is not detected after rst ignition trial, the

ignition control will repeat steps 3 and 4 four more

times before locking out the gas valve. The ignition

control will then automatically repeat steps 1 through

6 after 60 minutes. To interrupt the 60 minute period,

move thermostat from “Heat” to “OFF” then back to

“Heat.” Heating sequence then restarts at step 1.

Gas Pressure Adjustment

Gas Flow (Approximate)

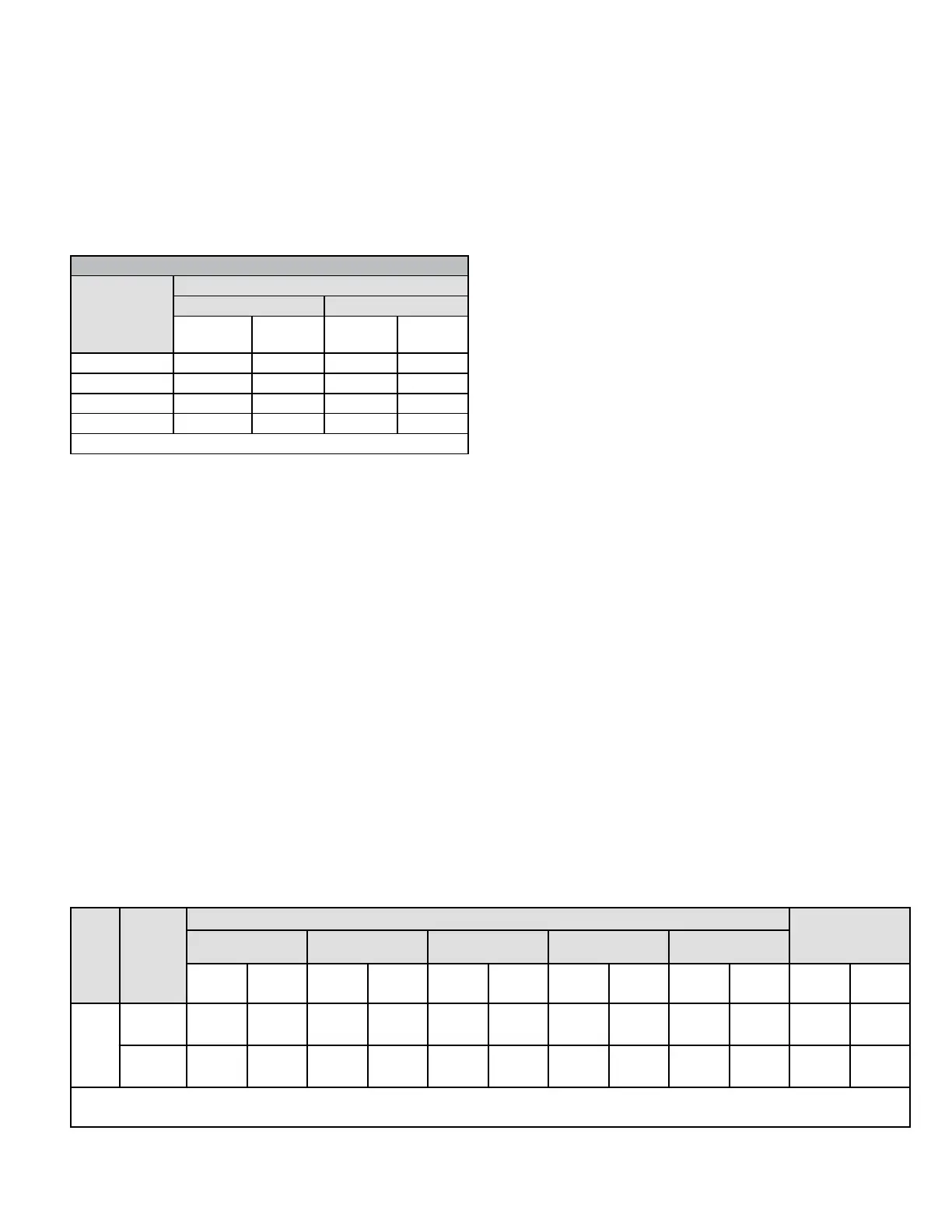

Table 14.

Gas Meter Clocking Chart

Model

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

-30 120 240 300 600

-45 80 160 200 400

-70 55 110 136 272

-110 33 66 82 164

Natural-1000 btu/cu ft LP-2500 btu/cu ft

Furnace should operate at least 5 minutes before checking

gas ow. Determine time in seconds for two revolutions of

gas through the meter. (Two revolutions assures a more

accurate time.) Divide by two and compare to time in Table

14. If manifold pressure matches Table 18 and rate is

incorrect, check gas orices for proper size and restriction.

Remove temporary gas meter if installed.

NOTE: To obtain accurate reading, shut off all other gas

appliances connected to meter.

Supply Pressure Measurement

An inlet pressure post on the inlet side of the gas valve

provides access to the supply pressure. See Figure 67.

Back out the 3/32 Hex screw one turn, connect a piece

of 5/16” tubing and connect to a manometer to measure

supply pressure.

NOTE: Shut unit off and remove manometer as soon as

an accurate reading has been obtained. Take care to re-

tighten the 3/32 Hex screw.

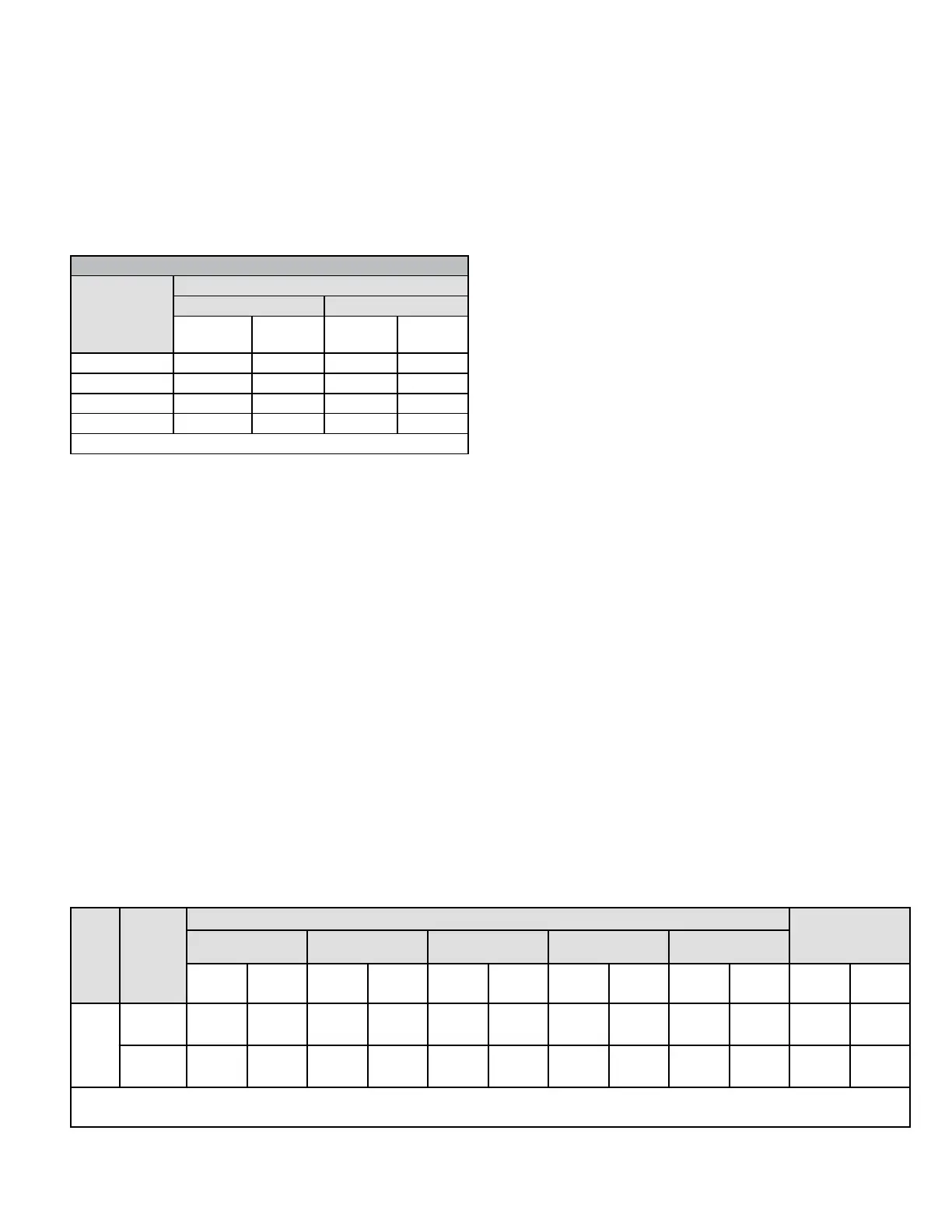

Unit Gas

Manifold Pressure in. w.g. Supply Line

Pressure in.

w.g. 0 - 10000 ft.

0 - 4500 ft. 4501 - 5500 ft. 5501 - 6500 ft. 6501 - 7500 ft. 7501 - 10000 ft.

Low

Fire

High

Fire

Low

Fire

High

Fire

Low

Fire

High

Fire

Low

Fire

High

Fire

Low

Fire

High

Fire

Min Max

All

Sizes

Natural 1.7 3.5 1.6 3.3 1.5 3.2 1.5 3.1 1.7 3.5 4.5 13.0

LP/

Propane

4.5 10.0 4.2 9.4 4.0 9.1 3.9 8.9 4.5 10.0 11.0 13.0

NOTE - A natural to L.P. propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit installation

instruction for the conversion procedure.

Table 18. Manifold and Supply Line Pressure 0 - 10,000 ft.

For proper furnace operation the minimum gas supply

pressure is 4.5” w.c and the maximum gas supply pressure

is 10.5” w.c for natural gas. The minimum gas supply

pressure is 10” w.c. and the maximum gas supply pressure

is 13” w.c. for LP/propane gas.

Manifold Pressure Measurement

1. A manifold pressure post located on the gas valve

provides access to the manifold pressure. See Figure

67. Back out the 3/32 Hex screw one turn, connect a

piece of 5/16” tubing and connect to a manometer to

measure supply pressure.

2. Start unit and allow 5 minutes for unit to reach steady

state.

3. While waiting for the unit to stabilize, observe the

ame. Flame should be stable and should not lift from

burner. Natural gas should burn blue.

4. After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

Table 18.

NOTE: Shut unit off and remove manometer as soon as

an accurate reading has been obtained. Take care to re-

tighten the 3/32 Hex screw.

Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking

combustion. Take combustion sample beyond the ue

outlet and compare to the tables below. The maximum

carbon monoxide reading should not exceed 100 ppm.

High Altitude Information

NOTE: In Canada, certication for installations at

elevations over 4500 feet (1371 m) is the jurisdiction of

local authorities.

Units may be installed at altitudes up to 10,000 ft. above

sea level. See Table 18 for de-rate manifold values. Units

installed at altitude of 7501 - 10,000 feet require an orice

change. Units installed at altitude of 4501 - 10,000 feet

(1371 to 3048 m) may require a pressure switch change

which can be ordered separately. Table 17 lists conversion

Loading...

Loading...