Do you have a question about the Lennox Allied Air A96UH2E and is the answer not in the manual?

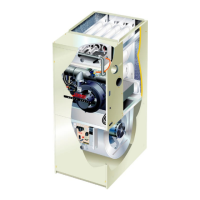

Details contents of the furnace packaging and instructions for checking damage.

Provides essential safety warnings, including CAUTION and WARNING statements for handling and installation.

Provides general guidance and recommendations for furnace installation, emphasizing compliance with local codes.

Describes an unconfined space and its air volume requirements for proper furnace operation.

Defines a confined space and its air volume requirements for proper furnace operation.

Provides instructions on furnace placement, leveling, and tilt for proper drainage.

Instructions for removing shipping bolts from the blower motor's flexible legs.

Guidelines for installing the furnace in an upflow configuration, including clearances.

Rules for connecting return air ducts, ensuring airtight seals and proper airflow.

Steps to remove the bottom panel for access or configuration changes.

Information and considerations for installing the furnace in horizontal positions.

Steps for constructing and installing the furnace on a platform in horizontal applications.

Guidance on suspending the furnace for horizontal installation in attics or crawl spaces.

Details requirements for the supply air plenum, including access panels for inspection.

Explains requirements for the return air plenum, emphasizing avoiding hazardous air sources.

Guidelines for supporting vent pipes to prevent vibration transmission and ensure proper installation.

Provides guidance on clearances and wall penetrations for vent pipe installations.

Instructions for safely removing a furnace from a common venting system and testing remaining appliances.

Provides guidelines for vent pipe sizing, routing, and termination, including direct and non-direct vent types.

Lists exhaust pipe size reductions needed for specific termination types and models.

Illustrates the installation of a non-direct vent roof termination kit.

Illustrates field-supplied wall termination for non-direct vent systems.

Shows extended wall termination requirements and supports for non-direct vent systems.

Illustrates using an existing chimney for non-direct vent applications.

Illustrates typical intake pipe connections for upflow direct/non-direct vent.

Illustrates typical intake pipe connections for horizontal direct/non-direct vent.

Shows intake pipe connections for upflow non-direct vent applications.

Shows intake pipe connections for horizontal non-direct vent applications.

Shows the location of the condensate trap and plugs on the furnace unit.

Illustrates condensate trap locations, including options for remote installation.

Depicts how the furnace and evaporator coil drains connect together for a common drain.

Illustrates common drain connection for evaporator coil and furnace.

Shows condensate trap with an optional overflow switch for safety.

Illustrates common drain connection for evaporator coil and furnace.

Illustrates common drain connection for evaporator coil and furnace.

Details trap and drain assembly configurations using different PVC pipe sizes.

Details the critical process of checking gas piping connections for leaks using a leak detection solution.

Warns about fire and explosion hazards and the importance of following safety procedures exactly.

Shows typical gas piping configurations for upflow installations.

Shows typical gas piping configurations for horizontal installations.

Provides precautions to protect electronic controls from electrostatic discharge during installation and service.

Outlines voltage, frequency, and waveform requirements when using a generator.

Guidelines for selecting thermostat location and making low voltage connections to the control board.

Diagram of the integrated control board, showing terminals and connections.

Explains how to set DIP switch 1 to select single-stage or two-stage thermostat operation.

Describes how to set the delay for second-stage heating activation based on thermostat type.

Details how to adjust the blower off delay for heating mode to optimize comfort and air temperature.

Explains how to adjust the blower off delay for cooling mode operation.

Describes how to set DIP switches for continuous fan operation and speed selection.

Illustrates wiring connections for various thermostat types and system configurations.

Illustrates wiring connections for various thermostat types and system configurations.

Illustrates wiring connections for various thermostat types and system configurations.

Illustrates wiring connections for various thermostat types and system configurations.

Provides air volume and wattage data for the 030B08 model at various blower speeds and static pressures.

Provides air volume and wattage data for the 045B12 model at various blower speeds and static pressures.

Provides air volume and wattage data for the 070B12 model at various blower speeds and static pressures.

Provides air volume and wattage data for the 090C16 model at various blower speeds and static pressures.

Provides air volume and wattage data for the 110C20 model at various blower speeds and static pressures.

Emphasizes reading safety information before attempting any operation or service.

Details the process of starting the furnace, including its automatic hot surface ignition system.

Instructions for safely operating the gas valve, including manual control and safety checks.

Provides steps to safely turn off the gas supply to the furnace for maintenance or emergencies.

Lists common issues and checks to perform if the furnace fails to operate correctly.

Describes the step-by-step process the furnace follows when calling for heat, from ignition to combustion.

Information on the primary limit control, its location, and factory settings.

Describes the location and manual reset function of the flame rollout switches.

Details the pressure switch function in verifying combustion air inducer operation.

Explains how to check and adjust blower speed to maintain proper temperature rise for efficient operation.

Information on the fan's ON time and adjustable OFF delay settings for comfort.

Guidance on setting the heat anticipator based on the unit's amp draw.

Steps for checking wiring, voltage, and amp draw on electrical components.

Instructions for winterizing the unit and caring for the condensate trap during periods of non-use.

Detailed procedures for cleaning the heat exchanger, including disassembly and reassembly.

Step-by-step instructions for cleaning the furnace burners and inspecting for blockages.

Lists available replacement cabinet components such as access panels and top cap.

Lists available replacement control panel components like transformer and integrated control board.

Lists available replacement blower parts including wheel, motor, and housing components.

Lists available replacement heating components like heat exchanger, gas manifold, and ignitor.

Outlines specific modifications to NFPA-54, Chapter 10, related to carbon monoxide detectors and signage.

Loading...

Loading...