Page 33

VIII−TYPICAL OPERATING CHARACTERISTICS

A−Blower Operation and Adjustment

NOTE− The following is a generalized procedure and

does not apply to all thermostat controls.

1− Blower operation is dependent on thermostat

control system.

2− Generally, blower operation is set at thermostat

subbase fan switch. With fan switch in ON position,

blower operates continuously. With fan switch in AUTO

position, blower cycles with demand.

3− In all cases, blower and entire unit will be off when the

system switch is in OFF position.

B−External Static Pressure

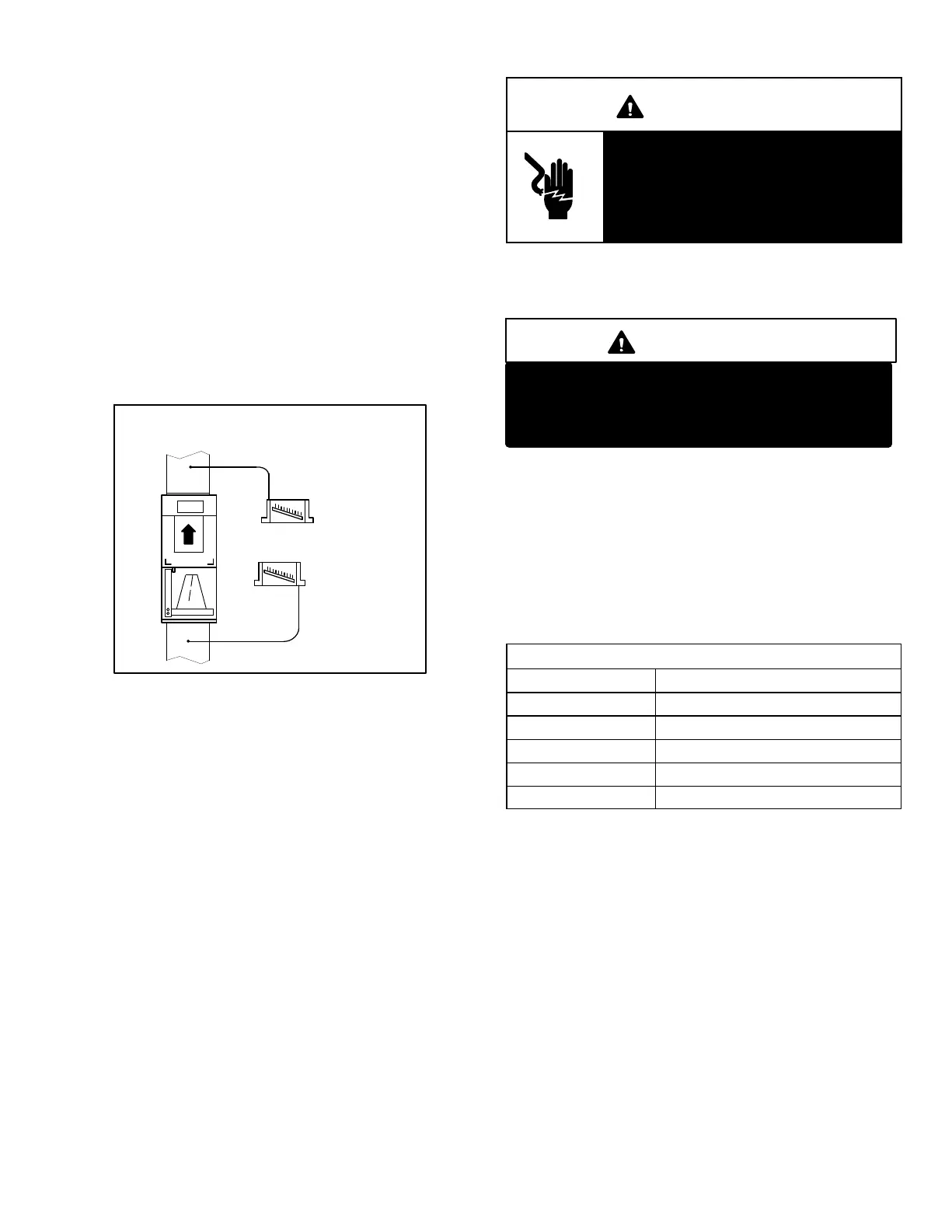

1. Measure tap locations as shown in figure 32.

FIGURE 32

STATIC PRESSURE TEST

MANOMETER

SUPPLY

RETURN

UNIT SHOWN IN

UPFLOW POSITION

+

_

2. Punch a 1/4" (6mm) diameter hole in supply and return

air plenums. Insert manometer hose flush with inside

edge of hole or insulation in the supply plenum only. Seal

around the hose with permagum. Connect the other end

of the hose to the zero end of the manometer. Leave the

other end of the manometer open to the atmosphere.

3. With only the blower motor running and the

evaporator coil dry, observe and take note of the

manometer reading.

4. Repeat step 2 for the return air plenum. Insert

manometer hose to the opposite end of the zero side

of the manometer. Leave the zero side of the

manometer open to atmosphere.

5. Repeat step 3.

6− Add the absolute values of the supply air reading and the

return air reading to get the external static pressure of the

unit. For example −.20 in.wg. on the return and +.30 in.wg.

on the supply result in external static pressure of .50 in.wg.

External static should not exceed .80" w.g. (200Pa)

Adjust blower motor speed to deliver the air desired

according to job requirements.

7− Seal around the holes when the check is complete.

IX−MAINTENANCE

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon-

nect switch(es). Unit may have multiple

power supplies.

At the beginning of each heating/cooling season, the

system should be checked as follows:

A−Filters

IMPORTANT

Filter access panel must be in place during unit

operation. Excessive warm air entering the unit

may result in water blow−off problems.

To remove filter, loosen the thumb screws holding the

filter panel in place. Slide filter out of the guides on either

side of cabinet, insert new filter and replace panel. Some

models come with a spacer so standard size filters can

be used. Filters should be inspected monthly and must

be replaced when dirty to ensure proper blower coil

operation. See table 15 for replacement filter sizes or

see the sticker located on the filter access door

specifying the size of the standard throw-away filter

which is used with the unit.

TABLE 15

CBX32MV FILTER SIZES

Unit Filter Size

CBX32MV018/024 15" X 20" (381mm X 508mm)

CBX32MV−024/030 20" X 20" (508mm X 508mm)

CBX32MV−036 20" X 22" (508mm X 599mm)

CBX32MV−048, −060 20" X 24" (508mm X 610mm)

CBX32MV−068 20" X 25" (508mm X 635mm)

B−Supply Air Blower

1- Check and clean blower wheel.

2- Motors are pre−lubricated for extended life; no further

lubrication is required.

C−Electrical

1- Check all wiring for loose connections.

2- Check circuit breaker located in unit control box.

3- Check for correct voltage at unit (unit operating).

4- Check amp-draw using a True root mean square

(RMS) amperage meter. Typical clamp−on ammeters

do not read current accurately.

5- Check to see that heat (if applicable) is operating.

D−Insulation

Outdoor piping insulation should be inspected yearly for

deterioration. If necessary, replace with same materials.

Loading...

Loading...