25

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Note: Remote receiver should be located in the

wall, or if installed in the control compartment,

pulled all the way forward and completely to the

left or right against the corner posts.

7. If wall-mounted ON/OFF control or thermo-

stat is to be used, mount it in a convenient

location on a wall near the fireplace.

8. If an optional control is to be used, wire it in

the low voltage circuit as shown in Figures

47 and 48.

Note: The supplied 15 feet of 2 conductor wire

has one end of each conductor connected to

the gas valve circuit and the other end of each

conductor placed loose inside the bottom

compartment.

9. If the optional control switch is installed,

turn the appliance-mounted ON/OFF burner

control switch to the OFF position.

10. After the wiring is complete, replace the

cover plate.

Note: The gas valve-mounted ON/OFF switch

is shown in Figures 47 and 48. It is integral

with the gas valve and should be set to the

ON position.

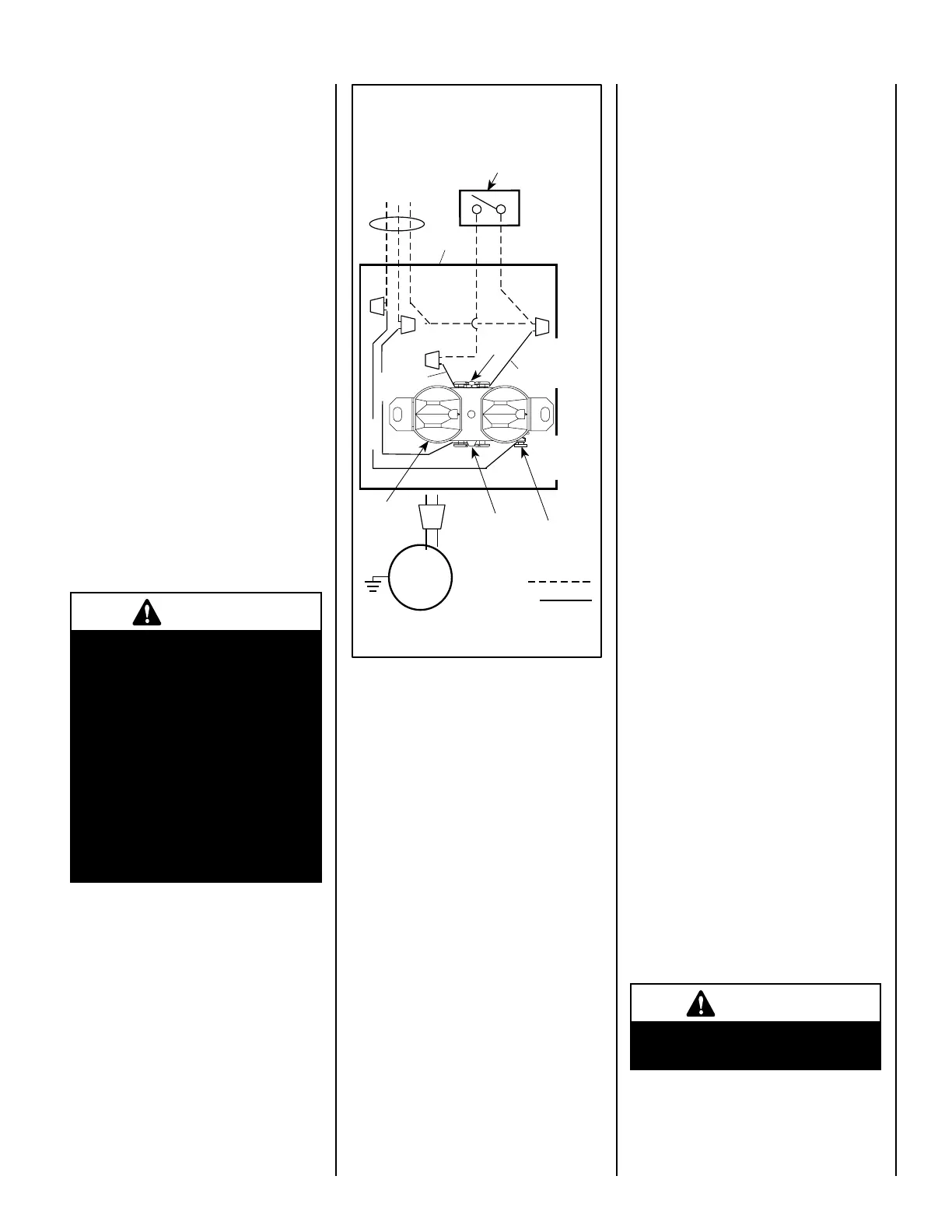

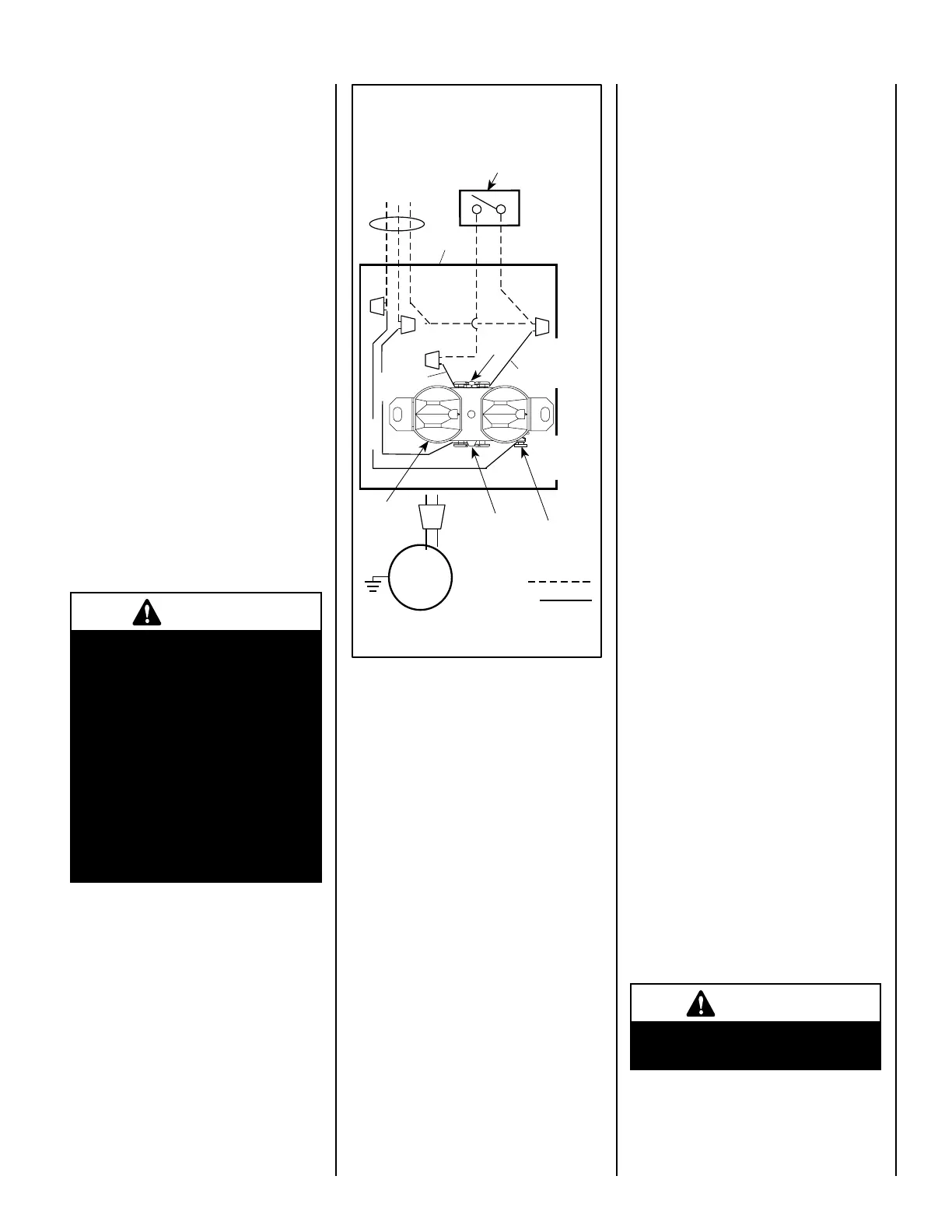

BLOWER CONTROL CIRCUIT WIRING

120V, 60HZ, 1PH

Factory Wired

Ground

Field Wired

Junction Box

Tab Intact

Tab

Broken

Plug blower

into this

receptacle

neerG - dnuorG

* Wall-mounted

ON/ OFF Blower

Switch or Variable

Speed Control Switch.

Blower

etihW - lar

t

ueN

120 VAC - Black

Green

Ground

Screw

White

Green

Neutral

Side of

Receptacle

Hot

Side of

Receptacle

Red

Black

Figure 49 - J-BOX WIRING

These appliances are equipped with a gas flex

line for use (where permitted) in connecting the

unit to the gas line. A gas flex line is provided to

aid in attaching the direct vent appliance to the

gas supply. The gas flex line can only be used

where local codes permit. Refer to Figure 50

for flex line description. The flex line is rated for

both natural and propane gas. A manual shut off

valve is also provided with the flex line.

The gas control valve is located in the lower

control compartment.

To access the valve open the lower control

compartment door (see Figure 51 ) by pushing

in the right top corner of the door. (The door

is hinged at the bottom.) Remove the bottom

compartment door by sliding the hinge pin,

located at the door’s left side, to the right until

it disengages from the left corner post hole.

Pull the door diagonally to the left, away from

the fireplace.

Remove the modesty panel. To remove the

modesty panel, slide the panel forward until

it contacts the cabinet bottom panel, then lift

straight up and tilt forward.

Remove the modesty panel carefully, so that

none of the wires become loose or discon-

nected.

The millivolt control valve has a 3/8"

(10 mm) NPT thread inlet port. The electronic

control valve has a 1/2" (13 mm) NPT thread

inlet port and is fitted with a 1/2" x 3/8" (13 mm x

10 mm) NPT fitting.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure propane

resistant compounds are used in propane

applications).

All codes require a shut-off valve mounted

in the supply line. The orientation of the

shut-off valve should face the front. Figure

50 illustrates two methods for connecting the

gas supply. A sediment Trap is recommended

to prevent moisture and debris in the gas line

for damaging the valve.

WARNING

Electronic models of these appli-

ances are equipped with a three-

prong (grounding) plug utilized

in connecting the electronic

components to the junction box

in the lower compartment. This

grounding plug provides protec-

tion against shock hazard and

should be plugged directly into

the properly grounded three-

prong receptacle. DO NOT cut

or remove the grounding prong

from the plug.

FBK-250 Blower Kit

(See Figure 48 on page 24)-

An electrical outlet box is provided for the

installation of the FBK-250 forced air blower

kit. Electrical power must be provided to this

box to operate these blowers. Install the blower

kit according to the installation instructions

provided with the kit.

Note: The tab connecting the receptacles of the

outlet box must be broken in FBK-100 and FBK-

200 blower kit applications. See Figure 49.

Step 7. CONNECTING GAS LINE

Make gas line connections. All codes require a

shut-off valve mounted in the supply line. Figure

50 illustrates two methods for connecting the

gas supply. The flex-line method is acceptable

in the U.S., however, Canadian requirements

vary depending on locality. Installation must

be in compliance with local codes. A sediment

trap is recommended in the gas piping within

the home to prevent moisture and debris in the

line from damaging the valve.

Step 6. WIRING - OPTIONAL FORCED AIR

BLOWER KIT

FBK-100 and FBK-200 Kits

(See Figure 47 on page 24) -

An electrical outlet box is provided for the

installation of the FBK-100, FBK-200 forced air

blower kits. Electrical power must be provided

to this box to operate these blowers. Install the

blower kits according to the installation instruc-

tions provided with the kits.

WARNING

Never use an open flame to

check for leaks.

TEST ALL CONNECTIONS FOR GAS LEAKS

(FACTORY AND FIELD):

Loading...

Loading...