Page 31

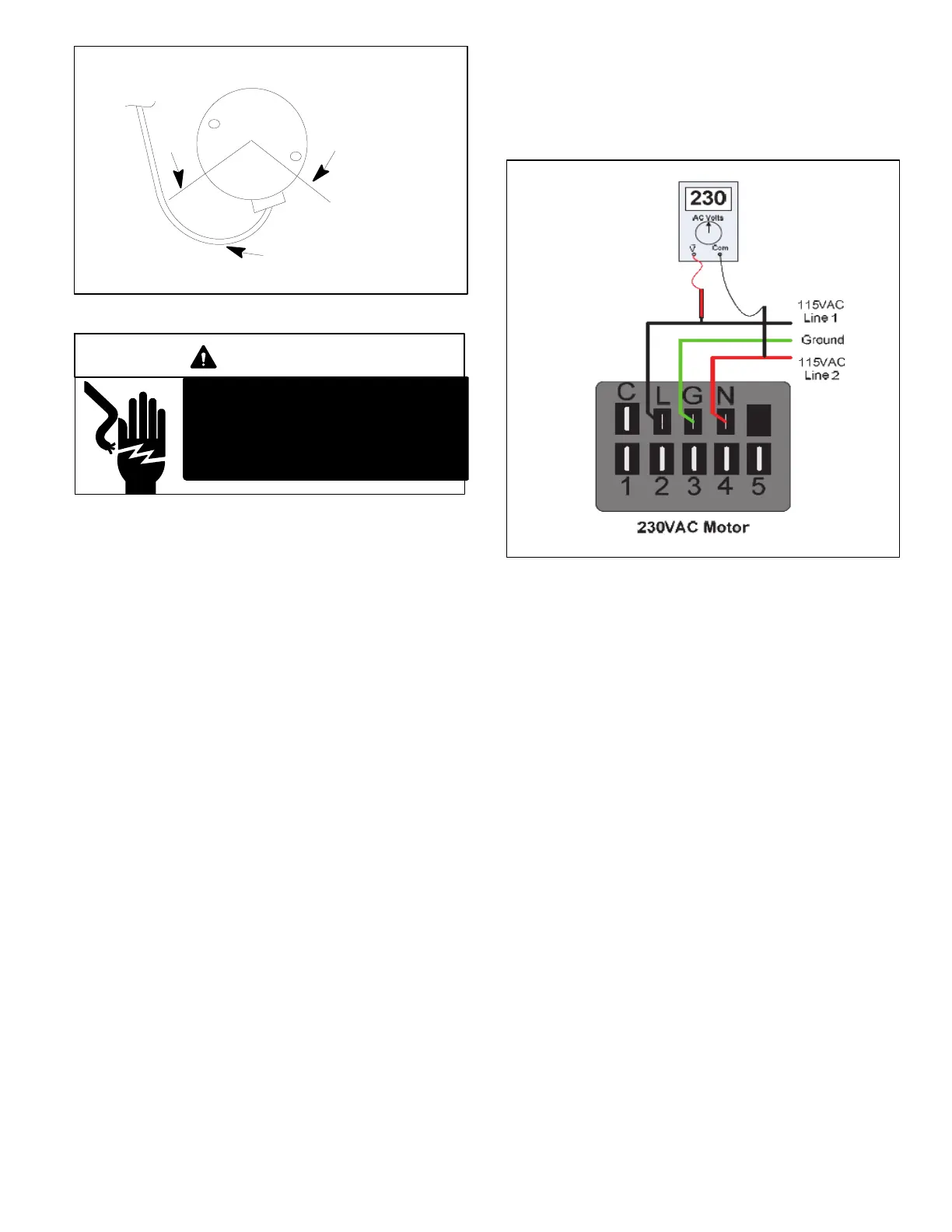

DRIP LOOP

BACK OF

UNIT

CONNECTOR

ORIENTATION (BETWEEN

4 AND 8 O'CLOCK)

DRIP LOOP

FIGURE 16

DANGER

Disconnect power from unit and wait

at least five minutes to allow capaci

tors to discharge before attempting to

service motor. Failure to wait may

cause personal injury or death.

INDOOR BLOWER MOTOR (B3) CONTROL TROU

BLESHOOTING (REGAL-BELOIT)

Before troubleshooting any HVAC system, it is a good prac

tice to become familiar with the components and wiring dia

gram. On fan motor systems it is a good practice to check

the tap selections and delay settings.

If the motor is running but the system is noisy, shutting

down on its limits or safeties or the evaporator coil is freez

ing, there is a good chance the motor is good. The problem

is most likely external to the motor.

Check the tap selections using the HVAC OEM guide

Check the air distribution system components for dirt

load and closed dampers, registers and grilles.

Measure the total external static pressure. Make re

pair(s) if above the recommended maximum level and con

firm airflow at the new total ESP with the air flow tables (be

ginning on page 4). Aftermarket filter sizing is a common

issue.

If the motor is not running, the following checks will dia

gnose whether it is operational. Always disconnect the

power to the HVAC system before disconnecting or re

connecting any connectors to these motors. There are

two inputs needed to operate this motor, a high voltage con

stant power source, and the low voltage communication

that selects the torque value in each tap per demand.

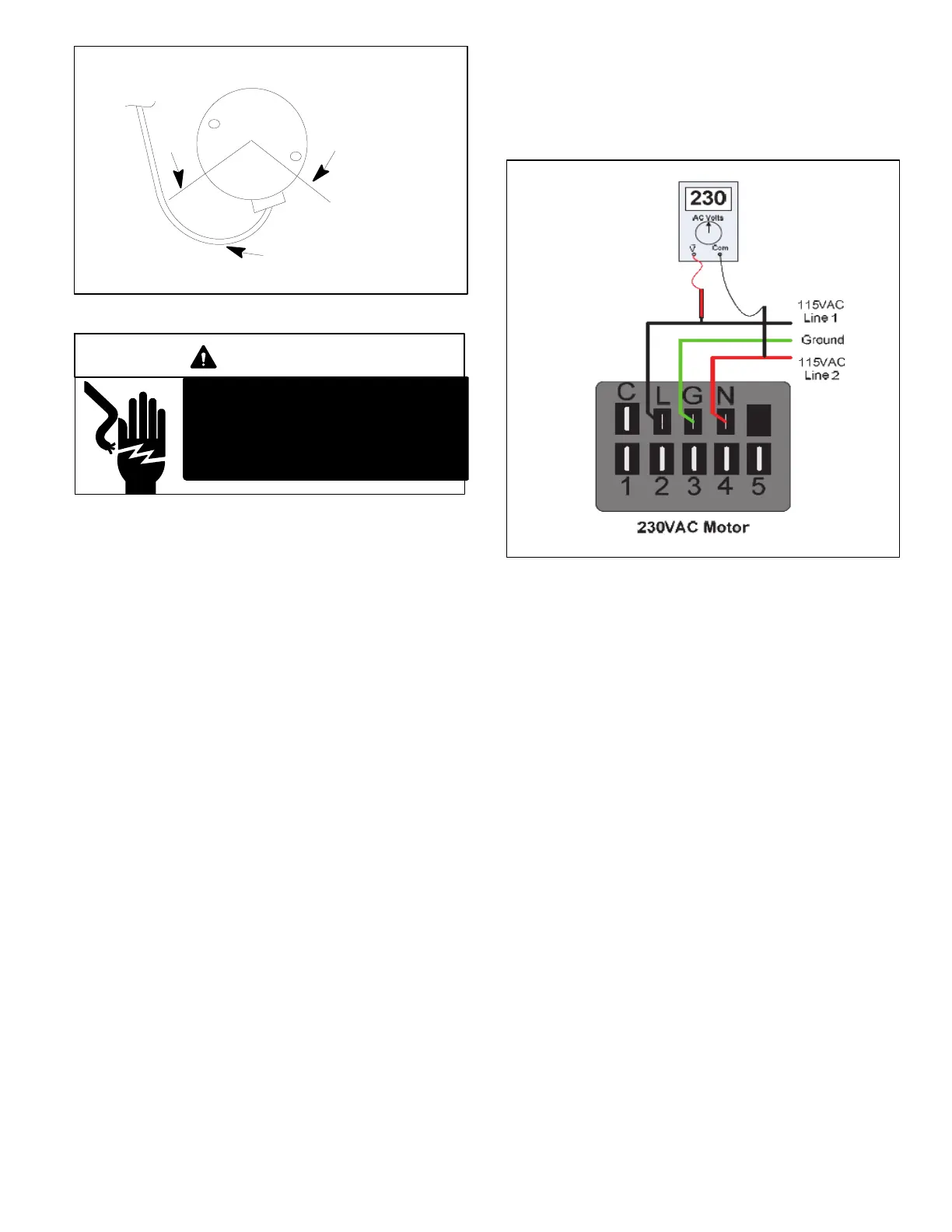

Checking 230VAC Voltage Input

First check the high voltage to terminals (L) and (N). There

should be 230VAC on these two terminals whenever there

is power to the system, regardless of a demand call. Apply

ing incorrect high voltage to the motor may cause the motor

to not operate, or even damage the motor.

230VAC

VOLTAGE

FIGURE 17

Checking the Low-Voltage Communication Input

If no low voltage communication (typically 24VAC) is meas

ured at the motor on taps 1-5, check the HVAC system wir

ing, controls and demand call. Always check low voltage

between terminals 1-5 and (C) at the motor, never ground.

Once the problem is corrected, confirm that the low voltage

communication is applied to a programmed tap. If proper

low voltage communication is present at a programmed

tap, with proper high voltage to the motor and it still does not

operate, the motor is failed.

1- Initiate a demand from the thermostat and check the

voltage between the common and the appropriate mo

tor terminal 1- 5. Confirm the meter is set to the 24VAC.

2- If the low voltage communication is not present, check

the demand from the thermostat. Also check the output

terminal and wires from the K20 blower relay.

3- If the motor has proper high voltage as identified in the

previous section, and proper low voltage to a pro

grammed terminal, and motor is not operating, the mo

tor has failed. Replace motor.

Loading...

Loading...