IOM / ROOF-TOP FLEXY™ Series - Page 79

PLANNING DE MAINTENANCEPLANNING DE MAINTENANCE

PLANNING DE MAINTENANCEPLANNING DE MAINTENANCE

PLANNING DE MAINTENANCE

ELECTRICAL TERMINALS

At least once a year:

- Power down the machine, blow away any dust

from inside the unit, and check and tighten if

necessary the connections.

- Power up the machine, test the safety

mechanisms.

- An analysis of the terminal in operating mode can

throw light on any strange noises from the

contactors or other units. Foreign bodies can

disrupt the operation of the components and

causes noisy vibration.

To avoid accidents, remember that this type of

maintenance requires electrical expertise.

REFRIGERATION CIRCUITS

At least once a year, carry out an in-depth inspection

of the refrigerant circuits.

In addition, before each season (or every 3 months if

used permanently) the controls listed in the

maintenance contract must be performed, i.e. check

the refrigerant change, evaporation and condensing

temperatures etc...

This work must be carried out by a trained refrigeration

engineer. We shall therefore keep the details of the

work and the type of checks to be performed to a

minimum.

IN ACCORDANCE WITH THE LAW

REFRIGERATION FLUIDS MUST BE COLLECTED

DEGASSING INTO THE ATMOSPHERE IS

FORBIDDEN.

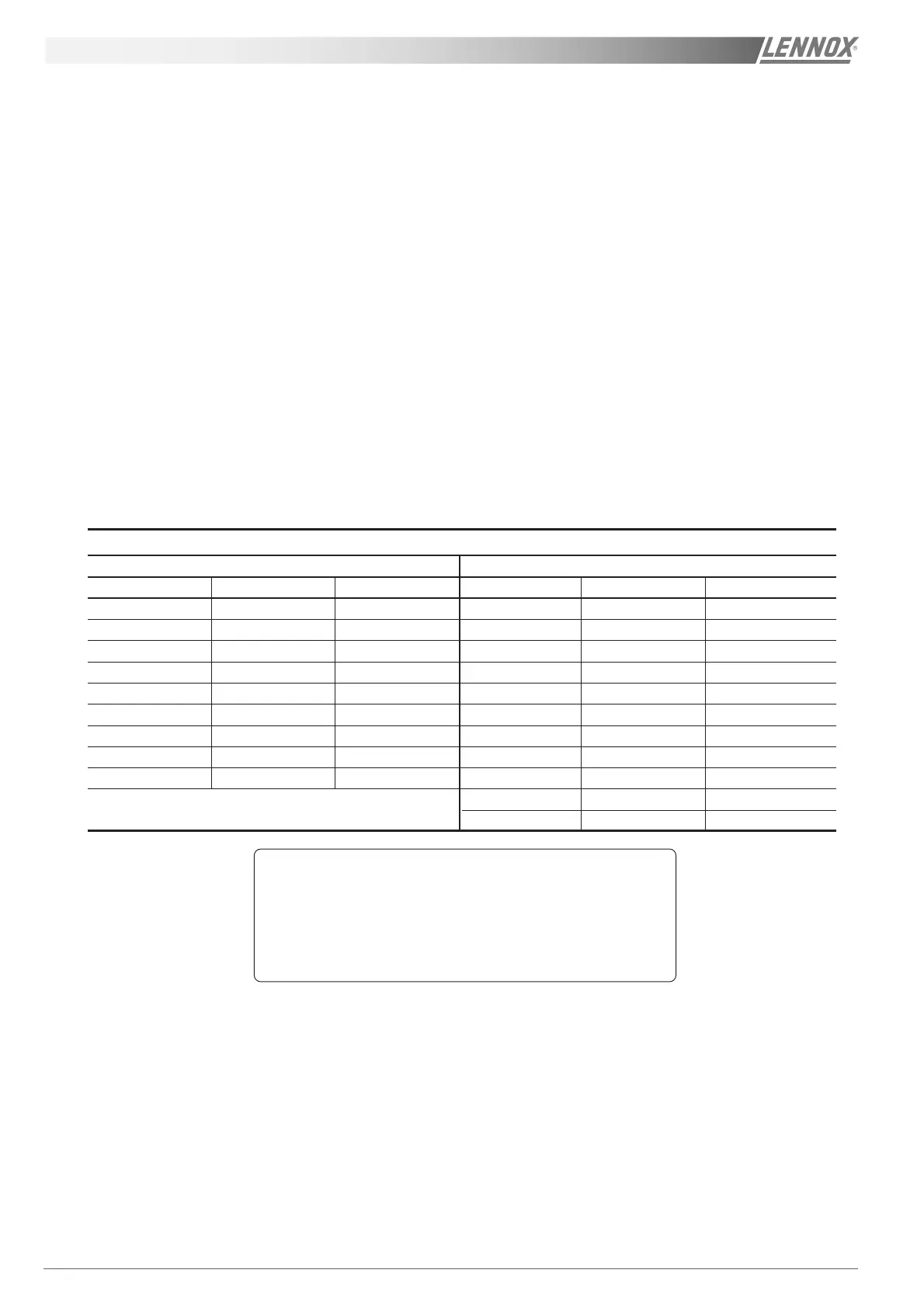

REFRIGERANT CHARGES valid for R407c and R22

Gamme FC/FH/FG/FD Gamme FX

Size Nbr of circuits kg Size Nbr of circuits kg

50 1925 22 x 4

60 2 7 + 7 30 22 x 4

70 2 8,5 + 8,5 35 22 x 5

85 2 13 + 13 40 22 x 6

100 2 13 + 13 55 22 x 6

120 2 + 1 ( 8 + 7,5 ) + 11 70 2 2 x 10

140 2 + 1 (9 + 9) + 11 85 2 2 x 11

160 4 4 x 11 100 2 2 x 12

190 4 4 x 11 110 44 x 7

140 4 4 x 7,5

170 4 4 x 8,5

Loading...

Loading...