Page 23

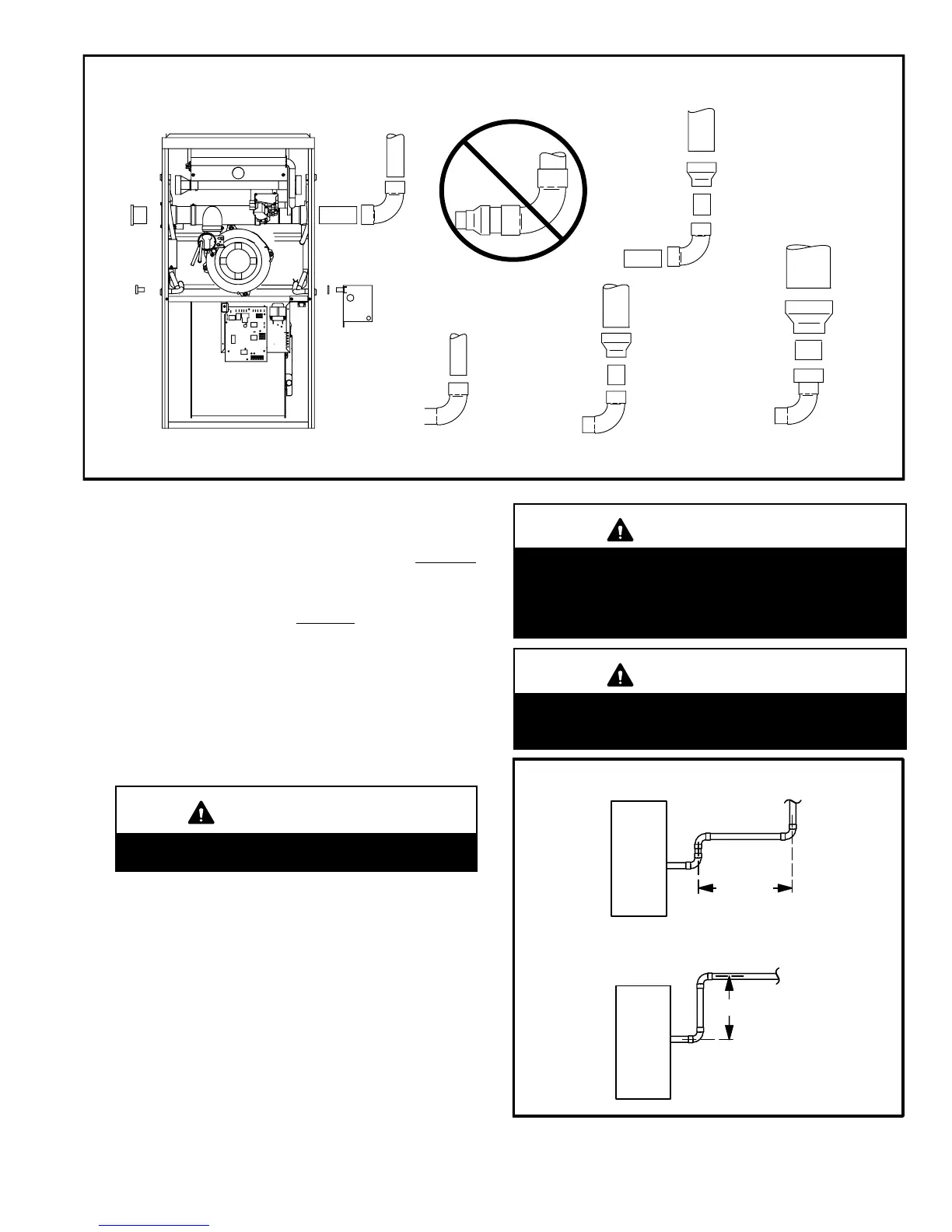

FIGURE 19

TYPICAL EXHAUST PIPE CONNECTIONS AND CONDENSATE TRAP INSTALLATION

IN UPFLOW DIRECT OR NON-DIRECT VENT APPLICATIONS

(Right-Hand Exit)

CONDENSATE

TRAP

(Must be installed

on same side as

exhaust piping)

VENT PLUG

(Must be

glued in

place)

PLUG

*2" diameter street elbow provided.

**3" diameter reducing elbow provided.

2”

2”

2”

2”

2”

2−1/2",

3", OR

4"

G43UF−045, 070

or 090 with

2−1/2", 3", or 4"

vent pipe

G43UF−135 with

3" OR 4" vent pipe

3"**

3"

REDUCER

(use only if

4" pipe is

required)

4"

2”

G43UF−110−1, −2, −3 with

2−1/2", 3", OR 4" vent pipe

2"*

2"***

TRANSITION

2−1/2",

3", OR

4"

***Limit pipe length to 2".

G43UF-1 10 with

2” vent pipe

2”*

TRANSITION

Exhaust Piping

NOTE − A 2" diameter street ell is strapped to the blower

deck of 48C−110 and 60C−110 units. Street ell must be

glued directly into the unit flue collar. See figure 19. A 3" to

2" reducing ell is strapped to the blower deck of the

60D−135 units. The reducing ell must be

glued directly into

the unit flue collar.

1. Choose the appropriate side for venting. Glue the

field−provided exhaust vent pipe (or provided street

ell) to the flue collar. All cement joints should be made

according to the specifications outlined in ASTM D

2855. Refer to pipe and fittings specifications and glu-

ing procedures.

IMPORTANT

Exhaust piping and condensate trap must be

installed on the same side of the unit.

2. All horizontal runs of exhaust pipe must slope back to-

ward unit. A minimum of 1/4" (6mm) drop for each 12"

(305mm) of horizontal run is mandatory for drainage.

Horizontal runs of exhaust piping must be supported ev-

ery 5 feet (1.52m) using hangers.

NOTE − Exhaust piping should be checked carefully to

make sure there are no sags or low spots.

3. On the opposite side of the cabinet, glue the provided

2" vent plug into the unused flue collar.

4. Route piping to outside of structure. Continue with

installation following instructions given in piping ter-

mination section.

CAUTION

Do not discharge exhaust into an existing stack or

stack that also serves another gas appliance. If verti-

cal discharge through an existing unused stack is re-

quired, insert PVC pipe inside the stack until the end

is even with the top or outlet end of the metal stack.

CAUTION

The exhaust vent pipe operates under positive pres-

sure and must be completely sealed to prevent leak-

age of combustion products into the living space.

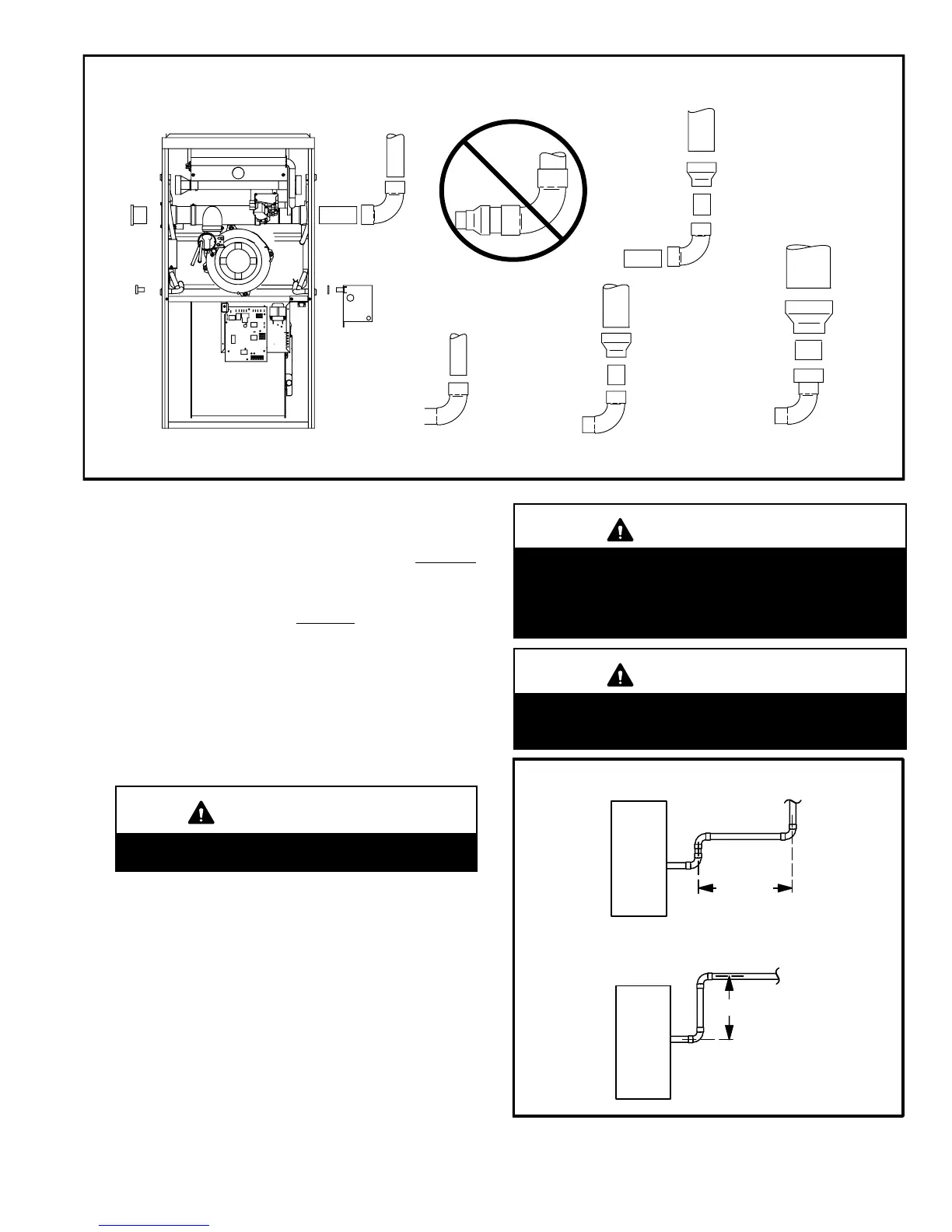

FIGURE 20

Exhaust Pipe Offset

12" Min.

12" Min.

Upflow Application

Rooftop Termination

Upflow Application

Side Wall Termination

Loading...

Loading...