Page 54

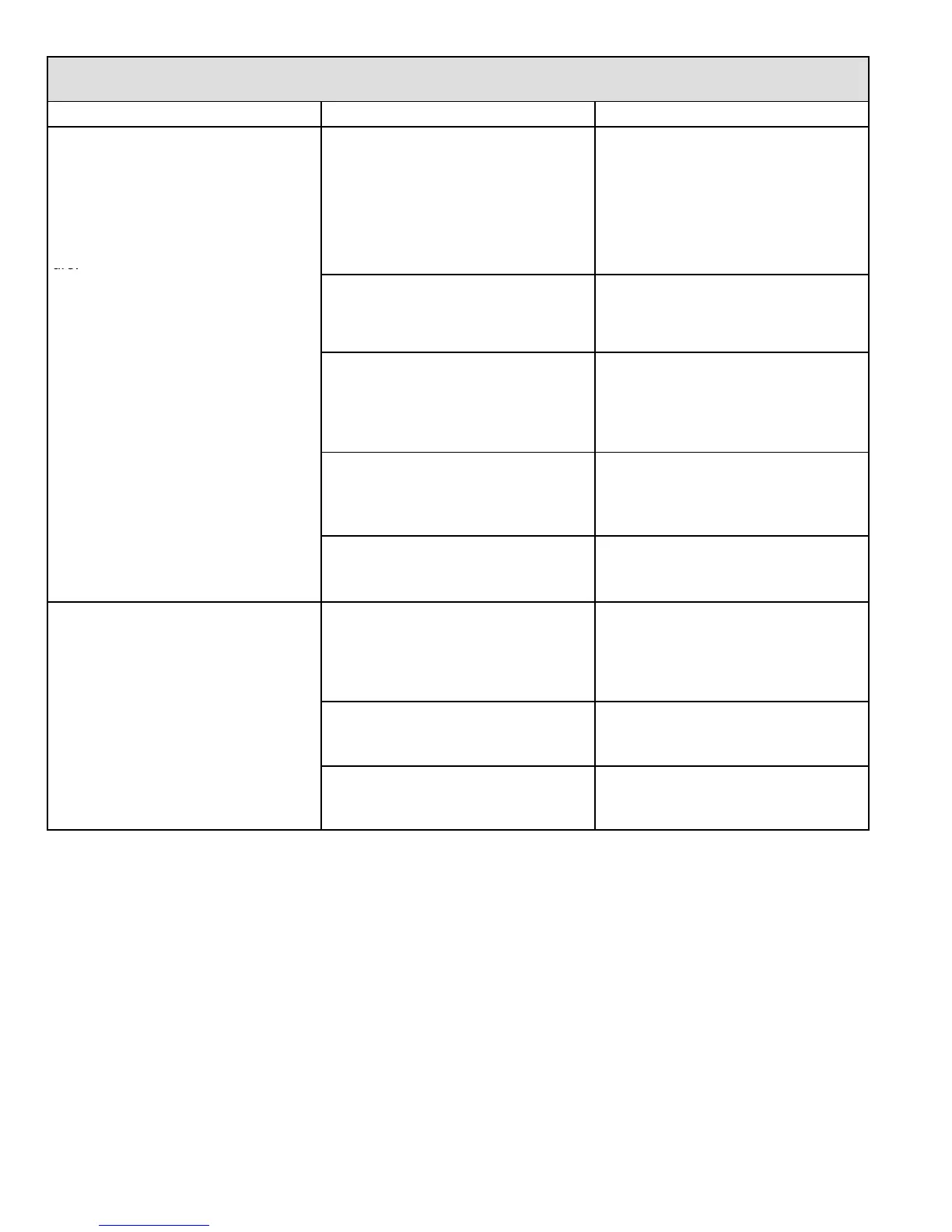

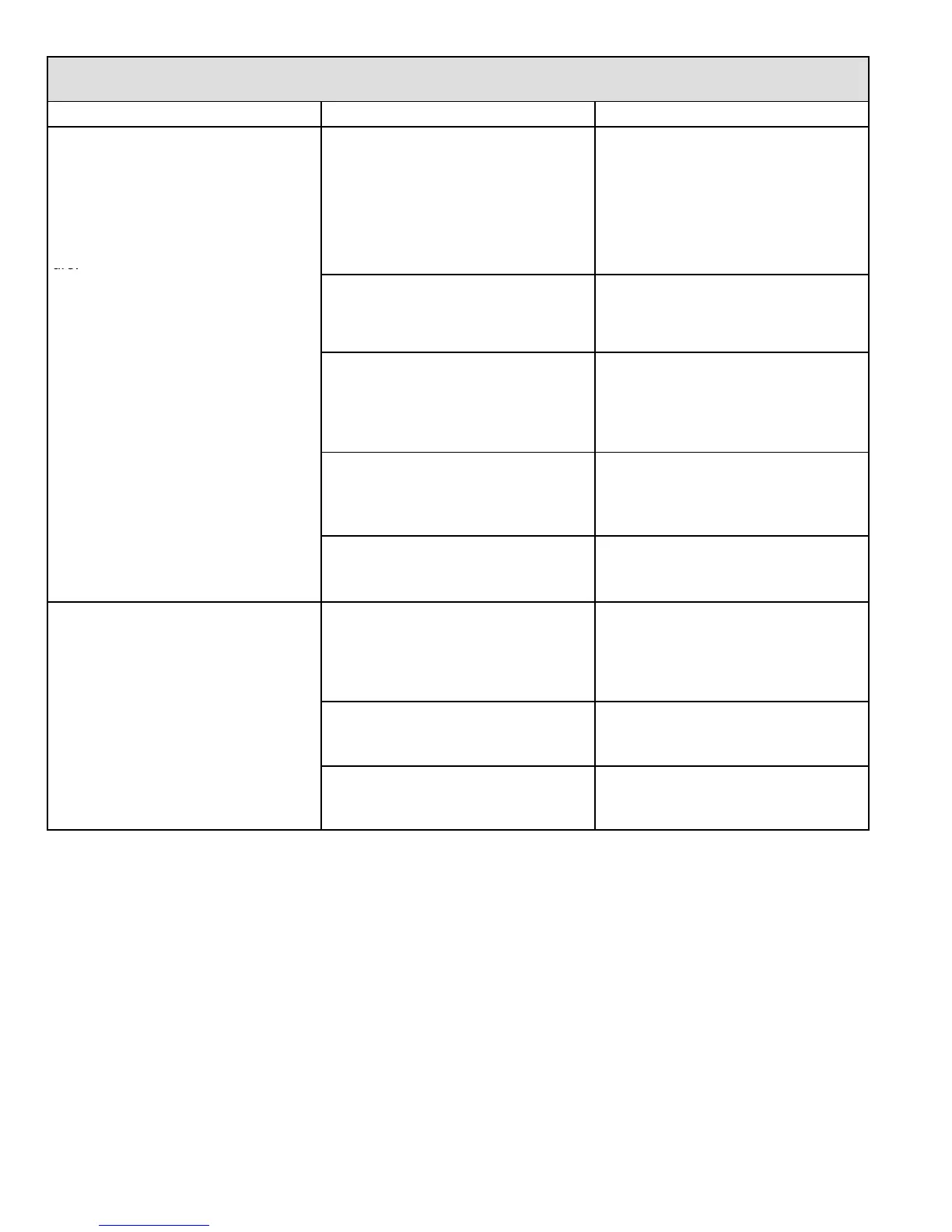

PROBLEM 5: BURNERS LIGHT WITH HEATING DEMAND BUT UNIT SHUTS DOWN

PREMATURELY (CONT.)

Condition Possible Cause Corrective Action/Comments

5.3

− Combustion air inducer energizes

with a heating demand.

− Burners light.

− Roll−out switch trips during the

heating demand.

− Diagnostic lights flash roll−out fail-

ure.

5.3.1

Unit is firing above 100% of the

nameplate input.

ACTION 1 − Check that the manifold pressure

matches value listed on nameplate. See installa-

tion instructions for proper procedure.

ACTION 2 − Verify that the installed orifice size

match the size listed on the nameplate or installa-

tion instructions.

ACTION 3 − Check gas valve sensing hose to in-

sure no leaks are present.

ACTION 4 − Check the input rate to verify rate

matches value listed on nameplate.

LED#1−On

LED#2−Slow Flash

5.3.2

Gas orifices leak at the manifold con-

nection.

ACTION 1 − Tighten orifice until leak is sealed.

NOTE: Be careful not to strip orifice threads.

ACTION 2 − Check for gas leakage at the

threaded orifice connection. Use approved meth-

od for leak detection (see unit instructions).

5.3.3

Air leakage at the connections be-

tween the primary heat exchanger,

secondary heat exchanger, and com-

bustion air blower.

ACTION 1 − Check for air leakage at all joints in

the heat exchanger assembly. Condition will

cause high CO2 with high CO.

ACTION 2 − Seal leakage if possible, replace

heat exchanger if necessary, tag and return heat

exchanger to proper Lennox personnel.

5.3.4

Insufficient flow through the heat ex-

changer caused by a sooted or re-

stricted heat exchanger.

ACTION 1 − Check for sooting deposits or other

restrictions in the heat exchanger assembly.

Clean assembly as outlined in instruction manu-

al.

ACTION 2 − Check for proper combustion.

5.3.5

Burners are not properly located in

the burner box.

ACTION 1 − Check that the burners are firing into

the center of the heat exchanger openings. Cor-

rect the location of the burners if necessary.

5.4

− Combustion air inducer energizes

with a heating demand.

− Burners light roughly and the unit

fails to stay lit.

5.4.1

Recirculation of flue gases. This con-

dition causes rough ignitions and op-

eration. Problem is characterized by

nuisance flame failures.

ACTION 1 − Check for proper flow of exhaust

gases away from intake vent. Remove any ob-

stacles in front of the intake and exhaust vent

which would cause recirculation.

ACTION 2 − Check for correct intake and exhaust

vent installation. See instructions

− Diagnostic lights flash watchguard

flame failure.

5.4.2

Improper burner cross−overs

ACTION 1 − Remove burner and inspect the

cross−overs for burrs, or any restriction or if

crossover is warped. Remove restriction or re-

place burners.

LED#1−Alternating Slow Flash

LED#2−Alternating Slow Flash

5.4.3

Prove Switch opens 5 times during a

single demand

ACTION 1 − Inspect vent pipe installation and for

any restriction. Remove restriction.

ACTION 2 − Check prove switch reliability.

Loading...

Loading...