Page 11

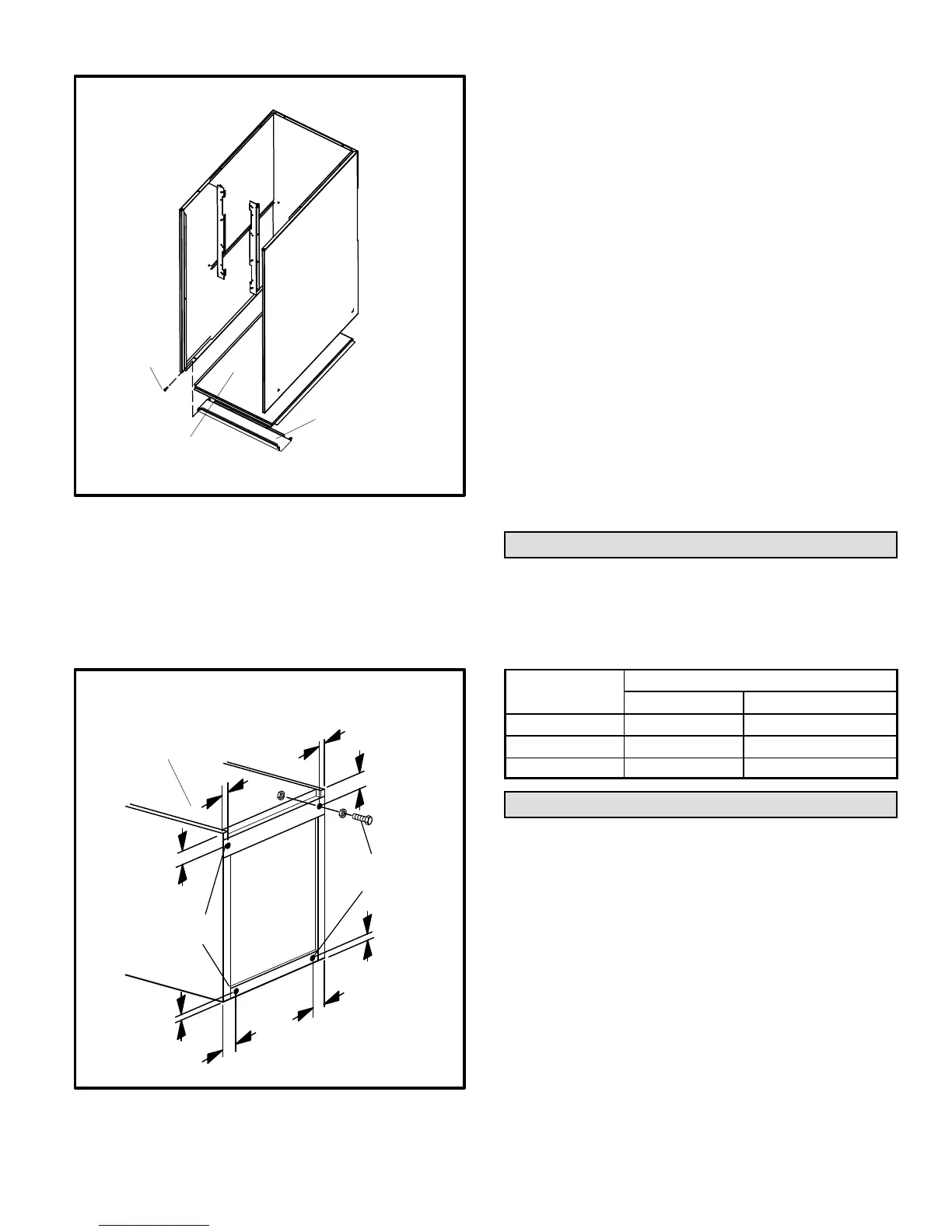

Removing the Bottom Panel

FIGURE 11

Screw

Bottom Panel

Bottom Cap

Removing the Bottom Panel

Remove the two screws that secure the bottom cap to the

furnace. Pivot the bottom cap down to release the bottom

panel. Once the bottom panel has been removed, reinstall

the bottom cap. See figure 11.

FIGURE 12

1−3/4

(44)

1−3/4

(44)

3/8

(10)

1−3/4 (44)

3/8

(10)

3/8

(10)

3/8

(10)

1−3/4

(44)

Leveling Bolt Installation

Leveling Bolt

Locations

Leveling Bolt

Locations

Inches (mm)

Furnace Front

Furnace

Bottom

Leveling an Upflow Unit

When the side return air inlets are used in an upflow ap-

plication, it may be necessary to install leveling bolts on the

bottom of the furnace. Use field−supplied corrosion−resist-

ant 5/16 inch machine bolts (4) and nuts (8). See figure 12.

NOTE − The maximum length of the bolt is 1−1/2 inches.

1 − Lay the furnace on its back and drill a 5/16 inch diame-

ter hole in each corner of the furnace’s bottom. See fig-

ure 12 for the correct location of the holes. Drill through

the bottom panel and the bottom flange of the cabinet.

2 − Install one bolt and two nuts into each hole. Screw the

first nut onto a bolt and then insert the bolt into a hole. A

flat washer may be added between the nut and the bot-

tom of the unit.

3 − Screw another nut onto the bolt on the inside of the fur-

nace base. A flat washer may be added between the

nut and the bottom of the unit.

4 − Adjust the outside nut to the appropriate height and

tighten the inside nut to secure the arrangement.

NOTE − The unit may be tilted back−to−front a maximum of

1/2". This will ensure proper draining of the heat exchang-

er.

Filters

This unit is not equipped with a filter or rack. A field−pro-

vided filter is required for the unit to operate properly. Table

1 lists recommended filter sizes.

A filter must be in place whenever the unit is operating.

TABLE 1

Furnace

Cabinet Width

Filter Size

Side Return Bottom Return

17−1/2" 16 X 25 X 1 (1) 16 X 25 X 1 (1)

21" 16 X 25 X 1 (1) 20 X 25 X 1 (1)

24−1/2" 16 X 25 X 1 (2) 24 X 25 X 1 (1)

Duct System

Use industry-approved standards to size and install the

supply and return air duct system. This will result in a quiet

and low-static system that has uniform air distribution.

NOTE − Operation of this furnace in heating mode (indoor

blower operating at selected heating speed) with an exter-

nal static pressure which exceeds 0.5 inches w.c. may re-

sult in erratic limit operation.

Supply Air Plenum

If the furnace is installed without a cooling coil, a removable

access panel should be installed in the supply air duct. The

access panel should be large enough to permit inspection

(by reflected light) of the heat exchanger for leaks after the

furnace is installed. The furnace access panel must always

be in place when the furnace is operating and it must not

allow leaks into the supply air duct system.

Loading...

Loading...