Page 28

4 − Piping should be sloped 1/4 inch per 15 feet (6mm per

5.6m) upward toward the gas meter from the furnace.

The piping must be supported at proper intervals, ev-

ery 8 to 10 feet (2.44 to 3.05m), using suitable hangers

or straps. Install a drip leg in vertical pipe runs to serve as

a trap for sediment or condensate.

5 − A 1/8" N.P.T. plugged tap or pressure post is located

on the gas valve to facilitate test gauge connection.

See figures 45 and 46.

6 − In some localities, codes may require installation of a

manual main shut-off valve and union (furnished by in-

staller) external to the unit. Union must be of the

ground joint type.

IMPORTANT

Compounds used on threaded joints of gas piping

must be resistant to the actions of liquified petro-

leum gases.

FIGURE 37

MANUAL MAIN SHUT−OFF

VALVE WILL NOT HOLD

NORMAL TEST PRESSURE

CAP

FURNACE

ISOLATE

GAS VALVE

Leak Check

After gas piping is completed, carefully check all piping

connections (factory− and field−installed) for gas leaks. Use

a leak detecting solution or other preferred means.

The furnace must be isolated from the gas supply system

by closing its individual manual shut-off valve during any

pressure testing of the gas supply system at pressures less

than or equal to 1/2 psig (3.48 kPa, 14 inches w.c.).

IMPORTANT

When testing pressure of gas lines, gas valve must

be disconnected and isolated. See figure 37. Gas

valves can be damaged if subjected to pressures

greater than 1/2 psig (3.48 kPa).

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could

result in serious injury, death, or property damage.

Never use an open flame to test for gas leaks. Check

all connections using a commercially available soap

solution made specifically for leak detection.Some

soaps used for leak detection are corrosive to certain

metals. Carefully rinse piping thoroughly after leak

test has been completed.

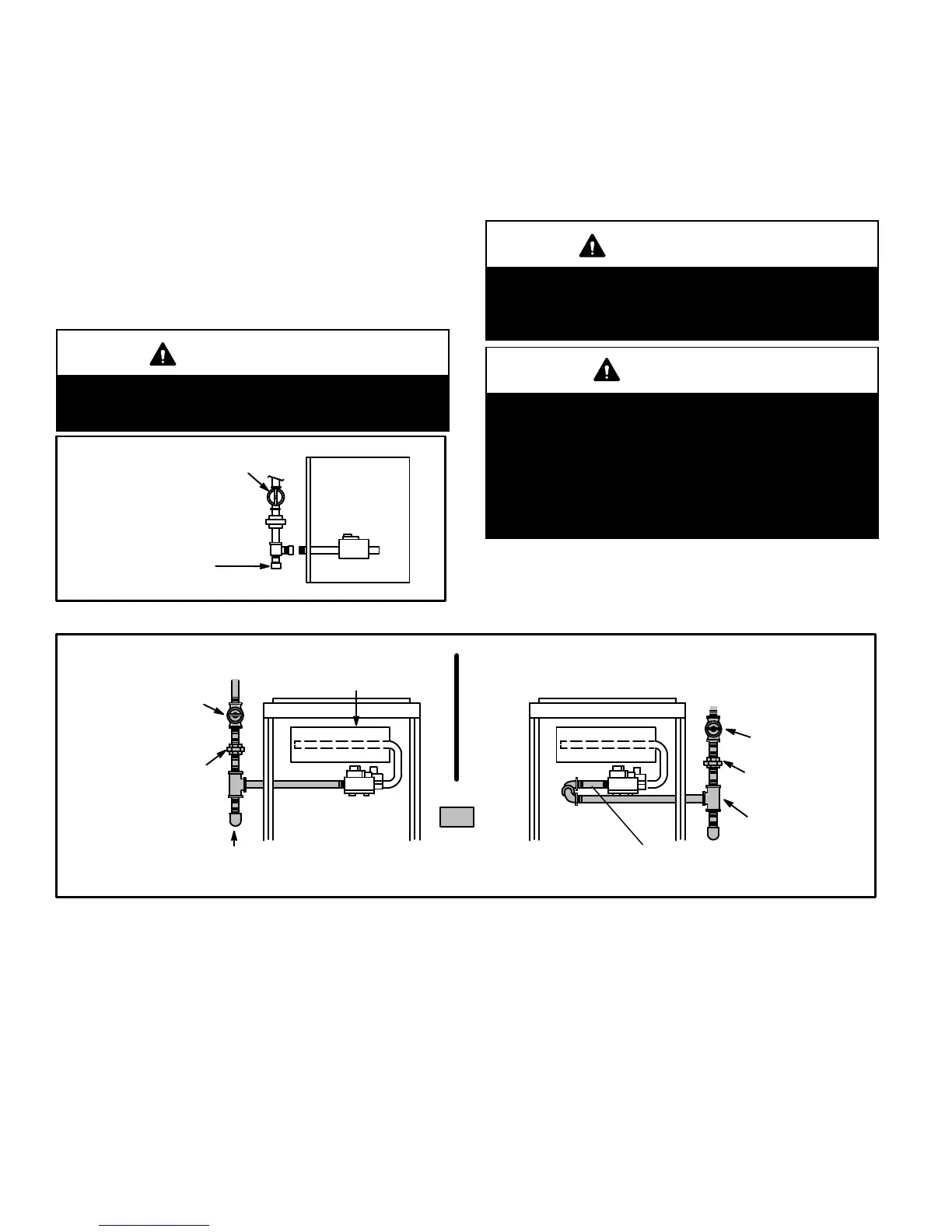

GROUND

JOINT

UNION

AUTOMATIC

GAS VALVE

(with manual

shut−off valve)

FIELD

PROVIDED

AND INSTALLED

Left Side Piping

(Standard)

DRIP LEG

MANUAL

MAIN SHUT−OFF

VALVE

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT−OFF

VALVE

Right Side Piping

(Alternate)

In LP/propane applications using a Honeywell

VR8205 gas valve, a 4" BIP nipple must be installed

to accommodate the low inlet pressure switch.

FIGURE 38

Loading...

Loading...