Page 34

During ignition spark travels through the spark (left) elec

trode and ignites the left burner. Flame travels from burner to

burner until all are lit. When flame is sensed by the right elec

trode (rightmost burner lit - indicated by microamp signal

through the flame) sparking stops. During operation, flame is

sensed by current passed along the ground electrode,

through the flame and into the sensing electrode. The igni

tion control allows the gas valve to stay open as long as a

flame signal (current passed through the flame) is sensed.

1-Spark Electrode

The spark electrode is connected to the ignition control

by a 5mm silicone insulated stranded high voltage

wire. The wire uses 1/4" female quick connect on the

electrode end and female spark plug-type terminal on

the ignition control end.

NOTE-IN ORDER TO MAXIMIZE SPARK ENERGY

TO ELECTRODE, HIGH VOLTAGE WIRE SHOULD

TOUCH UNIT CABINET AS LITTLE AS POSSIBLE.

2-Flame Sensor

Flame is sensed by rectification through the flame

sensing electrode.

N-Cooling Components

Summary of Features

Every GCS16-1853 uses three independent cooling circuits

consisting of three compressors, condenser coils and evap

orator coils. Vapor circuitry is shown in figure 31 and liquid

circuitry is shown in figure 32. Two draw-through type con

denser fans draw air across all three condenser coils during

all compressor operation. A single belt drive blower draws air

across all three evaporators during all unit operation. Cooling

may also be supplemented by fieldinstalled economizer.

The evaporators are slab type and are stacked as shown in

figure 35. Each evaporator uses a non-adjustable externally

equalized 5 ton expansion valve as the primary expansion

device. Each evaporator is also equipped with enhanced fins

and rifled tubing. The two condenser coils are split into three

independent circuits. Compressor 1 uses an independent

circuit in the right condenser coil (figure 31), compressor 2

uses an independent circuit in the left condenser coil and

compressor 3 uses an independent circuit split between the

left and right condenser coils. Each compressor is protected

by a crankcase heater, high pressure switch and loss of

charge switch. Additional protection is provided by factory

installed low ambient thermostat (unit control box) and free

zestats (on each evaporator). Each cooling circuit is

equipped with a thermometer well for charging.

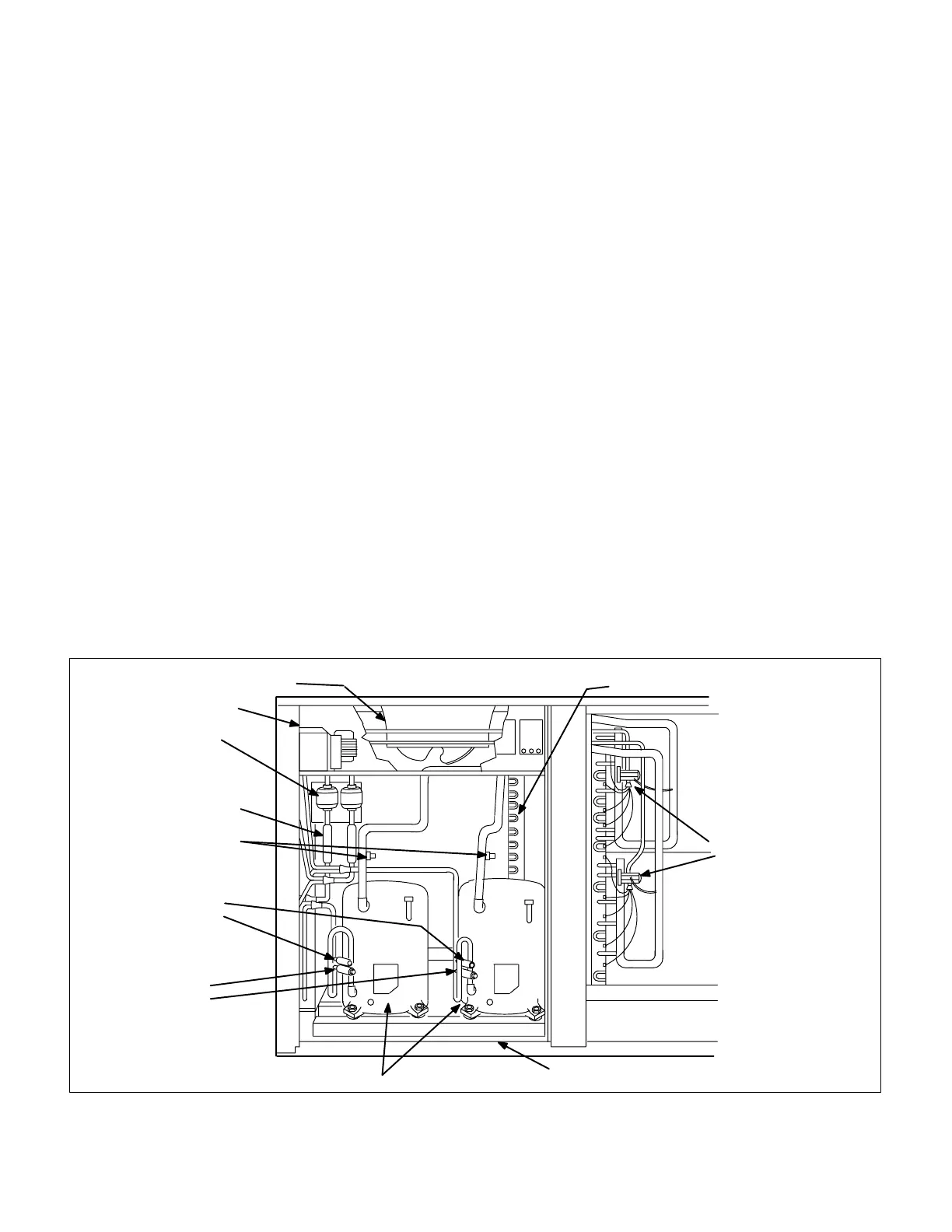

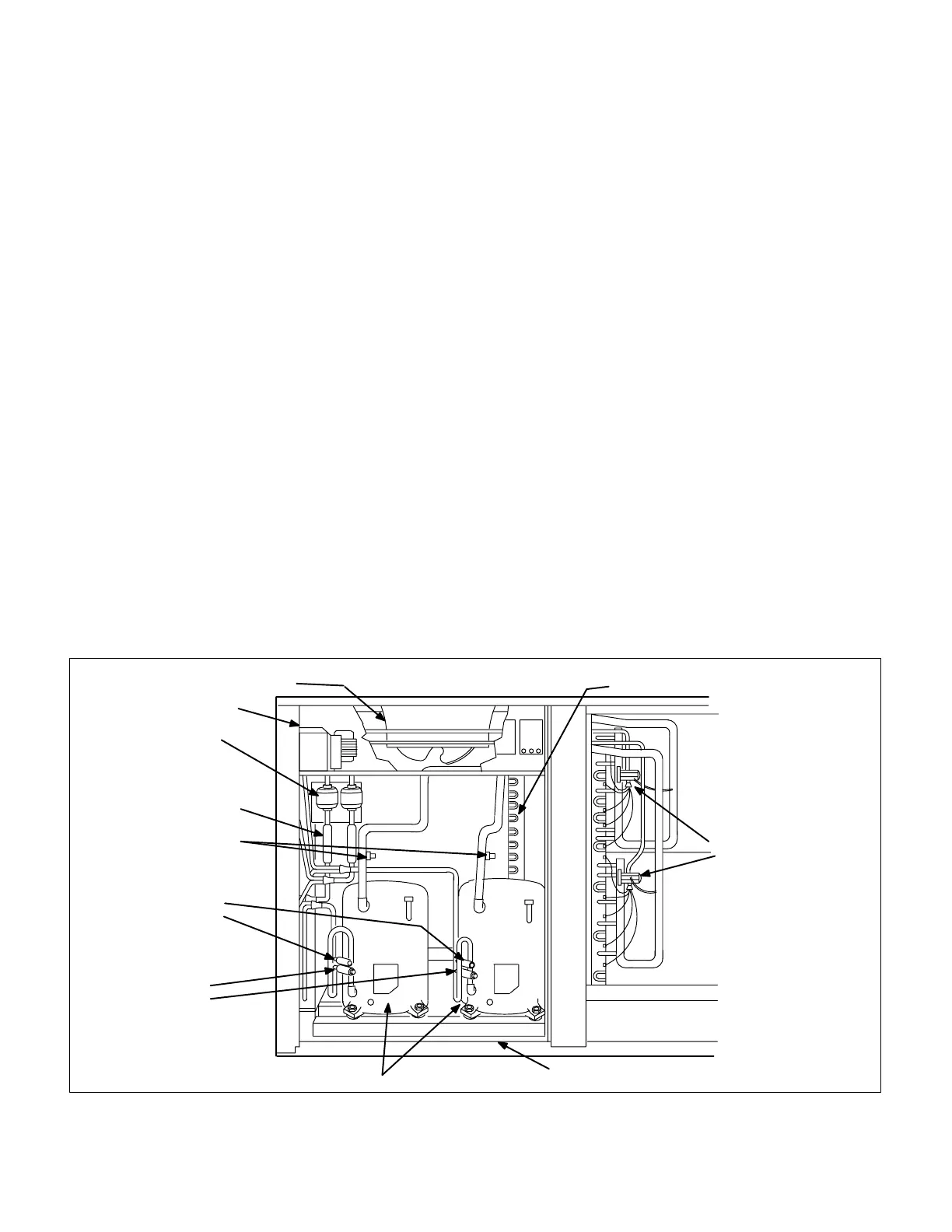

GCS16823, 953 PLUMBING COMPONENTS

FIGURE 29

FAN CONDENSER COILS

CONTROL BOX

DRIERS

THERMOMETER

WELLS and

LIQUID LINE

SERVICE PORTS

SUCTION LINE

SERVICE

PORTS

LOSS OF CHARGE

SWITCH (S24)

SWITCH (S25)

HIGH PRESSURE

LIMIT (S7)

LIMIT (S4)

COMPRESSOR

SERVICE ACCESS

OPENING

2ND STAGE

EVAPORATOR

1ST STAGE

EVAPORATOR

EXPANSION

VALVE

1ST STAGE2ND STAGE

Loading...

Loading...