Page 38

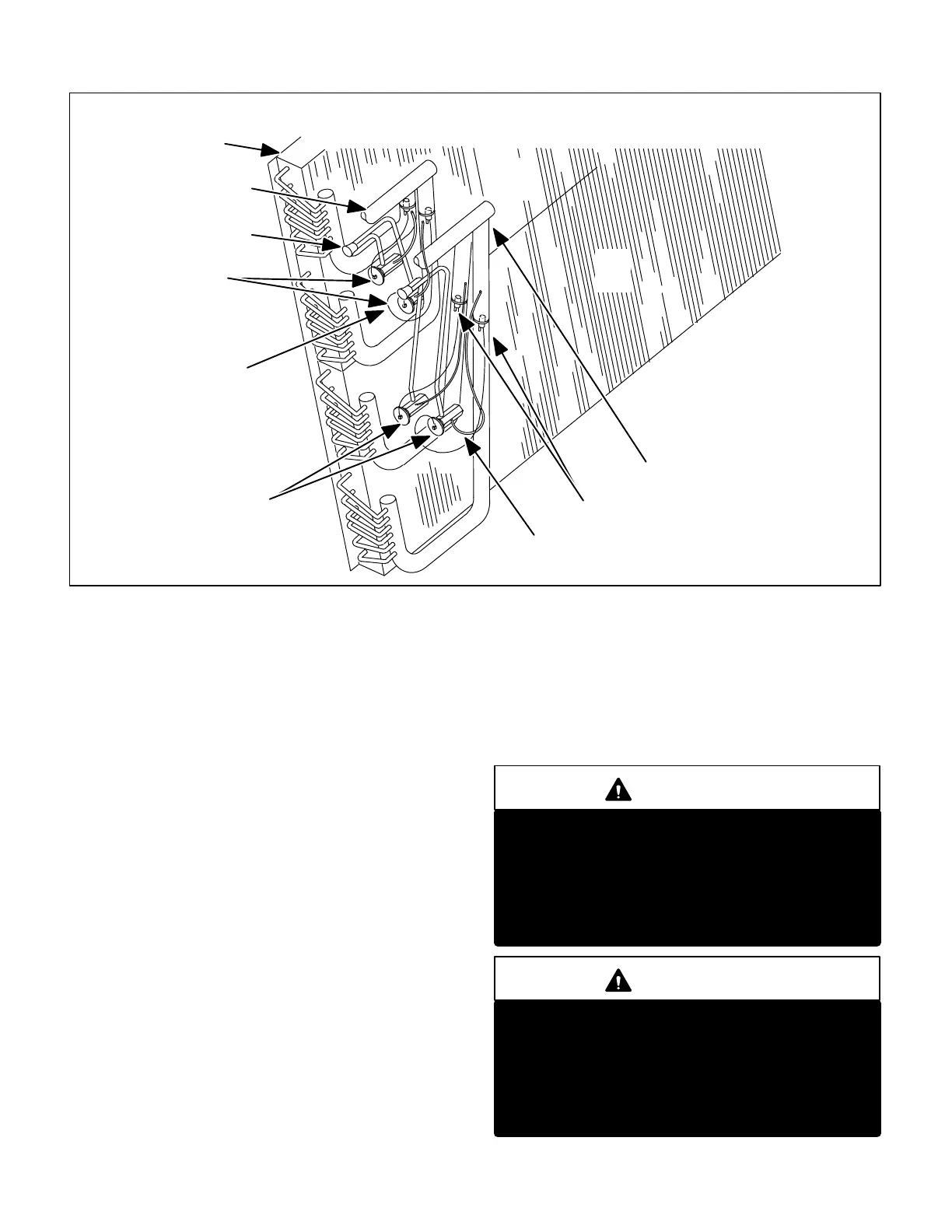

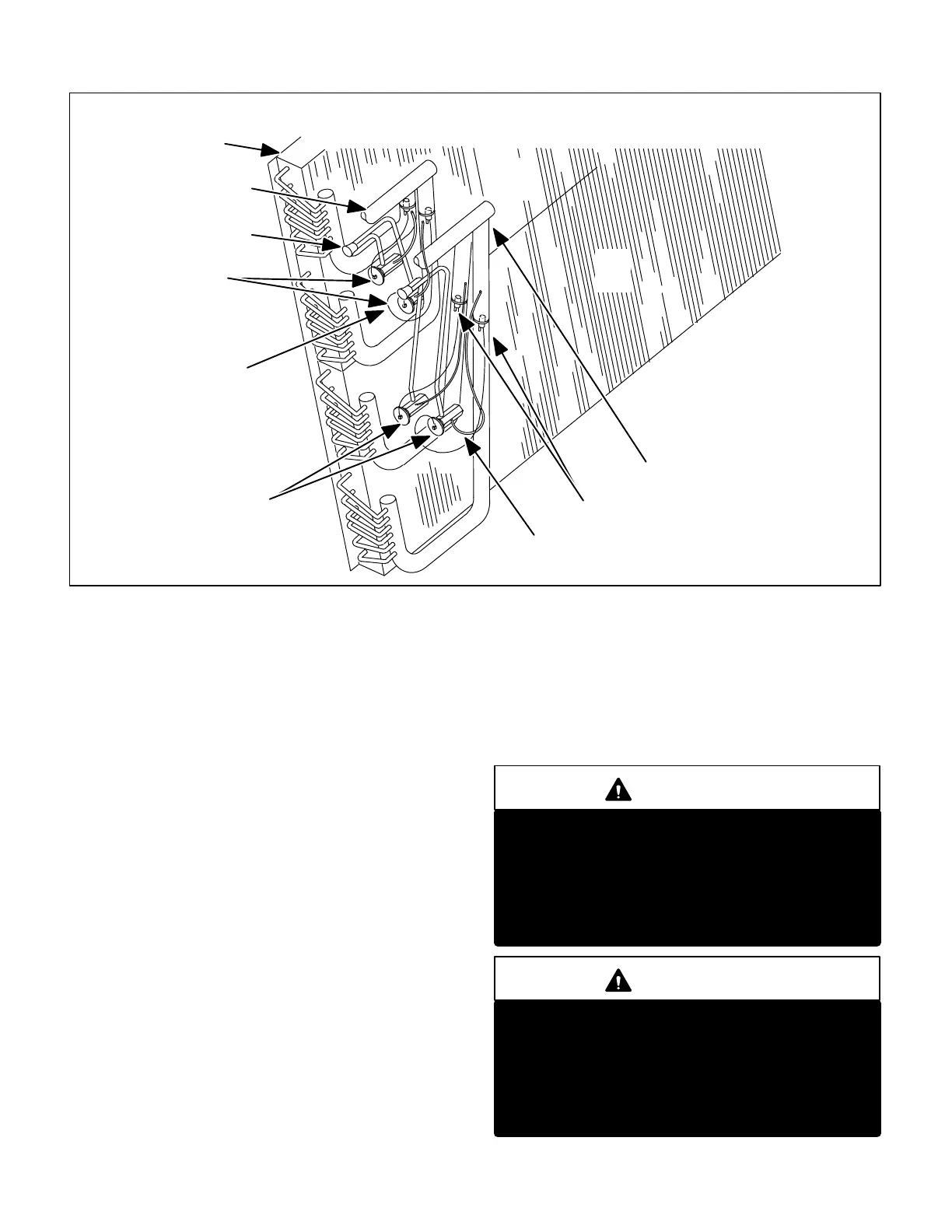

FIGURE 36

GCS162553, 2753, 3003 PLUMBING COMPONENTS

EVAPORATOR SECTION

2

1

1st STAGE SUCTION

RETURN TO COMPRESSOR

1st STAGE

COMP. 1

EVAPORATOR COIL

2nd STAGE

COMP. 2

EVAPORATOR COIL

DUAL 1st STAGE

EXPANSION VALVES

DUAL 2nd STAGE

EXPANSION VALVES

2nd STAGE LIQUID

LINE FROM OUTDOOR COIL

1st STAGE LIQUID

LINE FROM OUTDOOR COIL

SENSING BULBS

EQUALIZER LINES

2nd STAGE SUCTION

RETURN TO COMPRESSOR

1-Compressors B1, B2 and B13

Compressors are supplied by various manufacturers. All units

are equipped with two independent cooling circuits except 15

ton units which are equipped with three independent cooling

circuits. Compressor electrical specifications vary by

manufacturer. Likewise, compressor capacity may vary from

first stage to second stage. In all cases, the capacity of each

compressor is added to reach the total capacity of the unit.

See unit rating plate for specific compressor capacity ratings

and electrical data.

Units with two cooling circuits:

Compressor B1 is compressor 1. It operates during all

cooling demand and is energized by contactor K1 upon re

ceiving a first stage demand. Compressor B2 is compres

sor 2. It operates only during second stage cooling de

mand and is energized by contactor K2 upon receiving a

second stage demand.

NOTE-Refer to wiring diagram section B9 for specific

unit operation.

Units with three cooling circuits:

Compressor B1 is compressor 1. It operates during all cool

ing demand and is energized by contactor K1 upon receiv

ing a first stage demand. Compressor B2 is compressor 2.

It operates only during first stage cooling demand and is en

ergized by contactor K2 upon receiving a first stage de

mand (after time delay DL15 closes). Compressor B13 is

compressor 3. It is energized by contactor K14 upon receiv

ing a second stage demand.

Each compressor used in GCS16 units is equipped with a

selfregulating crankcase heater. All compressors are pro

tected by internal overload protection circuitry.

WARNING

Electrical shock hazard. Compressor must be

grounded. Do not operate without protective cov

er over terminals. Disconnect power before re

moving protective cover. Discharge capacitors

before servicing unit. Failure to follow these pre

cautions could cause electrical shock resulting in

injury or death.

WARNING

Crankcase heaters must be energized for 24

hours before attempting to start compressors.

Set thermostat so there is no compressor demand

before closing disconnect switch. Attempting to

start compressors during the 24hour warmup

period could result in damaged or failed compres

sors.

Loading...

Loading...