Page 45

6- Turn on power to unit. Follow lighting instructions

attached to unit and operate unit in heating mode.

Check burner flames. They should be blue with

yellow streaks.

NOTE-If the unit is operated with the heating access

panel off and burners cold, the burner sound will in

creased due to cold, dense primary air. This is normal

and will subside as the heat exchanger warms up during

operation. The sound will be even further reduced with

the access panel in place.

I-Heat Exchanger

To Access or Remove Heat Exchanger From Unit:

1- Turn off gas and electric power.

2- Remove access panel and unit end panel.

3- Remove gas valve, manifold assembly and burn

ers.

4- Remove combustion air blower and flue box. Pay

careful attention to the order in which gaskets and

orifice are removed.

5- Support heat exchanger (to prevent it from falling

when final bolts are removed.)

6- Remove bolts supporting heat exchanger.

7- To install heat exchanger, reverse procedure. Be

sure to secure all wires and check plumbing and

burner plate for airtight seal. Bolts must be torqued

to 35 inlbs. to ensure proper operation.

J-Ignition (Burner) Control A3

Ignition control A3 is factory set and is not adjustable. The

control makes three attempts at ignition and then locks out

the system if ignition is not obtained after the third trial. Re

set after lockout requires only breaking and remaking ther

mostat demand. The control shuts off gas flow immediate

ly in the event of a gas or power failure. Upon restoration of

gas and power, the control will restart the ignition se

quence and continue until flame is established or system

locks out.

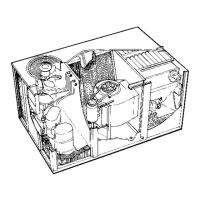

FIGURE 41

BURNER REMOVAL AND

ELECTRODE/SENSOR ORIENTATION

BURNER

AIR SLOTS

ORIFICE

OPENING

ELECTRODE/

FLAME SENSOR

ASSEMBLY

REMOVE SCREWS

TO REMOVE

ELECTRODE/SENSOR

REMOVE

SCREW

TO REMOVE

BURNERS

DANGER

Shock hazard. Spark related components contain

high voltage. Disconnect power before servicing.

For proper unit operation, the electrodes must be posi

tioned correctly in the flame and must be gapped cor

rectly.

WARNING

The ignition control is not field repairable. Unsafe

operation will result.

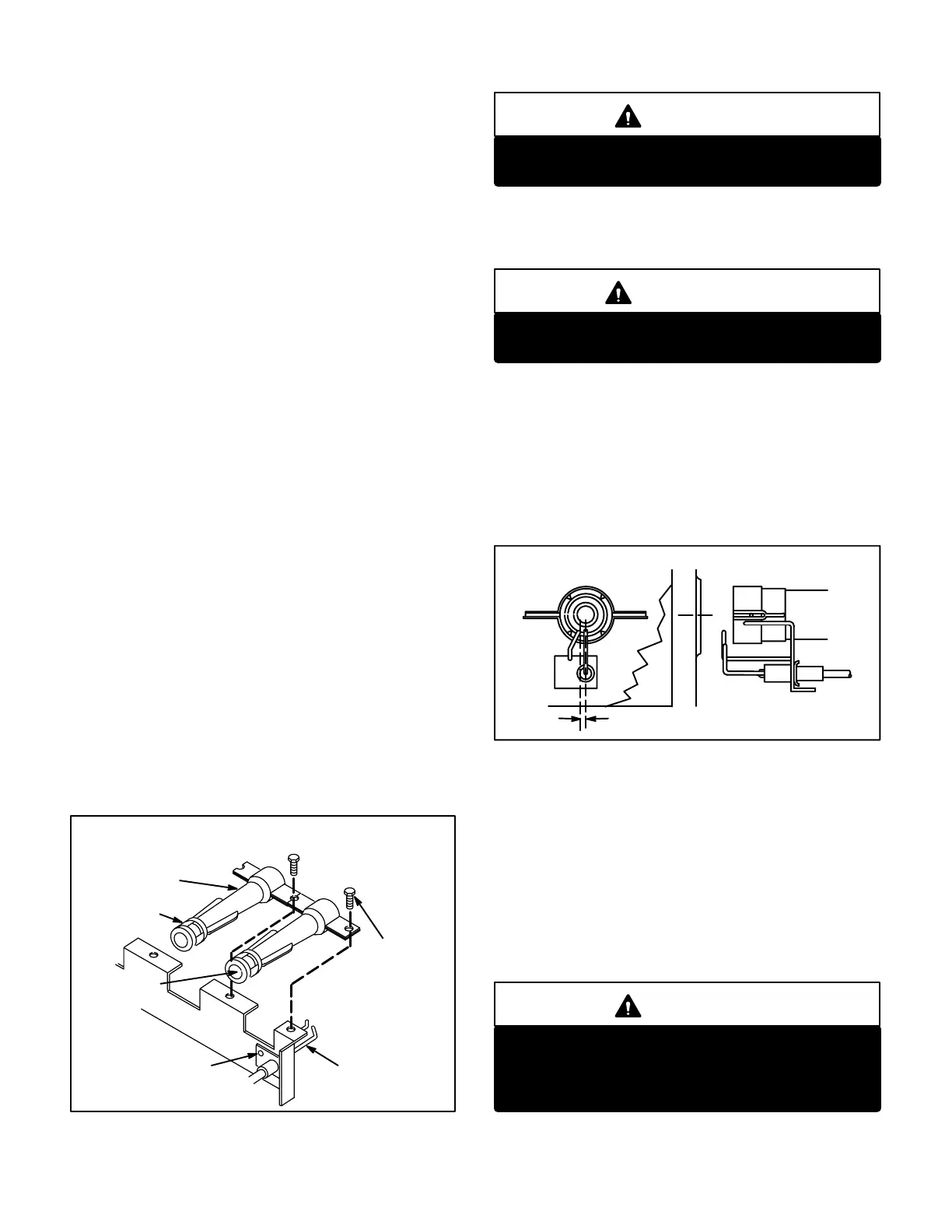

K-Spark Electrode/Flame Sensor Gap

The electrode assembly can be removed for inspection by

removing two screws securing the electrode assembly

and sliding it out of unit.

Spark gap may be checked with appropriately sized twist

drills or feeler gauges. Disconnect power to the unit and

remove electrode assembly. The gap should be between

0.094" and 0.156". See figure 42.

SPARK ELECTRODE and FLAME SENSOR GAP

FIGURE 42

1/8" + 1/32"

SENSOR/ELECTRODE GAP

L-Flame Sensing

Flame current is an electrical current which passes from the

ignition control through the sensor electrode during unit op

eration. The current passes from the sensor through the

flame to ground electrode to complete a safety circuit. The

minimum flame current necessary to keep the ignitor from

lockout is 5 microamps. The electrodes should be located so

the tips are at least 1/2" inside the flame envelope. Do not

bend electrodes. To measure flame current, follow the pro

cedure below:

DANGER

Electrodes are not field adjustable. Any alter

ations to the electrode may create a hazardous

condition that can cause property damage or per

sonal injury.

1- Disconnect power to unit.

Loading...

Loading...