GENERAL

Page 10

505023M 08/11

Zone Control Panel Jumpers (Heat/Cool Staging)

Heating/Cooling staging jumpers prevent any rapid stag-

ing of the equipment. This section shows the recom-

mended settings for heating/cooling staging temperatures

and explains the temperature differentials for different

equipment configurations. In the diagrams, sine waves in-

dicate which stage operates during the rise and fall of dis-

charge air temperature for the different heating/cooling

staging jumpers. Recommended jumper settings are

shown in bold type.

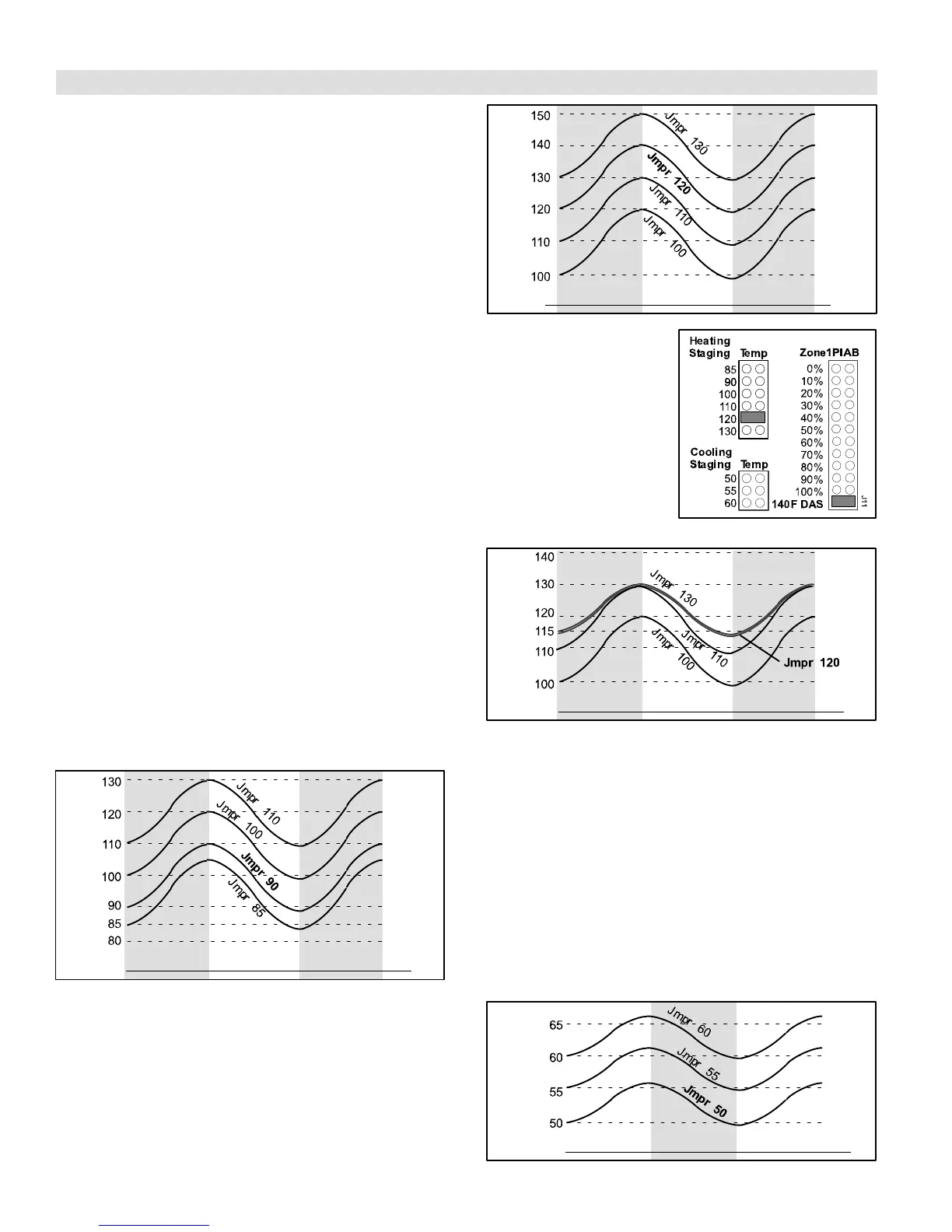

Heating Staging Temperature Jumper

Heating Staging temperature jumpers are used to set the

temperature at which the 2nd−stage heating equipment

comes ON. Its selections range from 85 − 130 (°F). The set-

ting has a built-in differential of 20°F (except as described

when 140DAS jumper is used).

During operation, when the discharge air temperature falls

below the jumper setpoint, 2nd-stage heating begins. If the

discharge air temperature reaches the differential temper-

ature, 2nd-stage operation ceases and 1st-stage heating

resumes until the temperature again falls below the jumper

set point.

NOTE − For G71MPP and SLP98 furnaces only, the fur-

nace ignition control will automatically adjust firing rate

without a 2nd stage heat demand to match the blower air-

flow (CFM) requested by the Harmony IIIt zoning system.

See Operation with G71MPP and SLP98" on page 26 for

additional information.

Heat Pump (range: 85 − 110°F, recommended: 90). The

maximum discharge air temperature at which the heat

pump/electric heat is allowed to run is fixed at 135°F.

105F

1ST STAGE2ND STAGE

TIME "

2ND STAGE

Discharge Air Temperature ºF

When the zone control system is applied to a heat pump

with electric heat, the electric heat will be staged ON to

maintain the discharge air temperature set by the heating

staging jumper position.

Gas Furnace with 160°F upper limit (range: 100 − 130;

recommended: 120). The maximum discharge air temper-

ature at which the furnace may run is fixed at 160°F.

Discharge Air Temperature ºF

1ST STAGE2ND STAGE

TIME "

2ND STAGE

Gas Furnace w/140F DAS

jumper (range: 100 − 130;

recommended: 120). When

the 140F DAS jumper is in

place (as shown to the

right), the maximum dis-

charge air temperature at

which the furnace may run

is fixed at 140°F. (Note the

140F DAS jumper’s impact

on the differential at 120

and 130 settings):

1ST STAGE2ND STAGE

TIME "

2ND STAGE

Discharge Air Temperature ºF

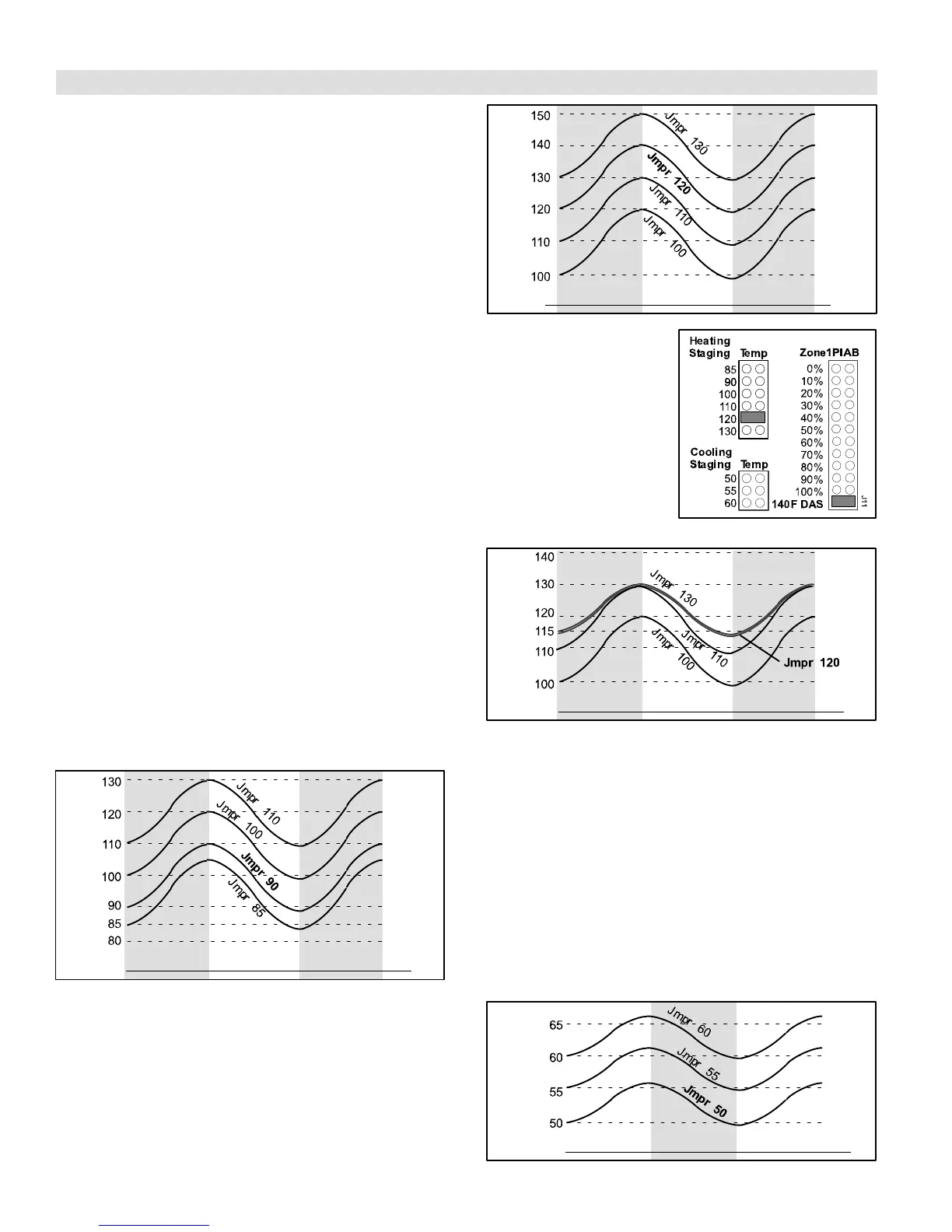

Cooling Staging Temperature Jumper

Cooling Staging temperature jumpers are used to set the

discharge air temperature at which 2nd−stage cooling

comes on. It is selectable between 50°, 55° and 60°F. A 7

degree total differential is associated with this staging tem-

perature, beginning at the jumper setpoint, and extending

to 7 degrees above the setpoint.

For any jumper setting, if the discharge air should fall to

45°F and any zone still demands cooling, the compressor

will not run leaving only the blower to operate until the dis-

charge air once again rises to 50°F and the 5 minute com-

pressor OFF delay has been satisfied. For this reason, and

to better satisfy latent loads, the jumper recommended

setting is 50.

1ST STAGE 2ND STAGE

67F

62F

57F

1ST STAGE

TIME "

Discharge Air Temperature

ºF

Loading...

Loading...