Page 27

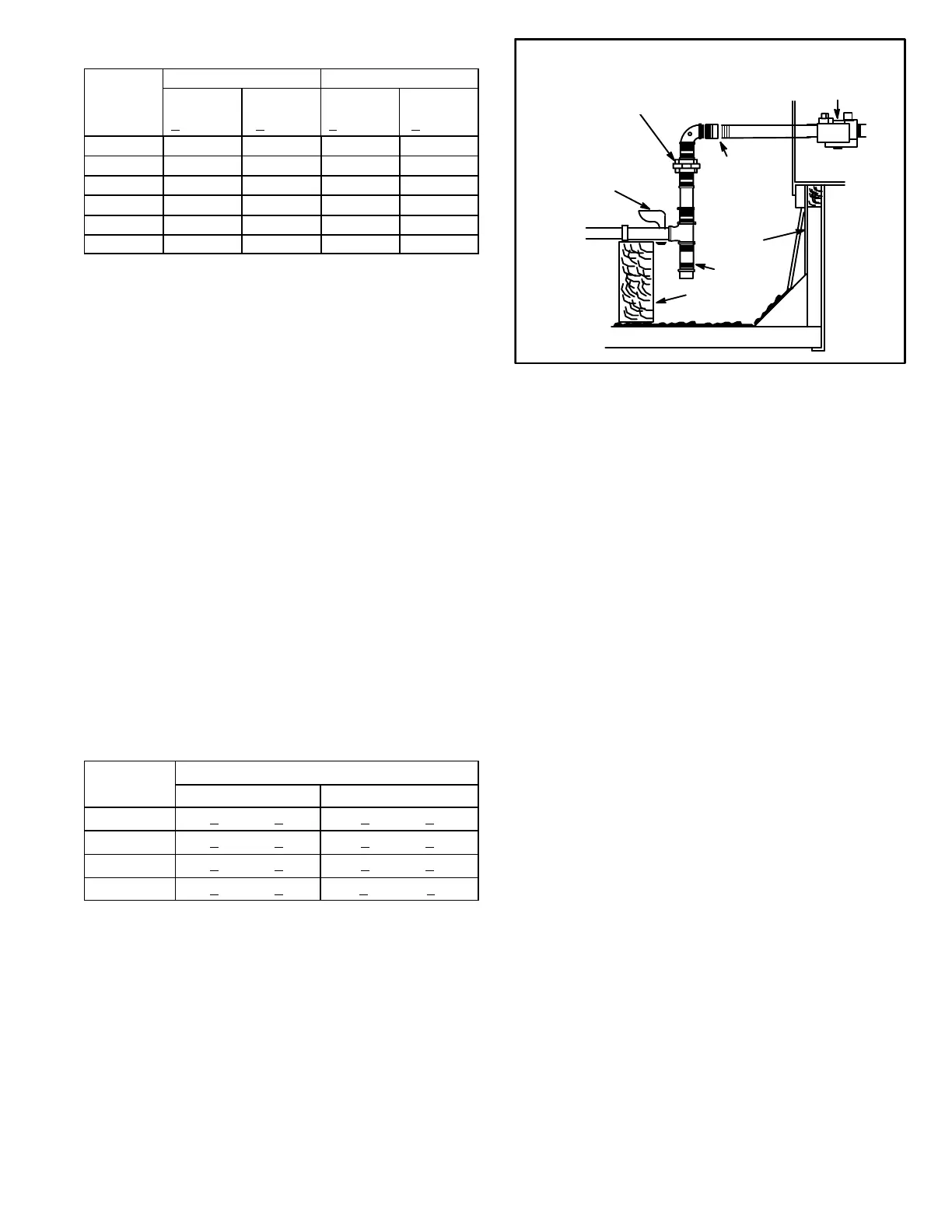

TABLE 10

KGA150 NORMAL OPERATING PRESSURES

Outdoor

Coil

Entering

Air Temp

CIRCUIT 1 CIRCUIT 2

Dis

charge

+

10 psig

Suction

+

5 psig

Dis

charge

+

10 psig

Suction

+

5 psig

655 F 279 132 283 136

755 F 318 134 323 138

855 F 360 136 364 139

955 F 406 138 411 140

1055 F 456 141 462 142

1155 F 508 145 515 145

Charge Verification - Approach Method - AHRI Testing

1- Using the same thermometer, compare liquid tempera

ture

(at condenser outlet) to outdoor ambient tempera

ture.

Approach Temperature = Liquid temperature minus

ambient temperature.

2- Approach temperature should match values shown in

table 11. An approach temperature greater than

this val

ue

indicates an undercharge. An approach tempera

ture less than

this value indicates an overcharge.

3- The approach method is not valid for grossly over

charged or undercharged systems.

Use tables 7

through 10

as a guide for typical operating pressures.

TABLE 11

APPROACH TEMPERATURE

Unit

Liquid Temp. Minus Ambient Temp.

1st Stage 2nd Stage

092 9°F + 1 (5.0°C + 0.5) 8°F + 1 (4.4°C + 0.5)

102 7°F + 1 (3.9°C + 0.5) 6°F + 1 (3.3°C + 0.5)

120 8°F + 1 (4.4°C + 0.5) 6°F + 1 (3.3°C + 0.5)

150 6°F + 1 (3.3°C + 0.5) 6°F + 1 (3.3°C + 0.5)

V- SYSTEMS SERVICE CHECKS

A-Heating System Service Checks

All KGA units are ETL/CSA design certified without mod

ification.

Before checking piping, check with gas company or au

thorities having jurisdiction for local code requirements.

Refer to the KGA Installation instruction for more infor

mation.

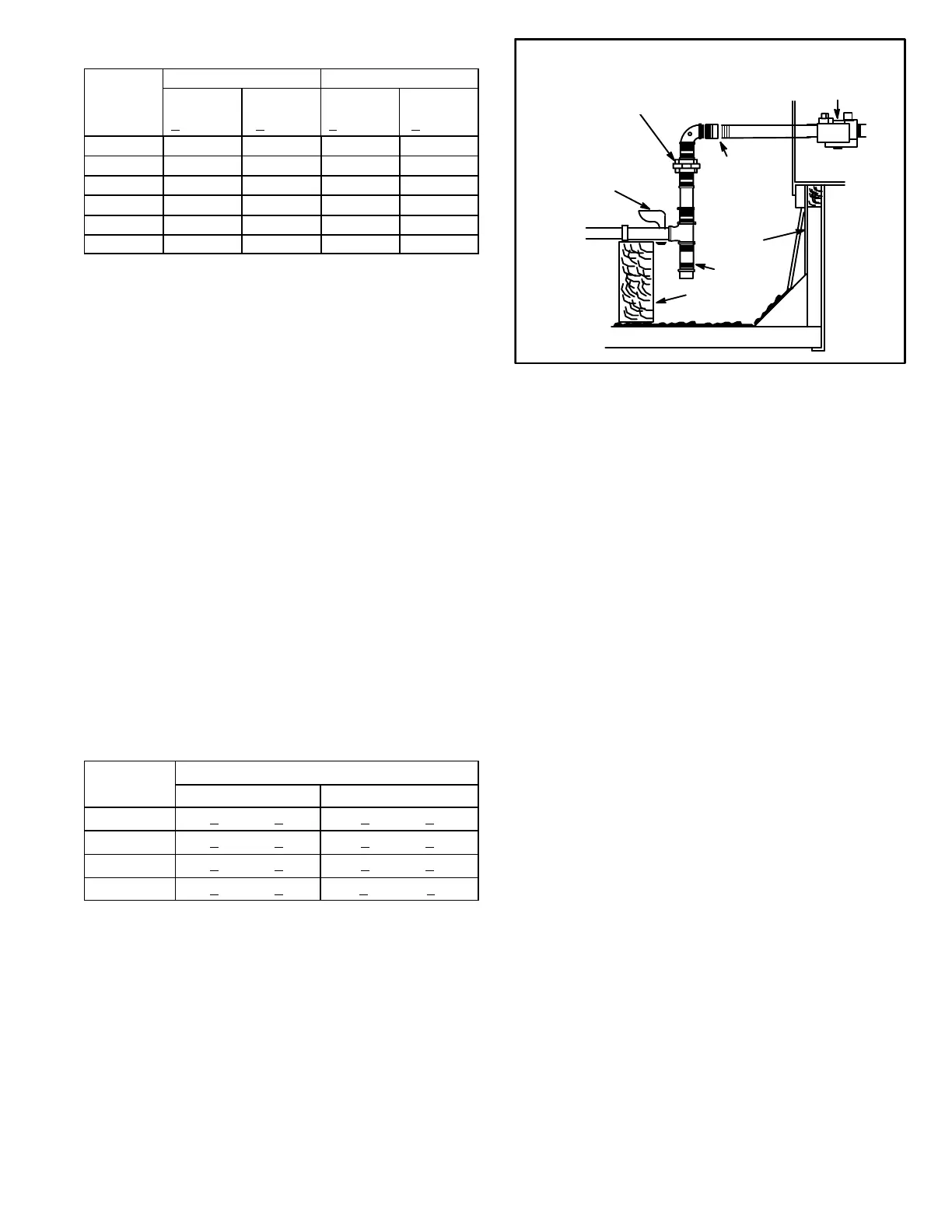

UNIT

GROUND

JOINT UNION

MANUAL MAIN

SHUT-OFF VALVE

(REFER TO LOCAL CODES)

GAS PIPING

SUPPORT

DRIP LEG

ROOF

MOUNTING

FRAME

GAS PIPING COMPONENTS

REFER TO INSTALLATION INSTRUCTIONS

VALVE

CAP HERE TO

ISOLATE VALVE

WHEN PRESSURE

TESTING LINE

FIGURE 20

1-Gas Piping

Gas supply piping must not allow more than 0.5”W.C.

(124.3 Pa) drop in pressure between the gas meter and

the unit. Supply gas pipe must not be smaller than the unit

gas connection. Refer to installation instructions for de

tails.

2-Testing Gas Piping

NOTE-In case emergency shutdown is required, turn off

the main manual shut‐off valve and disconnect the main

power to the unit. These controls should be properly la

beled by the installer.

When pressure testing gas lines, the gas valve must be dis

connected and isolated. Gas valves can be damaged if

subjected to more than 0.5 psig [14”W.C. (3481 Pa)]. See

figure 20.

When checking piping connection for gas leaks, use the

preferred means. Common kitchen detergents can

cause harmful corrosion on various metals used in gas

piping. The use of specialty Gas Leak Detector is strong

ly recommended. It is available as part number

31B2001. See CORP 8411-L10, for further details.

Do not use matches, candles, flame or any other source of

ignition to check for gas leaks.

3-Testing Gas Supply Pressure

When testing gas supply pressure, connect test gauge to the

inlet pressure tap located on unit gas valve GV1. Test sup

ply gas pressure with unit firing at maximum rate (both

stages energized). Make sure the reading falls within the

range of the following values. Low pressure may result in

erratic operation or “underfire.” High pressure can result in

permanent damage to the gas valve or “overfire.” For nat

ural gas units, operating pressure at the unit gas connec

tion must be between 4.7”W.C. and 10.5”W.C. (1168 Pa

and 2610 Pa). For L.P. gas units, operating pressure at

the unit gas connection must be between 10.8”W.C. and

13.5”W.C. (2685.3 Pa and 3356.7 Pa).

Loading...

Loading...