Page 17

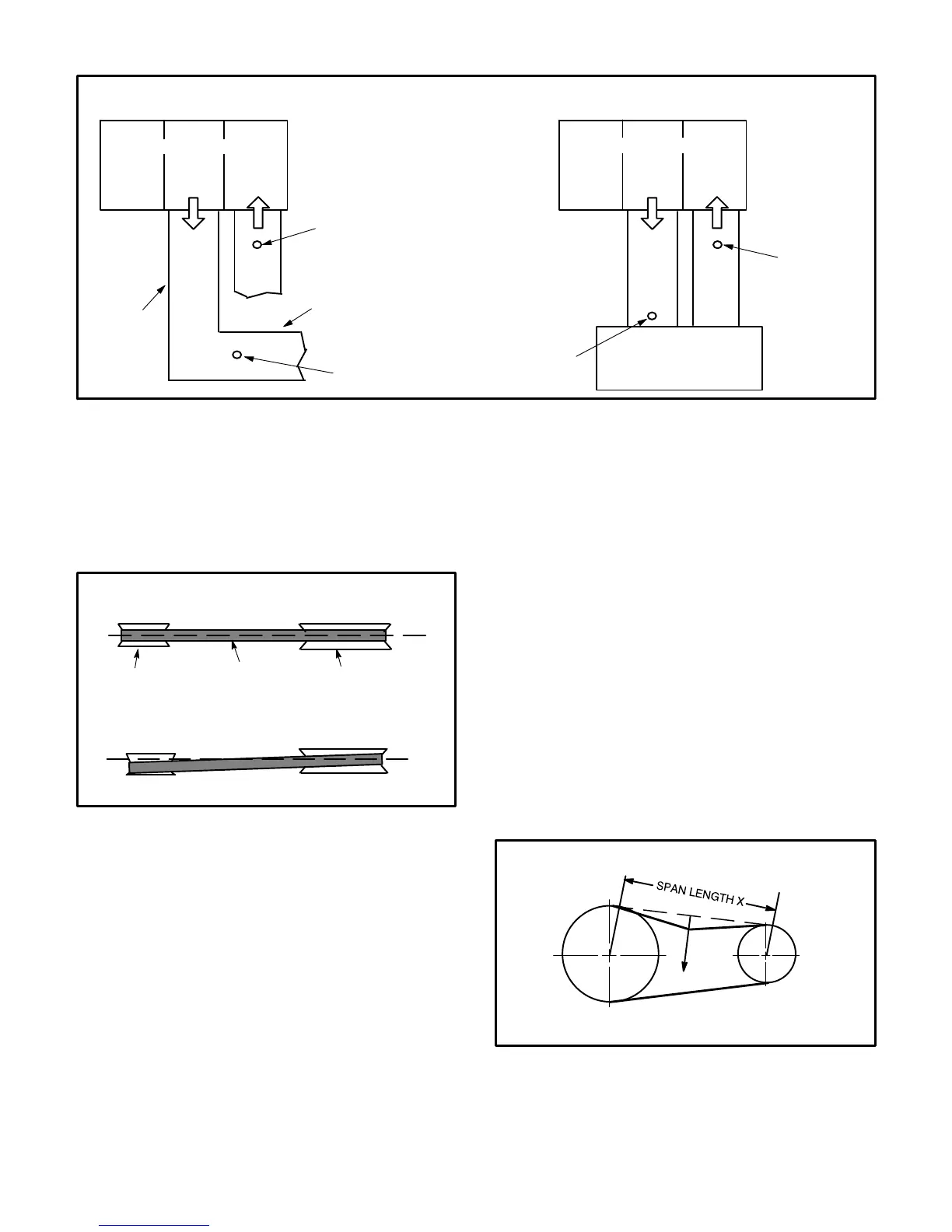

FIGURE 21

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

RE

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

RE

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

D-Blower Belt Adjustment - No Tensioner

Maximum life and wear can be obtained from belts only

if proper pulley alignment and belt tension are

maintained. Tension new belts after a 24-48 hour

period of operation. This will allow belt to stretch and

seat in the pulley grooves. Make sure blower and motor

pulleys are aligned as shown in figure 22.

FIGURE 22

PULLEY ALIGNMENT

BELT

BLOWER PULLEY

MOTOR PULLEY

NOT ALIGNED

ALIGNED

1- Loosen four bolts securing motor base to mounting

frame. See figure 18.

2- To increase belt tension -

Turn both adjusting bolts to the right, or clockwise, to

move the motor outward and tighten the belt. This

increases the distance between the blower motor and

the blower housing.

To loosen belt tension -

Turn the adjusting bolt to the left, or counterclockwise

to loosen belt tension.

IMPORTANT - Align edges of blower motor base and

mounting frame base parallel before tightening four

bolts on the side of base. Motor shaft and blower shaft

must be parallel.

3- Tighten bolts on side of base.

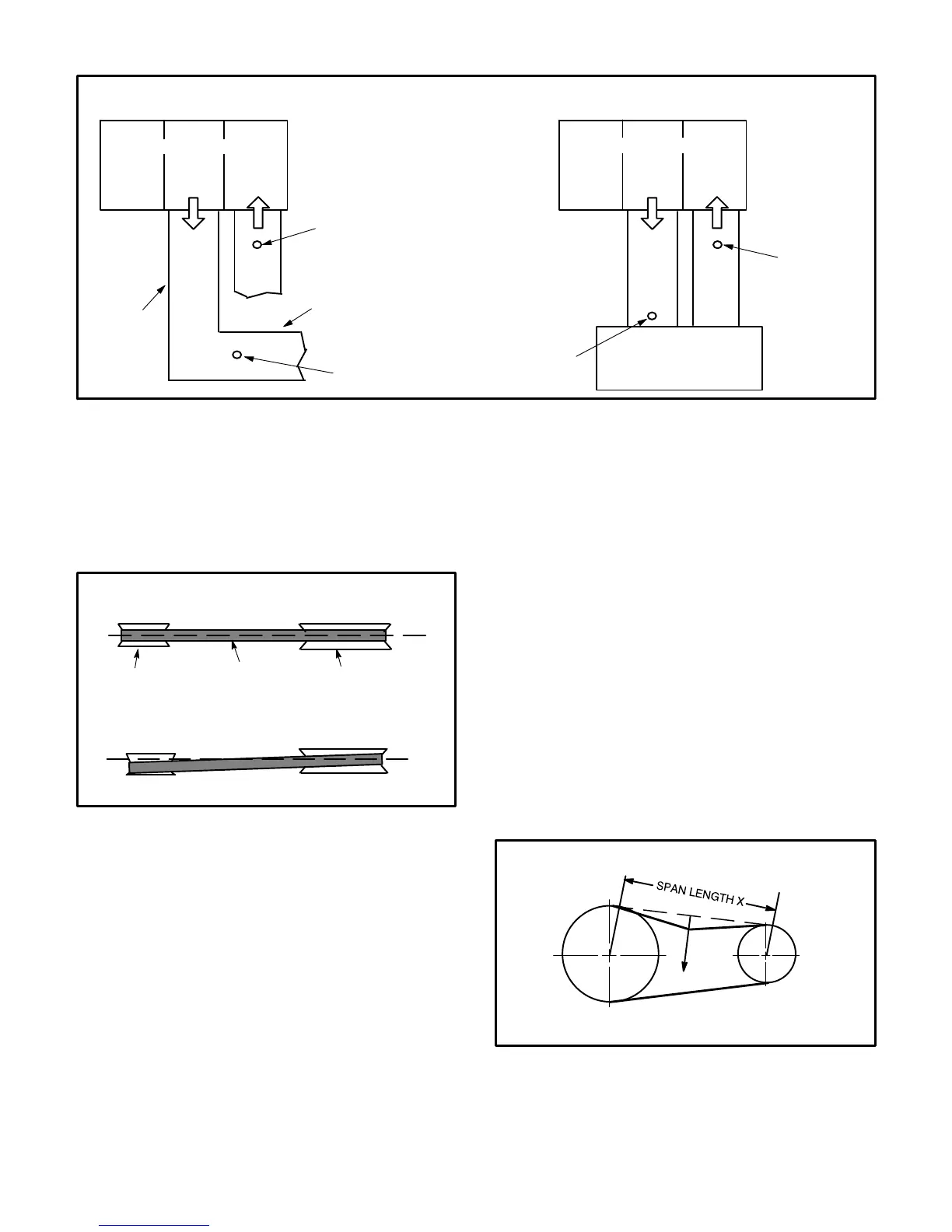

E-Check Belt Tension

Overtensioning belts shortens belt and bearing life.

Check belt tension as follows:

1- Measure span length X. See figure 23.

2- Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch

of span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 400mm span

would be 6mm.

3- Measure belt deflection force. For a new 2 and 3hp

belt, the deflection force should be 5.0-7.0 lbs.

(35-48kPa). For a new 5hp belt, the deflection force

should be 7-10lbs. (48-69kPa).

A force below these values indicates an

undertensioned belt. A force above these values

indicates an overtensioned belt.

MEASURE BELT TENSION

FIGURE 23

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FORCE

F-Field-Furnished Blower Drives

For field-furnished blower drives, use pages 16 through

18 to determine the drive kit number and table 4 or 5 for

drive component manufacturer's numbers.

Loading...

Loading...