Page 55

507124-04 3/2016

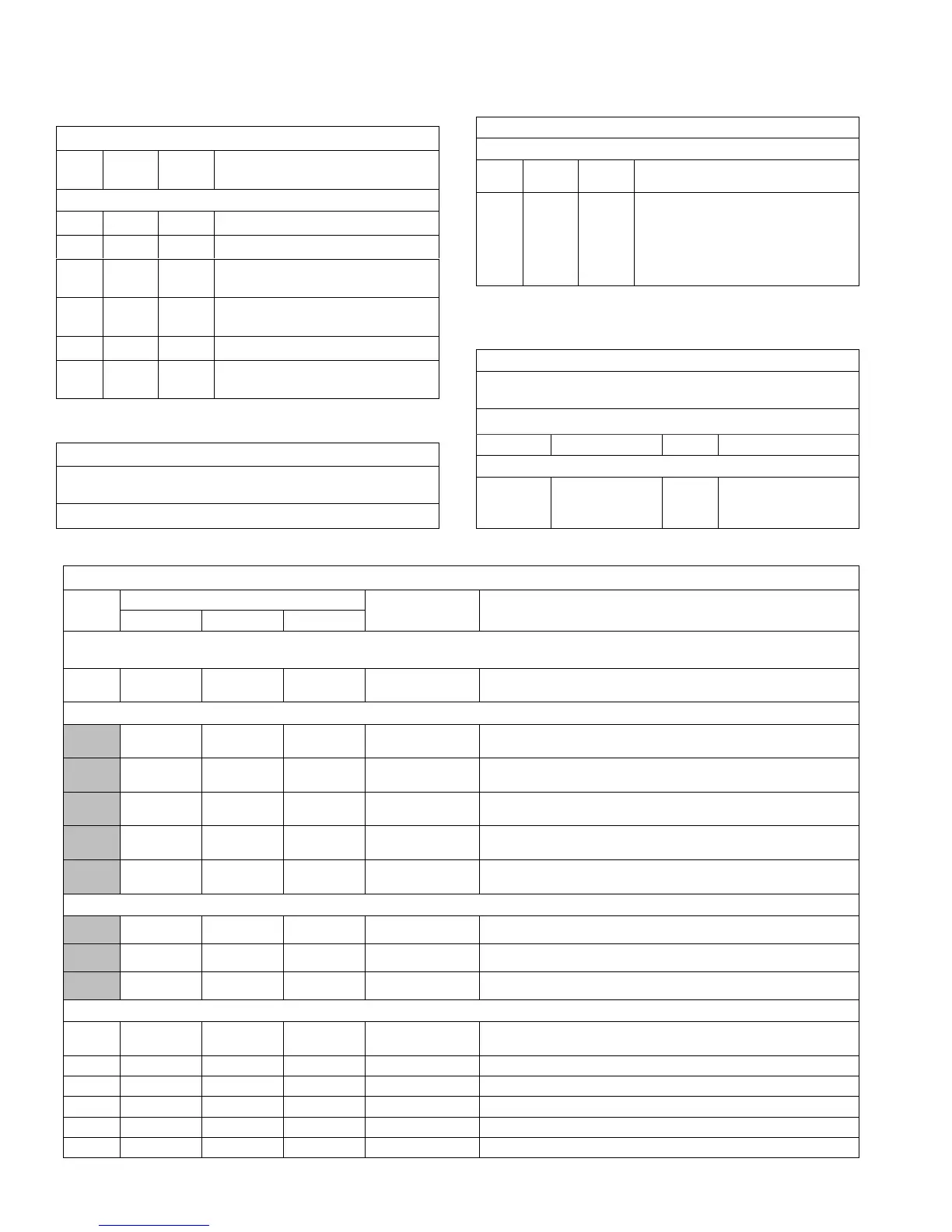

TABLE 29

580731

Units With Automated Logic DDC (Target) Settings

Para

meter

Factory

Setting

Field

Setting

Description

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

91 120 Compressor minimum run time.

111 3 Thermostat with three cooling stages.

118 400

Damper “start open” CO

2

setpoint for

DCV.

119 2000

Damper “full open” CO

2

setpoint for

DCV.

139 74 Backup occupied cooling setpoint.

153 60

Time delay between heating and cooling

mode.

TABLE 30

580732

Units With Room Sensor, CPC/LSE Gateway Settings

Use menu SETUP > NETWORK INTEGRATION. Set “L CONNEC

TION” and network address.

LCONN ADDRESS:

TABLE 31

580734

Units With Hot Gas Reheat

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

Para

meter

Factory

Setting

Field

Setting

Description

105 6

Hot Gas Reheat Option 6: Reheat is

only possible if blower is energized dur

ing occupied periods. Controlled by RH

sensor (A91) connected to input

A55_P298_5 and set point set at para

meter 106 (default 60%).

TABLE 32

580733

Units With BACnet Module (Kohl's) Settings

Use menu SETUP > NETWORK INTEGRATION. Set “BACNET”

and network address.

BACNET MAC ADDRESS:

Parameter Factory Setting Setting Description

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

137 65

Sets the backup occu

pied heating setpoint to

65F.

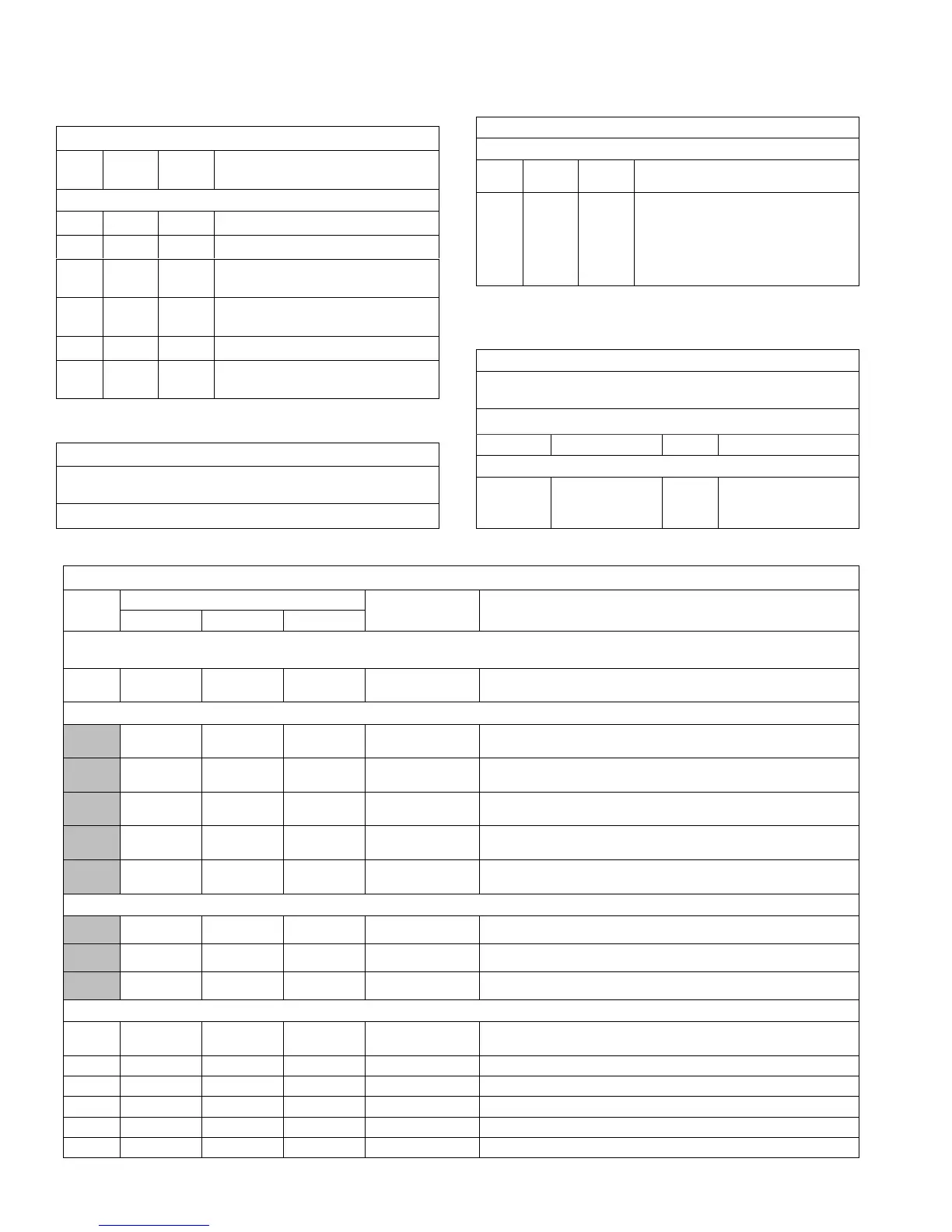

TABLE 33

580745

LGH/LCH 156H/180H/210H (3-Compressor) MSAV

Para-meter

Factory Setting

Field

Setting

Description

156 180 210

Note: Any changes to Smoke CFM setting must be adjusted before the other CFM settings. Use SETTINGS > RTU OPTIONS > EDIT

PARAMETERS

12

5200

CFM

6000

CFM

7000

CFM

CFM Blower CFM during smoke detection.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > BLOWER > SPEEDS)

5200

CFM

6000

CFM

7000

CFM

CFM

Blower CFM during heating.

4675

CFM

5400

CFM

6300

CFM

CFM

Blower CFM during compressor 3 operation.

3375

CFM

3900

CFM

4550

CFM

CFM

Blower CFM during compressor 2 operation.

3375

CFM

3900

CFM

4550

CFM

CFM

Blower CFM during compressor 1 operation.

5200

CFM

6000

CFM

7000

CFM

CFM

Blower CFM during ventilation.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > DAMPER)

0% 0% 0% % Damper min. position during LOW blower operation.

0% 0% 0% % Damper min. position during HIGH blower operation.

50% 50% 50% % Min. damper % for stage 1 power exhaust operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS

29 101% 101% 101% %Open

Damper minimum position during G blower operation. (Setting parameter 29 to

“101” disables parameter 29 and passes control to parameter 9 or 132)

219 70% 70% 70% % Min. damper % for stage 2 power exhaust operation.

216 10% 10% 10% % Deadband % for stage 1 power exhaust operation.

220 10% 10% 10% % Deadband % for stage 2 power exhaust operation.

224 100 100 100 Sec Stage 1 power exhaust off-delay in seconds.

30 70% 70% 70% %Speed Minimum blower speed % for stage 2 power exhaust operation.

Loading...

Loading...