Page 38

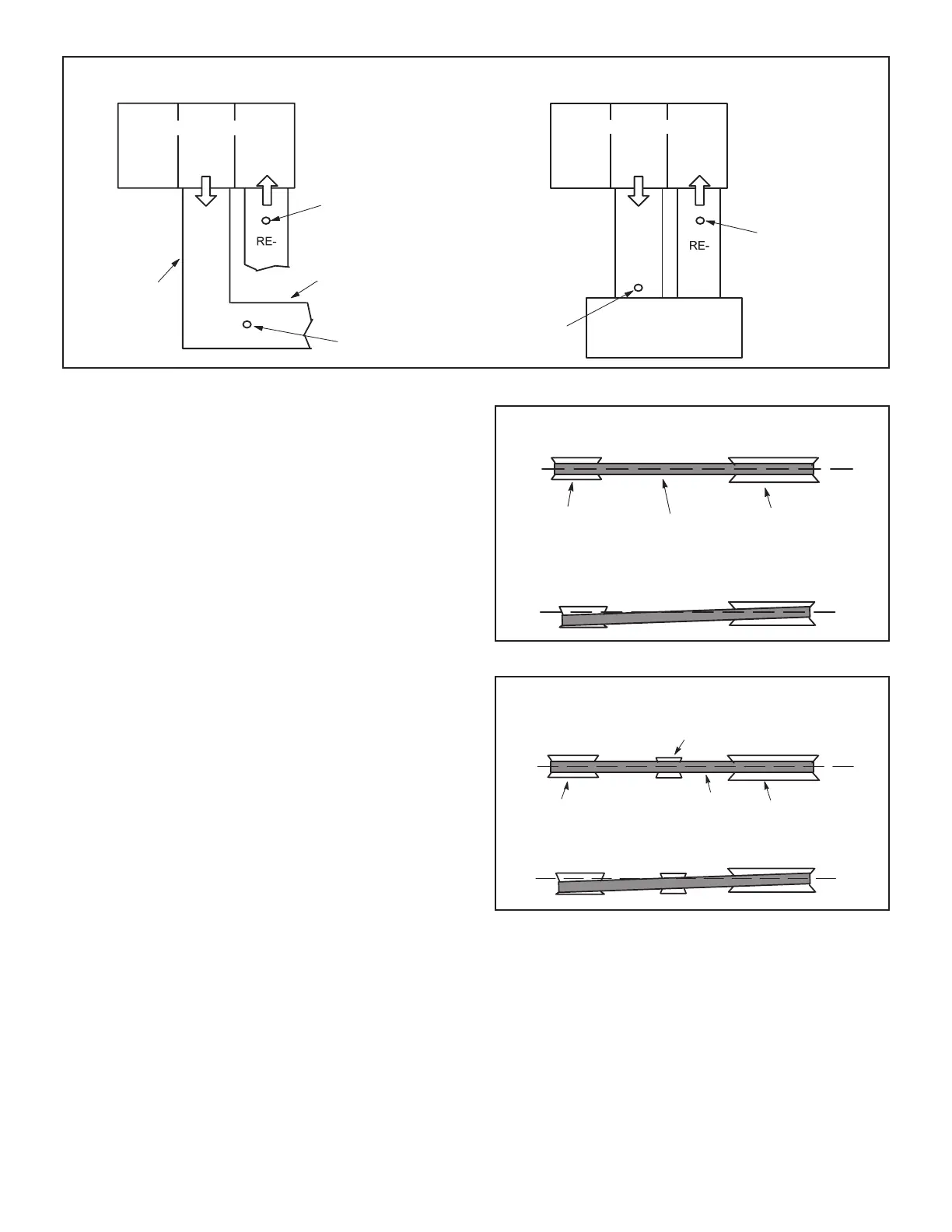

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

FIGURE 11

1 - The following measurements must be made with a

dry indoor coil. Run blower without cooling demand.

taken.

2 - With all access panels in place, measure static

pressure external to unit (from supply to return).

Blower performance data is based on static pressure

Note - Static pressure readings can vary if not taken

where shown.

3 - Measure the indoor blower wheel RPM.

4 - Refer to blower tables in BLOWER DATA (table

of contents) in the front of this manual. Use static

pressure and RPM readings to determine unit air

volume.

5 - The RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley

clockwise to increase RPM. Turn counterclockwise

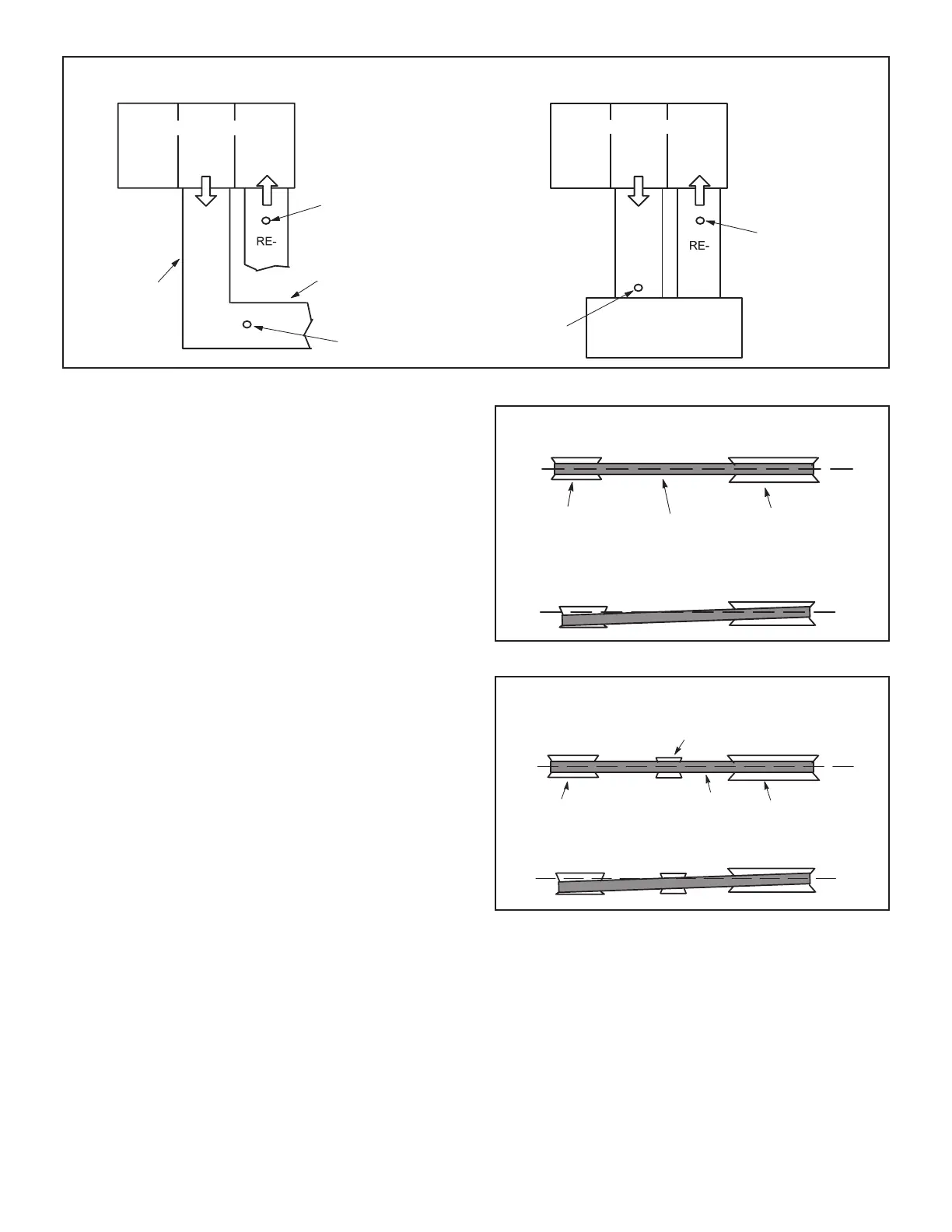

Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

Tension new belts after a 24-48 hour period of operation.

This will allow belt to stretch and seat into pulley grooves.

Make sure blower and motor pulley are aligned as shown

equipped with an optional belt tensioner.

Standard Blowers

1 - Loosen four screws securing blower motor to sliding

2 - To increase belt tension - Turn belt tension

adjusting screw to the left, or counterclockwise,

to tighten the belt. This increases the distance

between the blower motor and the blower housing.

To loosen belt tension - Turn the adjusting screw to

the right, or clockwise to loosen belt tension.

3 - Tighten four screws securing blower motor to sliding

base once adjustments have been made

PULLEY ALIGNMENT - NO TENSIONER

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

FIGURE 12

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

TENSIONER

PULLEY ALIGNMENT - WITH TENSIONER

FIGURE 13

Blowers Equipped With Belt Tensioner

1 - Loosen the bolt in the center of the tensioner. See

2 - Place belt over all three pulleys.

3 - Using a 15/16” wrench, turn the tensioner nut until

4 - Hold the tensioner with marks aligned and tighten

Loading...

Loading...