VIII-FACTORY-INSTALLED Hot Gas Re-Heat

General

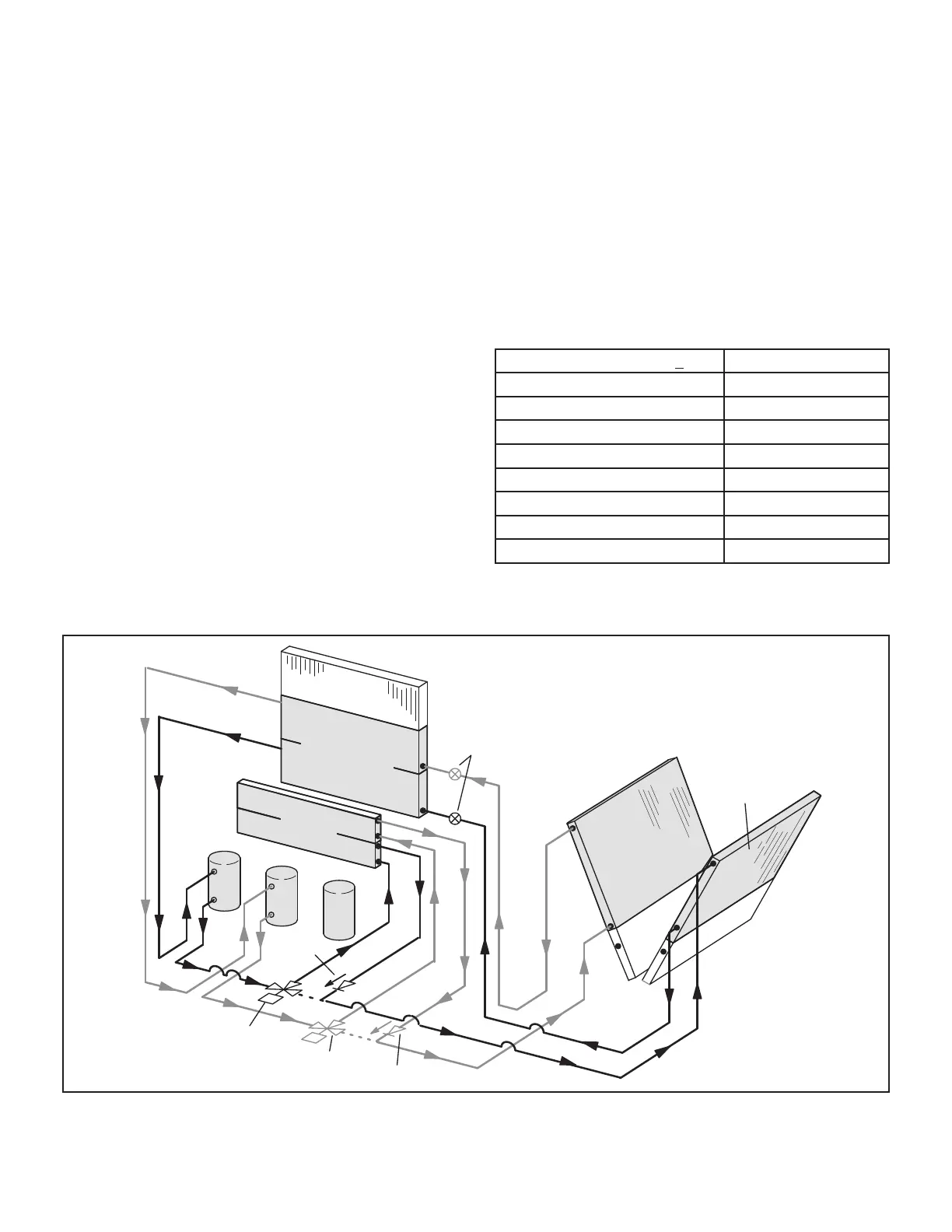

Hot Gas Re-Heat units provide a dehumidifying mode of

operation. These units contain a reheat coil adjacent to

and downstream of the evaporator coil. Reheat coil sole-

noid valves, L14 and L30, route hot discharge gas from

the compressor to the reheat coil. Return air pulled across

coil adds heat to supply air.

-

-

refrigerant routing.

L14 and L30 Reheat Coil Solenoid Valves

and refrigerant is routed to the reheat coil.

Reheat Setpoint

Reheat is factory-set to energize when indoor relative hu-

midity rises above 60% (default). The reheat setpoint can

be adjusted by changing Unit Controller Settings - Control

menu. A setting of 100% will operate reheat from an ener-

gy management system digital output. The reheat setpoint

can also be adjusted using an optional Network Control

Panel (NCP).

Reheat will terminate when the indoor relative humidity

falls 3% (57% default) or the digital output de-energizes.

The reheat deadband can be adjusted at Settings - Con-

trol menu.

A91 Humidity Sensor

relative humidity is 80% + 3%, the humidity sensor output

should read 8.00VDC.

Check the sensor output annually for accuracy. Keep the

air intake openings on the sensor clean and free of ob-

structions and debris

.

TABLE 39

Relative Humidity (%RH + 3%) Sensor Output (VDC)

20 2.00

30 3.00

40 4.00

50 5.00

60 6.00

70 7.00

80 8.00

REHEAT MODE REFRIGERANT ROUTING

156, 180H, & 210 UNITS

REHEAT

COIL

CIRCUIT 1

CONDENSER

COIL

CIRCUIT 2

CONDENSER

COIL

STAGE 2

EVAPORATOR

COIL

STAGE 1

EVAPORATOR

COIL

1

2

EXPANSION

VALVES

CHECK

L14

REHEAT

VALVE

L30

REHEAT

VALVE

3

CHECK

VALVE

Note: Two refrigerant circuits are shown; both

circuits operate during reheat.

FIGURE 36

Loading...

Loading...