Page 22

LHT/LDT156, 180, 240

11- The ignition sequence will start.

12- If the appliance does not light the first time (gas line

not fully purged), it will attempt up to two more

ignitions before locking out.

13- If lockout occurs, repeat steps 1 through 10.

14- If the appliance will not operate, follow the

instructions “Turning Off Gas to Appliance” and call

your service technician or gas supplier.

Turning Off Gas to Unit

1- If using an electromechanical thermostat, set to the

lowest setting.

2- Before performing any service, turn off all electrical

power to the appliance.

3- Open or remove the heat section access panel.

4- Turn gas valve switch to OFF.

5- Close or replace the heat section access panel.

WARNING

Danger of explosion. Can cause injury or

death. Do not attempt to light manually.

Unit has a direct spark ignition system.

Heating Operation and Adjustments

(Gas Units)

A-Heating Sequence of Operation

1- On a heating demand the combustion air inducer

starts immediately.

2- Combustion air pressure switch proves inducer

operation. After a 30-second pre-purge, power is

allowed to ignition control. Switch is factory set and

requires no adjustment.

3- Spark ignitor energizes and gas valve solenoid

opens.

4- Spark ignites gas, ignition sensor proves the flame

and combustion continues.

5- If flame is not detected after first ignition trial, ignition

control will repeat steps 3 and 4 two more times

before locking out the gas valve.

6- For troubleshooting purposes, an ignition attempt

after lock out may be re-established manually. Move

thermostat to “OFF” and return thermostat switch to

“HEAT” position.

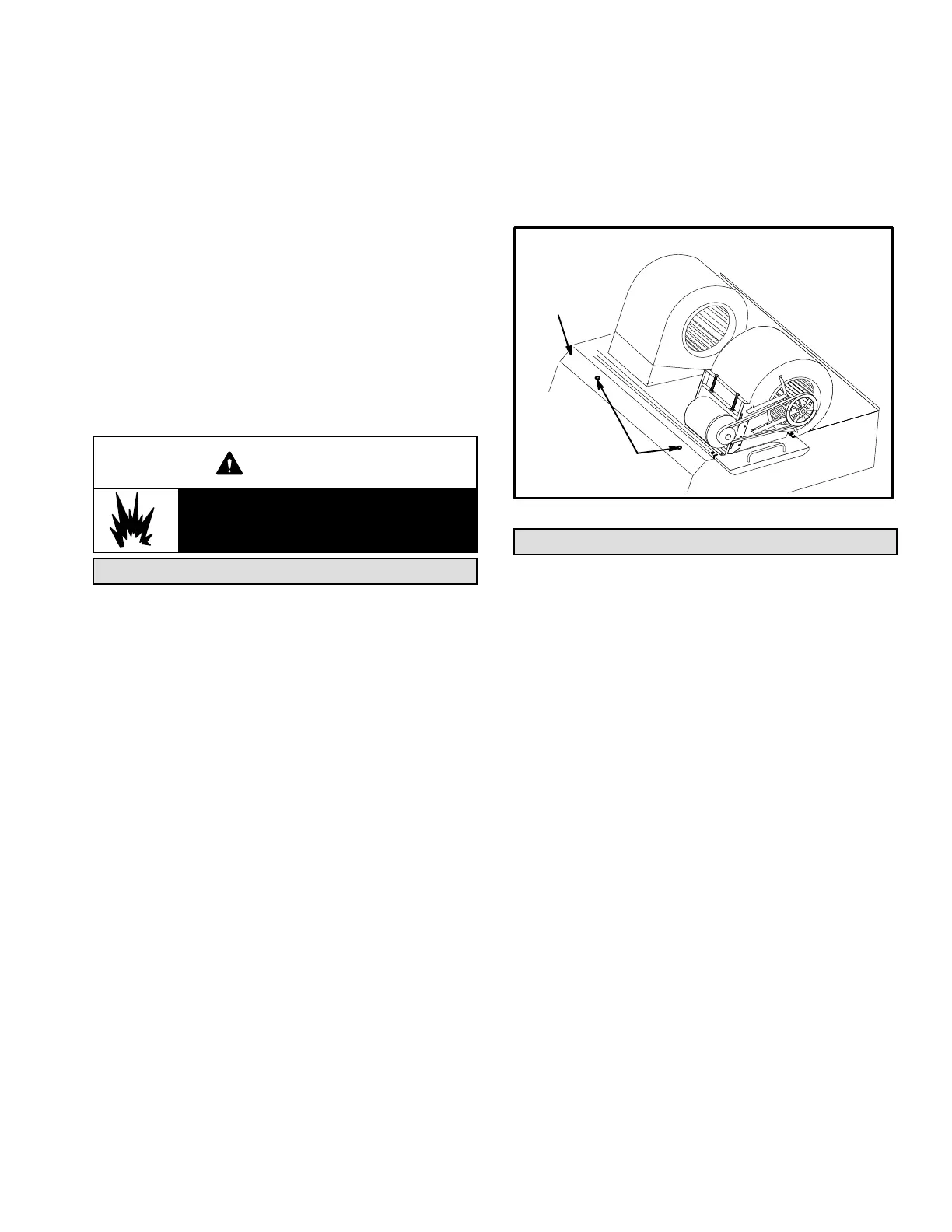

B-Limit Controls

Limit controls are factory-set and are not adjustable. Two

limits are located on the drip shield in the blower

compartment. See figure 18.

C-Heating Adjustment

Main burners are factory-set and do not require adjustment.

The following manifold pressures are listed on the gas valve.

Natural Gas Units - Low Fire - 1.6” w.c.

(not adjustable)

Natural Gas Units - High Fire - 3.7” w.c.

LP Gas Units - Low Fire - 5.5” w.c.

(not adjustable)

LP Gas Units - High Fire - 10.5” w.c.

LIMIT LOCATION

FIGURE 18

LIMITS

DRIP

SHIELD

Heating Start-Up (LHT)

Note - L1 & L2 reversing valves are de-energized with a

heating demand. The heat pump will heat only, not cool.

1- Set thermostat or temperature control device to

initiate a first-stage heating demand.

2- A first-stage heating demand (W1) will energize

compressors 1 and 2, the outdoor fans, and blower.

Note - W1 will also energize optional factory- or

field-installed electric heat during defrost to maintain

discharge air temperature.

3- A second-stage heating demand (W2) will energize

optional electric heat.

Loading...

Loading...