11

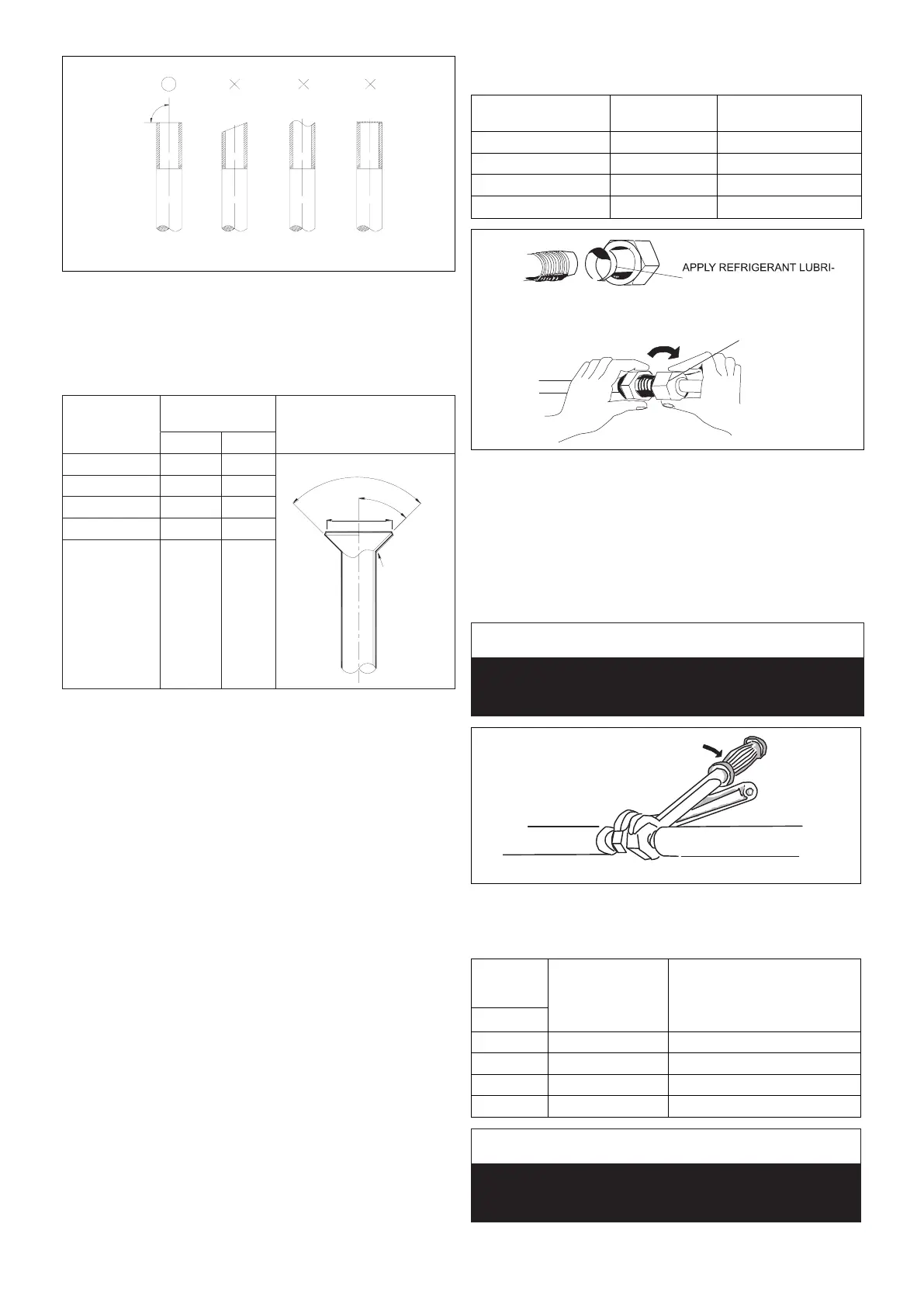

Figure 23. Cutting Piping

5. Insulate the copper piping.

6. Insert a are nut onto each pipe before aring.

7. Use “Table 2. Flaring Pipe” to properly are the pipe.

Table 2. Flaring Pipe

Pipe Diameter

Flare Dimension

A (mm)

Flare Shape

Min Max

1/4” 8.3 8.7

R0.4~0.8

A

45

°

90°

4

-

+

3/8” 12.0 12.4

1/2” 15.4 15.8

5/8” 18.6 19.1

3/4” (22.9) 22.9 23.3

8. After aring the pipe, temporarily sealed pipe ends

with adhesive tape to avoid contaminants from

entering the pipes.

9. The seal on the unit refrigerant piping connections

should remain in place until the last possible moment.

This will prevent dust or water from getting into the

refrigerant piping before it is connected.

10. CAREFULLY adjust refrigerant piping connections to

suit the application.

11. Slowly loosen one of the are nuts to release the

factory nitrogen charge from the indoor units only.

12. Remove the are nuts from the connections on the

unit and discard the seal from each of the piping

connections.

13. Slide the are nuts onto the ends of the eld-provided

refrigerant piping before using a suitable aring tool to

are the end of the copper pipe.

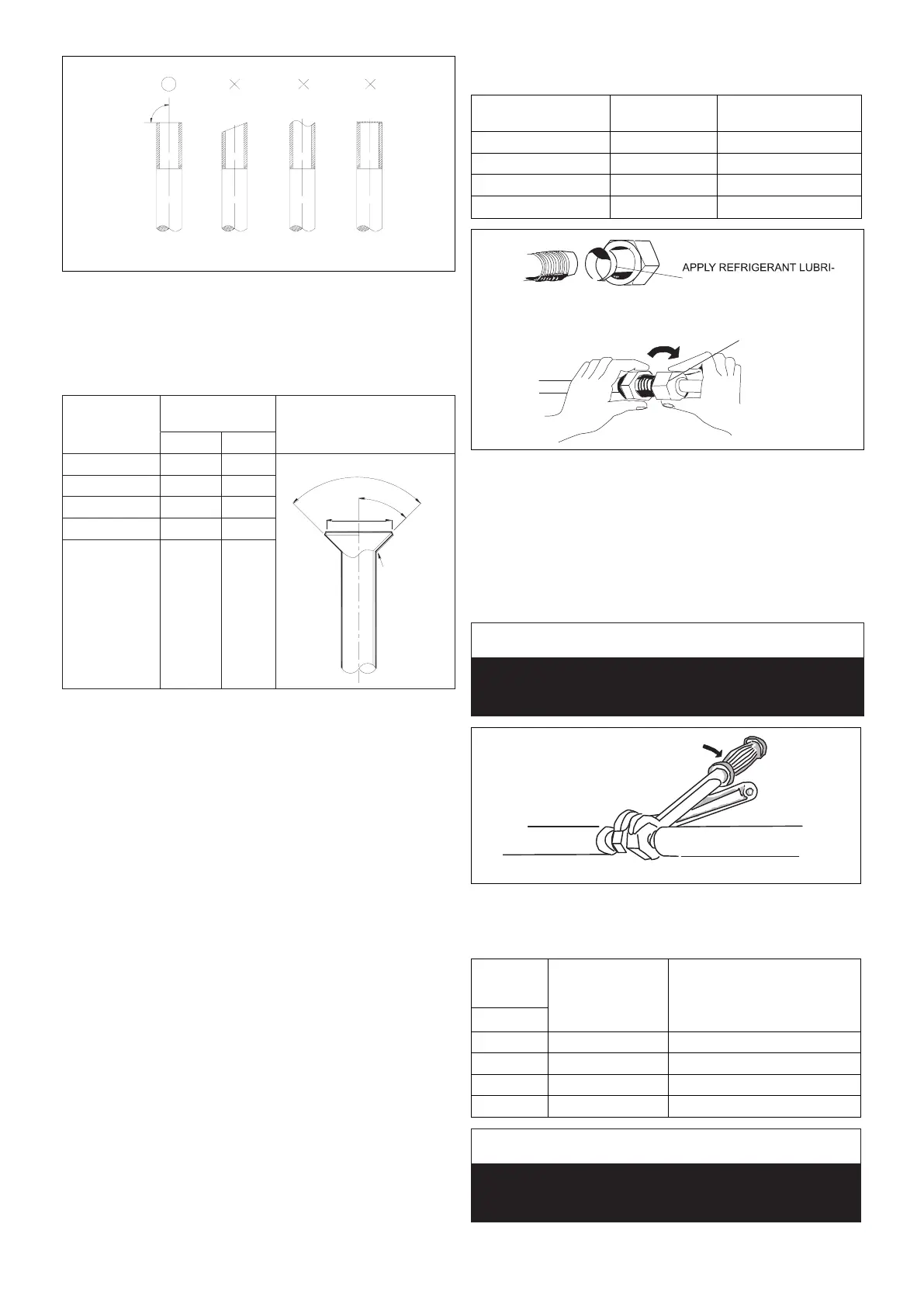

14. Apply recommended HFC-410A refrigerant lubricant

to the outside of the ared refrigerant lines.

15. Align the threaded connections with the

ared refrigerant lines. Tighten the are nuts

lightly at rst to obtain a smooth match as

illustrated in “Figure 24. Making Connections

(Male to Female Connection)”.

Table 3. Refrigerant Piping and Indoor Unit

Connection Sizes

Size

(Btuh)

Liquid Line

in.

Suction Line

in.

9K 1/4 3/8

12K 1/4 1/2

18K 1/4 1/2

24K

3/8 5/8

A

B

CANT ON THE OUTSIDE OF

THE FLARE

MALE FLARE

CONNECTION

Figure 24. Making Connections

(Male to Female Connection)

16. Once snug, continue another half-turn on each nut

which should create a leak-free joint. A torque wrench

may be used to tighten are nuts using “Table 4. Flare

Nut Torque Recommendations”.

17. After refrigerant piping has been installed and checked

for leaks, apply insulation over all ared connections.

IMPORTANT

Always use two wrenches when tightening are nuts to

avoid twisting refrigerant piping. DO NOT over-tighten

are nuts.

TORQUE WRENCH

TO INDOOR

UNIT

TO OUTDOOR UNIT

BACKUP

WRENCH

Figure 25. Tighten Flare Nut

Table 4. Flare Nut Torque Recommendations

Outside

Diameter

Recommended

Torque

No torque wrench available

Finger tighten and use an

appropriately sized wrench to

turn an additional:

Inches

1/4 15 ft.-lb. (20 N) 1/4 turn

3/8 26 ft.-lb. (35 N) 1/2 turn

1/2 41 ft.-lb. (56 N) 7/8 turn

5/8 48 ft.-lb. (65 N) 1 full turn

IMPORTANT

Do not allow for excess length of line sets to be left

rolled up as part of the required, or in general. This will

also cause additional performance issues.

Loading...

Loading...