Page 16

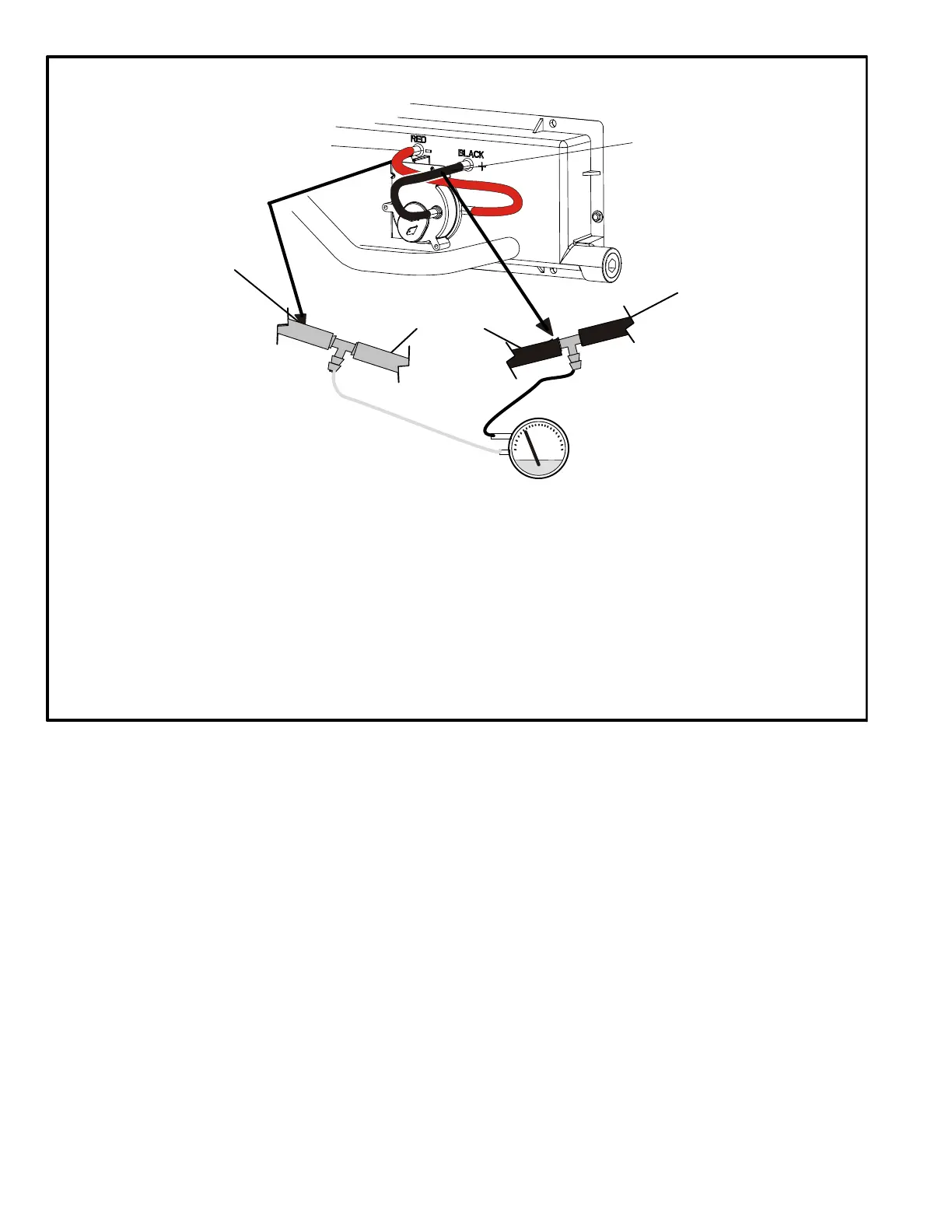

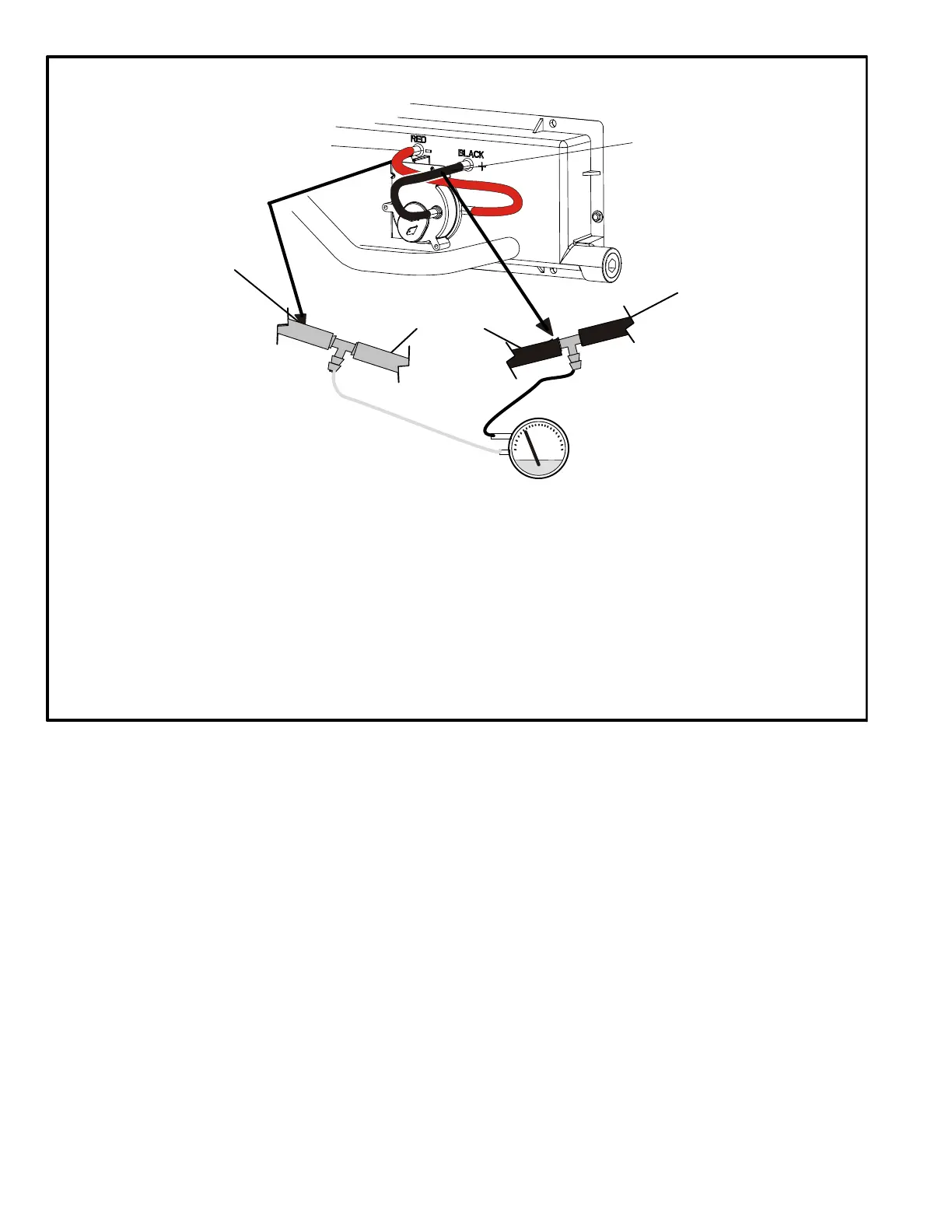

To Cold End Header Box

Field Provided Tubing

To Pressure Switch

To Cold End Header Box

FIGURE 11

1 - Remove thermostat demand and allow unit to

cycle off.

2 - Install a tee in the negative (-) line (red and black tubing

or red tubing) and a tee in the positive (+) line (black

tubing) running from the pressure switch to the cold

end header box.

3 - Install a manometer with hose from the negative (-)

side of the manometer to the tee installed in the

negative (-) line and with hose from the positive (+)

side of the manometer to the tee in the positive (+)

line.

NOTE - Both sides of the cold end header box are nega

tive. However the (+) port reads less negative pressure

than the (-) port.

4 - Operate unit and observe manometer reading.

Readings will change as heat exchanger warms.

a. Take one reading immediately after start‐up.

b. Take a second reading after unit has reached

steady state (approximately 5 minutes). This will be

the pressure differential.

The pressure differential should be greater

than those listed in table 6.

5 - Remove thermostat demand and allow to cycle off.

6 - Remove manometer and tee's. Reinstall combustion

air sensing hoses to the pressure switch.

Measuring Pressure Differential

Black Tubing

(positive +)

Red and Black Tubing

or Red Tubing

(negative -)

“+”

High

“-”

Low

Loading...

Loading...