Page 38

NOTE - Cold end header box drain plugs are factory in

stalled. Check the unused plug for tightness to prevent

leakage.

3 - Install the cap over the clean out opening at the base

of the trap. Secure with clamp. See figure 53.

4 - Install drain trap using appropriate PVC fittings, glue

all joints. Glue the provided drain trap as shown in fig

ure 53. Route the condensate line to an open drain.

Condensate line must maintain a 1/4” downward slope

from the furnace to the drain.

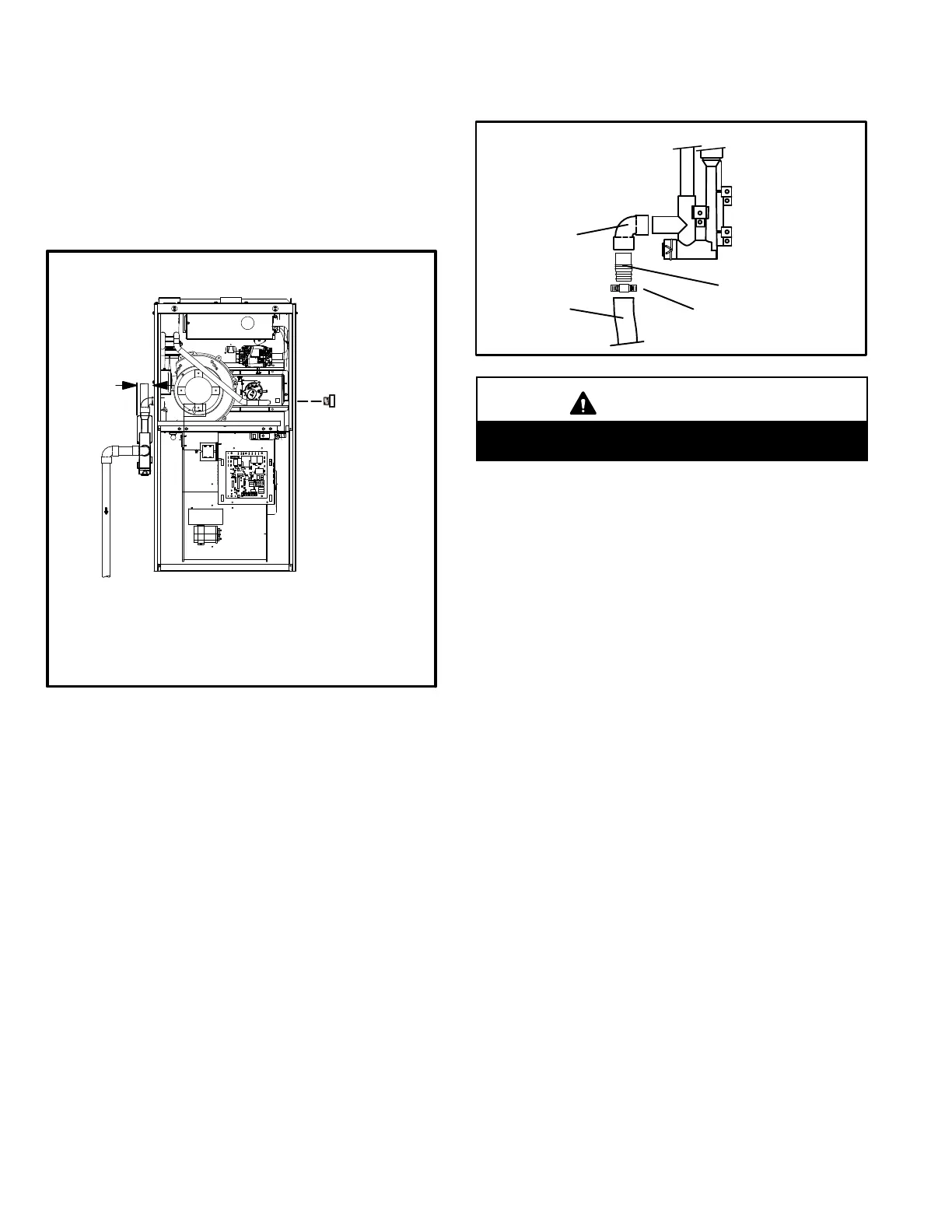

FIGURE 45

CONDENSATE TRAP AND PLUG LOCATIONS

(Unit shown in upflow position)

NOTE - In upflow applications where side return

air filter is installed on same side as the conden

sate trap, filter rack must be installed beyond

condensate trap or trap must be re-located to

avoid interference.

Trap

(same on

right side)

Plug

(same on left side)

1-1/2 in.

5 - Figures 48 and 50 show the furnace and evaporator

coil using a separate drain. If necessary the conden

sate line from the furnace and evaporator coil can

drain together. See figures 49, 51 and 52.

Upflow furnace (figure 51) - In upflow furnace applica

tions the field provided vent must be a minimum 1” to a

maximum 2” length above the condensate drain outlet

connection. Any length above 2” may result in a flood

ed heat exchanger if the combined primary drain line

were to become restricted.

Horizontal furnace (figure 52) - In horizontal furnace

applications the field provided vent must be a mini

mum 4” to a maximum 5” length above the condensate

drain outlet connection. Any length above 5” may re

sult in a flooded heat exchanger if the combined pri

mary drain line were to become restricted.

NOTE - In horizontal applications it is recommended to

install a secondary drain pan underneath the unit and

trap assembly.

NOTE - Appropriately sized tubing and barbed fitting may

be used for condensate drain. Attach to the drain on the

trap using a hose clamp. See figure 46.

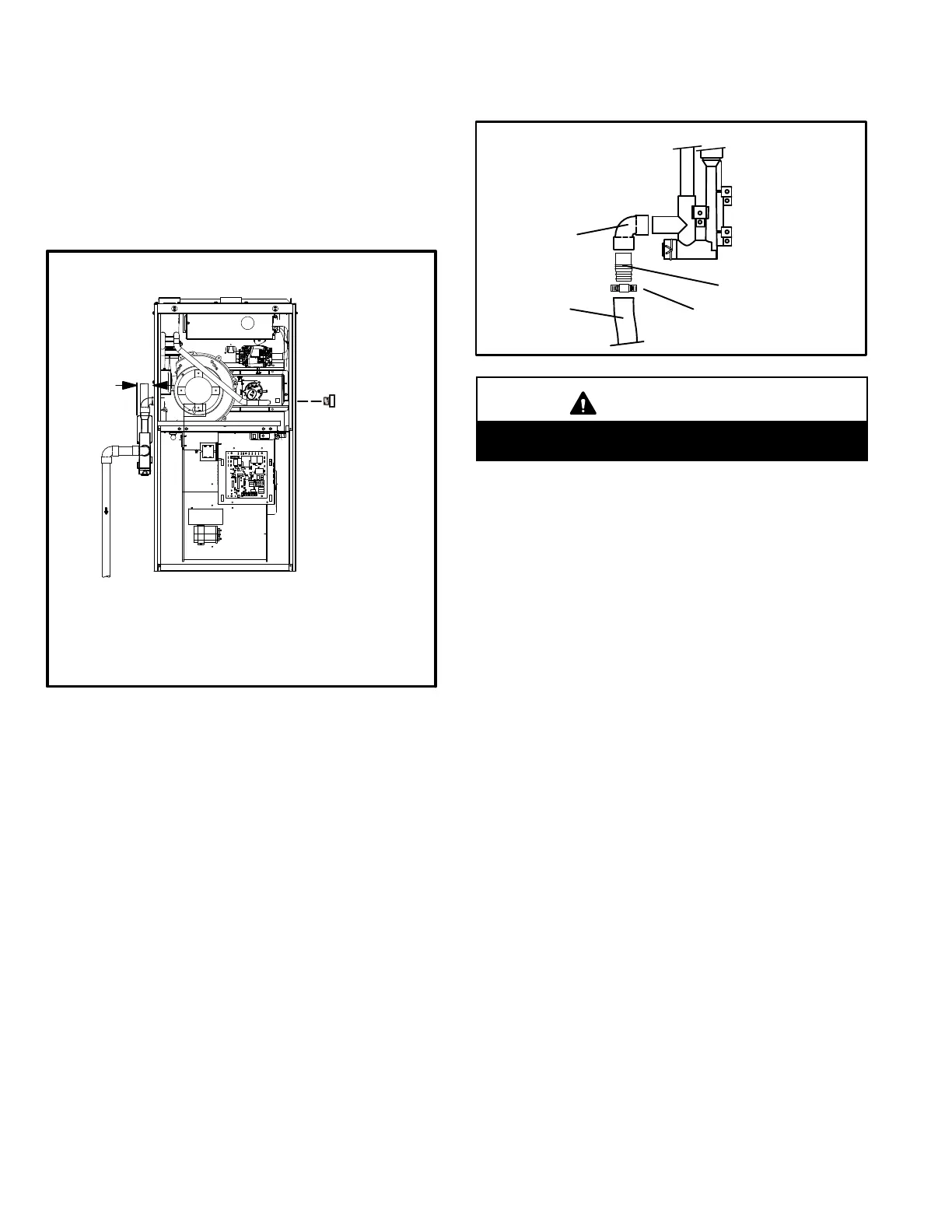

FIGURE 46

Tubing

Hose Clamp

Barbed Fitting

Field Provided Drain Components

Elbow

CAUTION

Do not use copper tubing or existing copper conden

sate lines for drain line.

6 - If unit will be started immediately upon completion of in

stallation, prime trap per procedure outlined in Unit Start-

Up section.

Condensate line must slope downward away from the

trap to drain. If drain level is above condensate trap,

condensate pump must be used. Condensate drain

line should be routed within the conditioned space to

avoid freezing of condensate and blockage of drain

line. If this is not possible, a heat cable kit may be used

on the condensate trap and line. Heating cable kit is

available from Lennox in various lengths; 6 ft. (1.8m) -

kit no. 26K68 and 24 ft. (7.3m) - kit no. 26K69.

Loading...

Loading...