Page 12

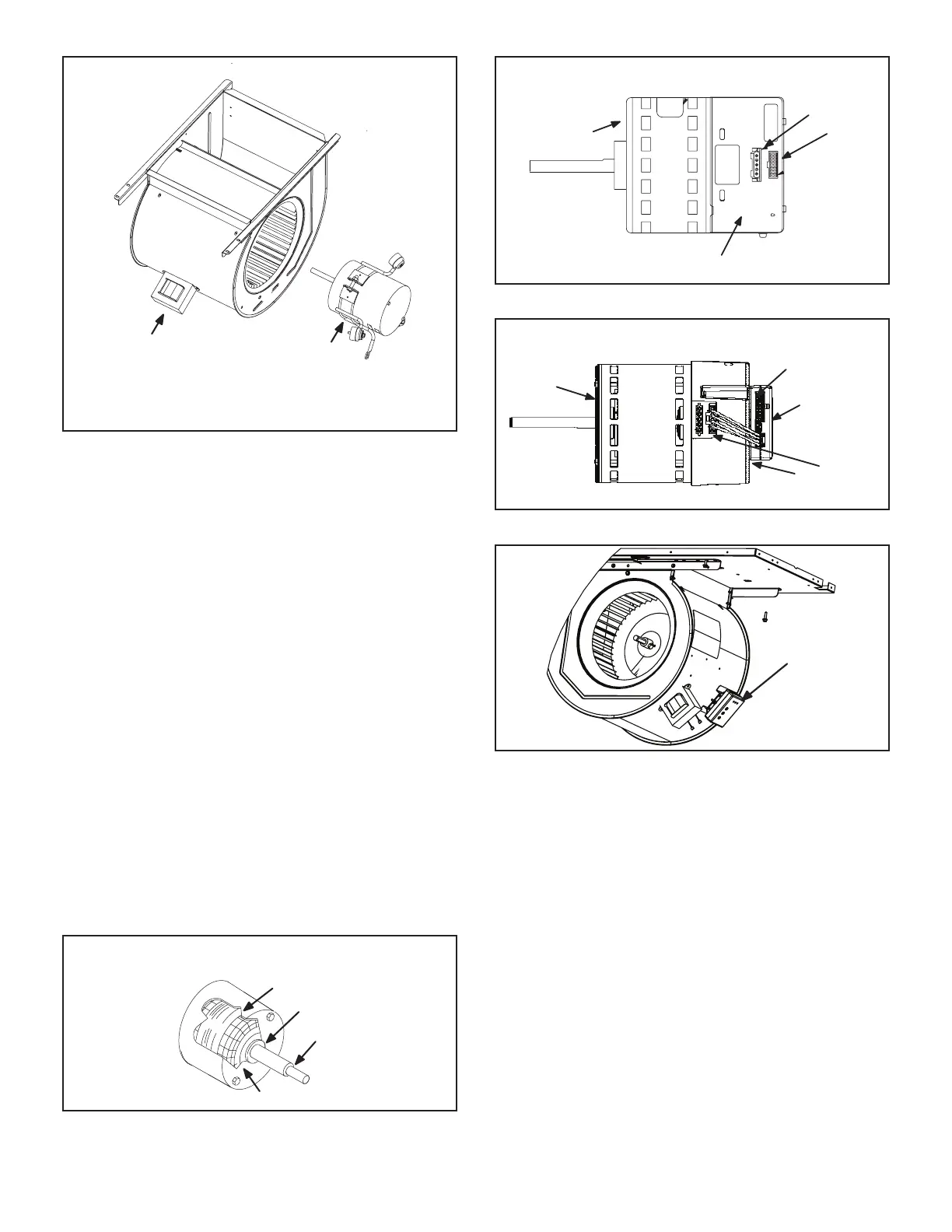

Power Choke

(5 Ton Only)

Blower Motor

(B3)

To Remove Blower From Unit: Remove Bolts and

Wiring Jackplugs. Then Slide Out Front of Unit.

FIGURE 4

Blower Motor (B3)

Blower motors are manufactured by GenTeq and Nidec.

See FIGURE 6 and FIGURE 7. Motors operate the same

and are only dierent in physical appearance. They are

both three-phase, electronically controlled DC brushless

motors (controller converts single-phase AC to three-

phase DC), with a permanent magnet type rotor. Because

these motors have a permanent magnet rotor it does not

need brushes like conventional DC motors.

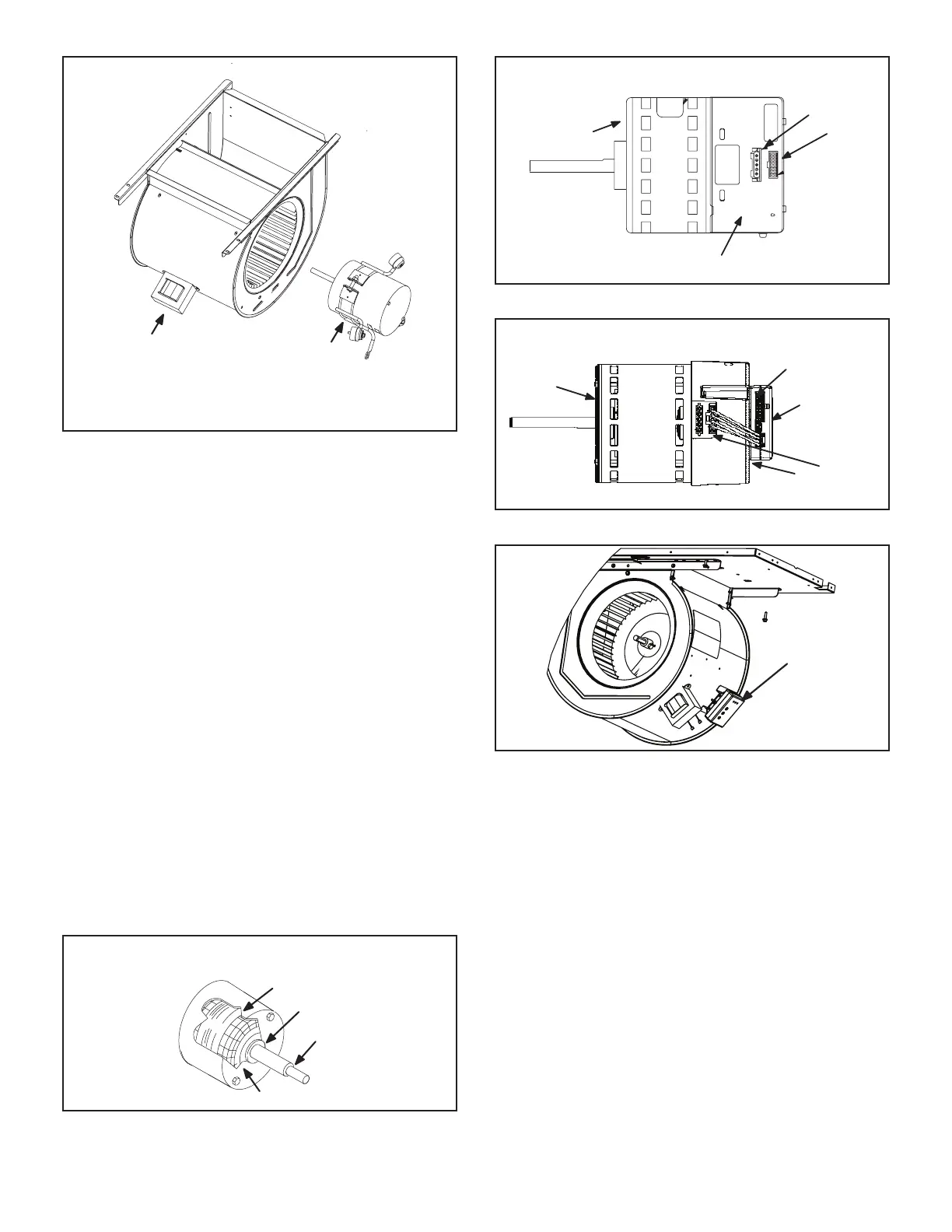

Internal components for both manufactured motors are

similarand shown in FIGURE 5. The stator windings are

split into three poles which are electrically connected to

the controller. This arrangement allows motor windings to

turn on and o in sequence by the controller.

A solid-state controller is attached to the motor. The con-

troller is primarily an AC to DC converter. Converted DC

power is used to drive the motor. The controller contains a

microprocessor which monitors varying conditions inside

the motor (such as motor workload). The controller on the

NIDEC / Emerson motor includes the 16X4W control with

three LED’s PW, RX and TX located on the face for trou-

bleshooting. FIGURE 7 shows the location of the 16X4W

and TABLE 5 the LED codes. The 16X4W may be located

on the indoor blower housing on some models (FIGURE

8).

STATOR

(WINDINGS)

OUTPUT

SHAFT

BEARING

FIGURE 5

MOTOR

CONTROLLER

J49

J48

FIGURE 6

NIDEC BLOWER MOTOR B3

MOTOR

CONTROLLER

16X4W

(May located

on the blower

housing)

J48

J49

FIGURE 7

FIGURE 8

The controller uses sensing devices to sense what posi-

tion the rotor is in at any given time. By sensing the posi-

tion of the rotor and then switching the motor windings on

and o in sequence, the rotor shaft turns the blower.

All blower motors use single phase power. An external run

capacitor is not used. The motor uses permanently lubri-

cated ball-type bearings.

Internal Operation

Each time the controller switches a stator winding (FIG-

URE 5) on and o, it is called a “pulse.” The length of

time each pulse stays on is called the “pulse width.” By

varying the pulse width (FIGURE 11), the controller varies

motor speed (called “pulsewidth modulation”). This allows

for precise control of motor speed and allows the motor to

compensate for varying load conditions as sensed by the

controller. In this case, the controller monitors the static

workload on the motor and varies motor rpm in order to

maintain constant airow (cfm).

Loading...

Loading...