Page 10

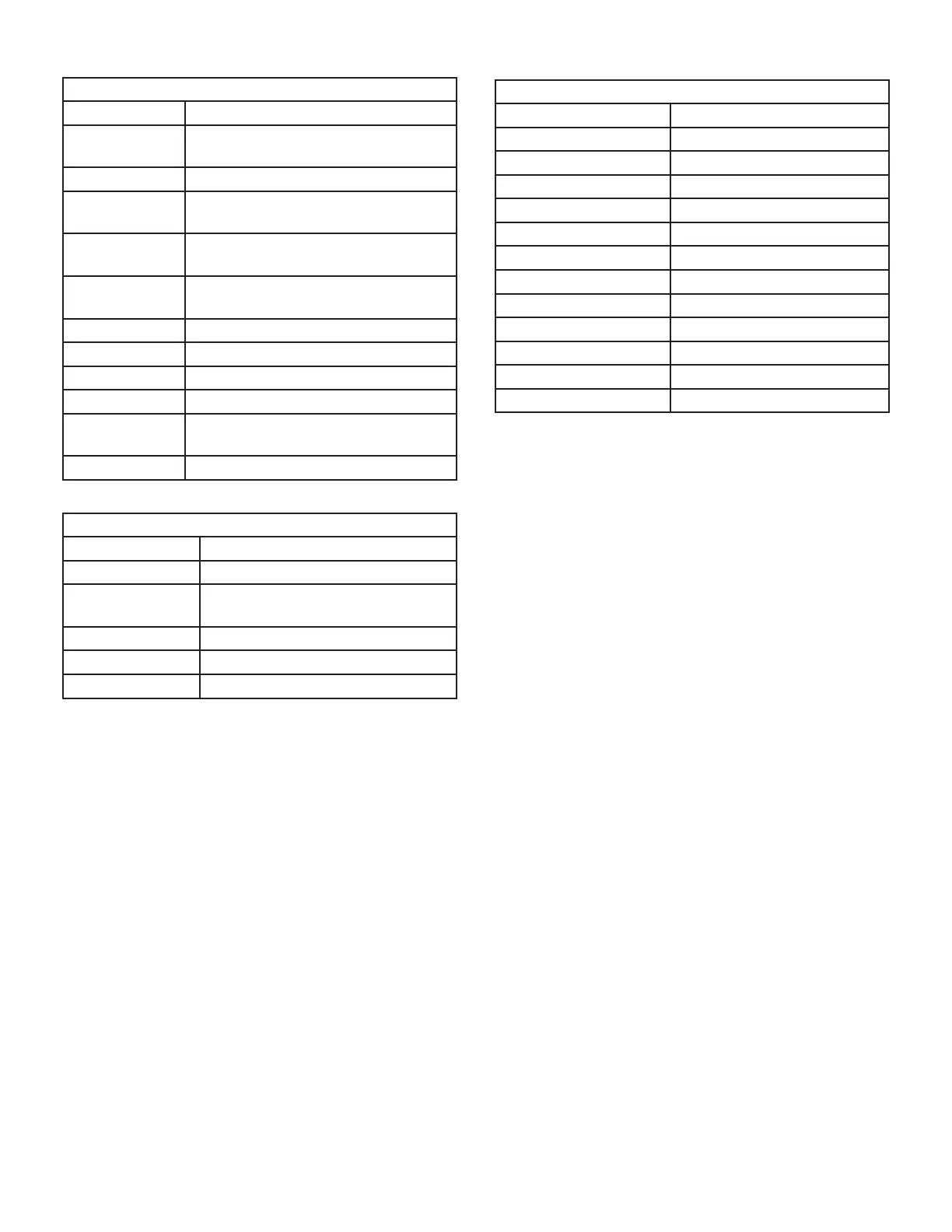

TABLE 2

Diagnostic Codes Red LED

LED Status Description

LED O

No power to control or control har-

ware fault detected.

LED On Normal operation.

1 Flash

Flame present with gas vavle de-en-

ergized.

2 Flashes

Pressure switch closed with combus-

tion air inducer de-energized.

3 Flashes

Low-re pressure, rollout or limit

switch open.

4 Flashes Primary limit switch open.

5 Flashes Not used

6 Flashes Pressure switch cycle lockout.

7 Flashes Lockout, burners fail to light.

8 Flashes

Lockout, buners lost ame too many

times.

9 Flashes Line voltage polarity incorrect.

TABLE 3

Control 5 Pin Terminal Designation

PIN # Function

1 Ignitor (Hot)

2 Combustion Air Inducer High

Speed

3 Combustion Air Inducer Low Speed

4 Combustion Air Inducer Neutral

5 Ignitor Neutral

Airow Adjustments

Cooling Mode

The units are factory set for the highest airow for each

model. Adjustments can be made to the cooling airow by

repositioning the jumper plug marked COOL – A, B, C, D

(see FIGURE 3). To determine what CFM the motor is de-

livering at any time, count the number of times the amber

LED on the control board ashes. Each ash signies 100

CFM; count the ashes and multiply by 100 to determine

the actual CFM delivered (for example: 5 ashes x 100 =

500 CFM).

Fan on / o delay

On a call for heat there is a 30 second fan on delay after

igntion.When the call for heat is satised, the gas valve

and combustion air blower shut down. The circulating air

blower continues to run for selected blower o delay time

(60/90/120/180 sec) before ramping down and shutting

o. The fan on delay is 30 seconds and not adjustabe.

NOTE - The fan o delay on ML296-55 and earlier units is

factory set at 120 seconds and NON- ADJUSTABLE.

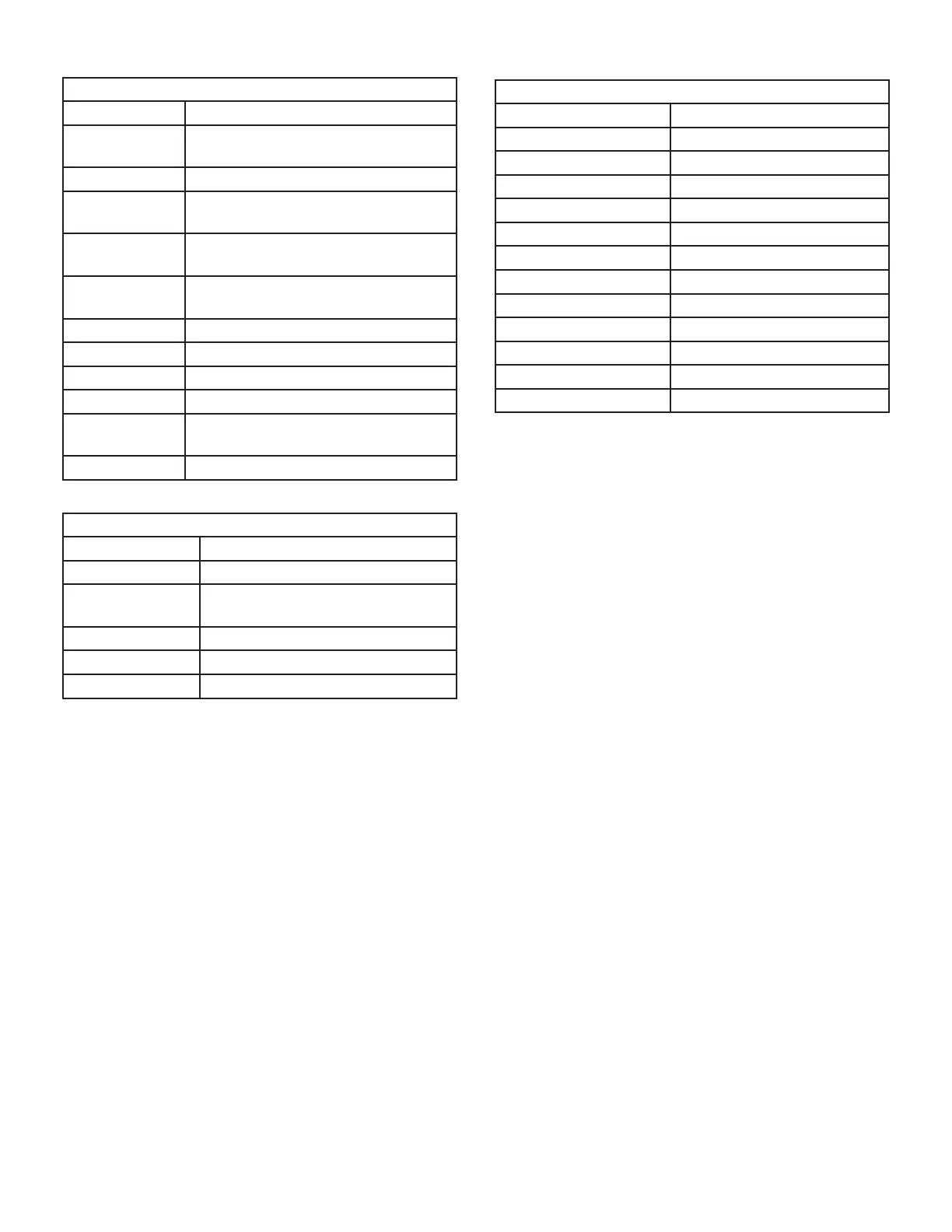

TABLE 4

12 Pin Terminal Designation

Pin # Function

1 Gas Valve Second Stage

2 Second Stage Prove Switch

3 Rollout Switch In

4 Ground

5 24V Hot

6 Primary Limit In

7 Gas Valve First Stage

8 Gas Valve Common

9 24V Neutral

10 Ground

11 Rollout Switch Out

12 First Stage Prove Switch

Heating Mode

These units are factory set to run at the middle of the heat-

ing rise range as shown on the unit rating plate. If higher

or lower rise is desired, reposition the jumper plug marked

HEAT - A, B, C, D (see FIGURE 3) . To determine what

CFM the motor is delivering at any time, count the number

of times the amber LED on the control board ashes. Each

ash signies 100 CFM; count the ashes and multiply by

100 to determine the actual CFM delivered (for example:

5 ashes x 100= 500.

Adjust Tap

Airow amounts may be increased or decreased by 10%

by moving the ADJUST jumper plug (see Figure 3) from

the NORM position to the (+) or (-) position. Changes to

the ADJUST tap will aect both cooling and heating air-

ows. The TEST position on the ADJUST tap is not used.

Continuous Blower Operation

The comfort level of the living space can be enhanced

when using this feature by allowing continuous circulation

of air between calls for cooling or heating. The circulation

of air occurs at half the full cooling airow rate.

To engage the continuous blower operation, place the fan

switch on the thermostat into the ON position. A call for fan

from the thermostat closes R to G on the ignition control

board. The control waits for a 1 second thermostat delay

before responding to the call for fan by ramping the circu-

lating blower up to 50% of the cooling speed. When the

call for continuous fan is satised, the control immediately

ramps down the circulating blower.

Loading...

Loading...