Page 47

V-TYPICAL OPERATING CHARACTERISTICS

A-Blower Operation and Adjustment

1 - Blower operation is dependent on thermostat control

system.

2 - Generally, blower operation is set at thermostat

subbase fan switch. With fan switch in ON position,

blower operates continuously. With fan switch in

AUTO position, blower cycles with demand or runs

continuously while heating or cooling circuit cycles.

3 - Depending on the type of indoor thermostat, blower

and entire unit will be o when the system switch is

in OFF position.

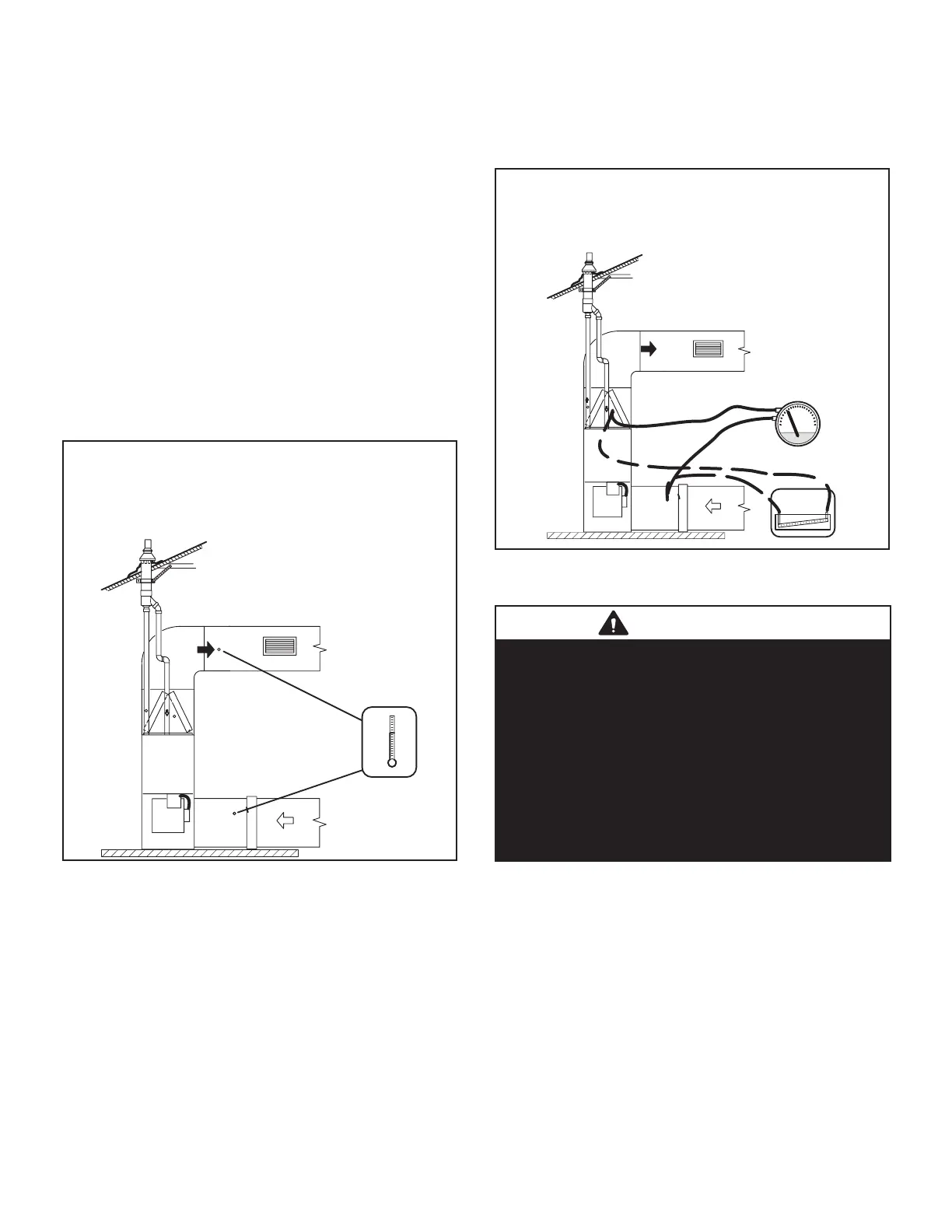

B-Temperature Rise (FIGURE 53)

Temperature rise for ML296UHV units depends on unit in-

put, blower speed, blower horsepower and static pressure

as marked on the unit rating plate. The blower speed must

be set for unit operation within the range of “TEMP. RISE

°F” listed on the unit rating plate.

°

TEMPERATURE RISE

Supply Duct Temperature ________

Return Duct Temperature

_

_____

Temperature Rise = ________

SUPPLY

AIR

Temperatures

RETURN AIR

FIGURE 53

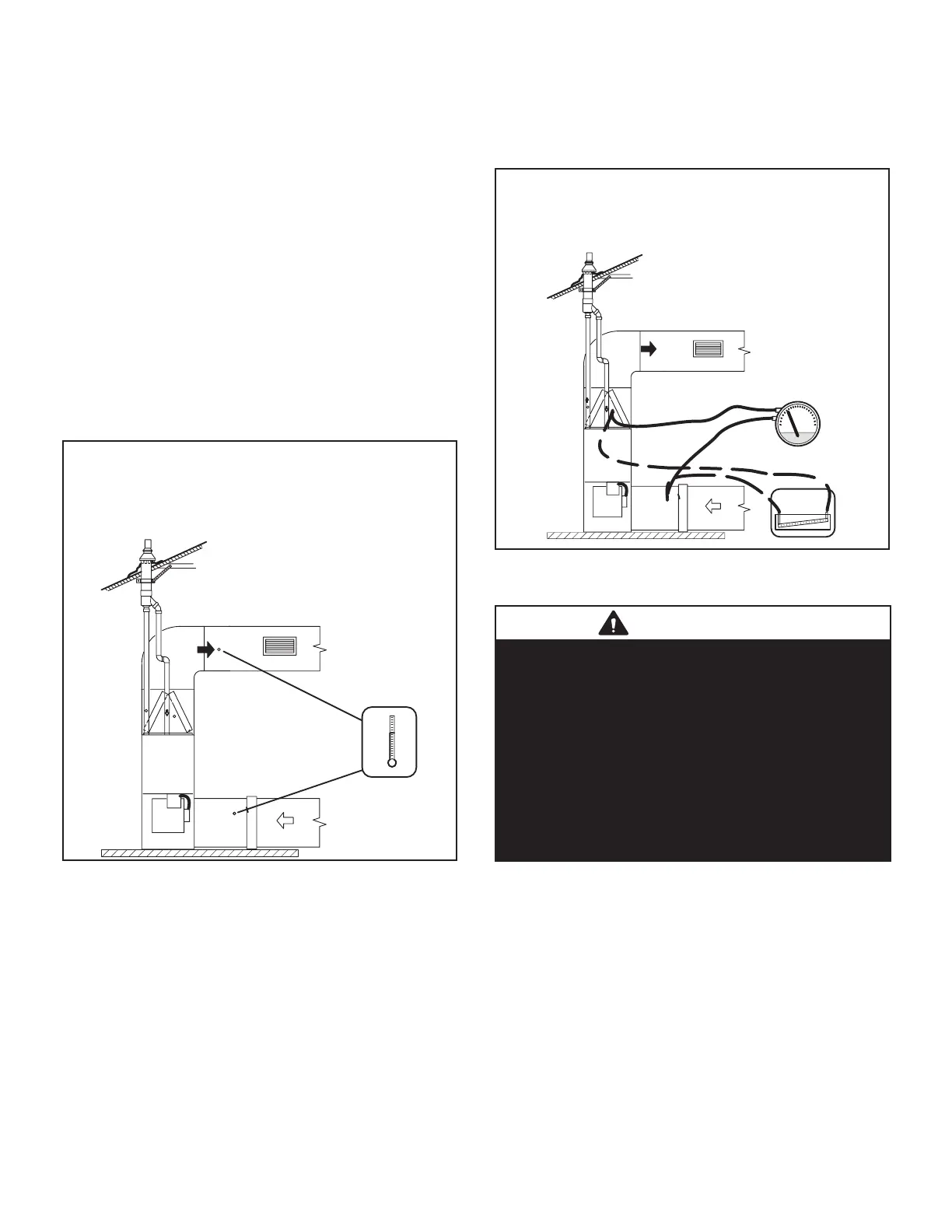

C-External Static Pressure

1 - Tap locations shown in FIGURE 54.

2 - Punch a 1/4” diameter hole in supply and return

air plenums. Insert manometer hose ush with

inside edge of hole or insulation. Seal around the

hose with permagum. Connect the zero end of the

manometer to the discharge (supply) side of the

system. On ducted systems, connect the other end

of manometer to the return duct as above.

3 - With only the blower motor running and the

evaporator coil dry, observe the manometer reading.

Adjust blower motor speed to deliver the air desired

according to the job requirements.

For heating speed (second stage heat speed)

external static pressure drop must not be more than

0.8” W.C. For cooling speed (second stage cool

speed) external static pressure drop must not be

more than 1.0” W.C.

4 - Seal the hole when the check is complete.

Supply Duct Static ________

Return Duct Static + _____

Total Duct Static = ________ (dry coil)

Duct Static

or

Supply Air

Return Air

FIGURE 54

VI-MAINTENANCE

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could

result in dangerous operation, serious injury, death

or property damage.

Improper servicing could result in dangerous

operation, serious injury, death, or property damage.

Before servicing, disconnect all electrical power to

furnace.

When servicing controls, label all wires prior

to disconnecting. Take care to reconnect wires

correctly. Verify proper operation after servicing.

At the beginning of each heating season, system should

be checked as follows by a qualied service technician:

Blower

Check the blower wheel for debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

Filters

All air lters are installed external to the unit. Filters should

be inspected monthly. Clean or replace the lters when

necessary to ensure proper furnace operation. TABLE 23

lists recommended lter sizes.

Loading...

Loading...