Remove the cap to access the screw for input

adjustment (Figure 13 Pressure Regulator). Turn

regulator-adjusting screw IN to increase pressure,

OUT to decrease pressure. Replace the cap. Measure

the manifold pressure.

For Natural gas, best results are obtained with a

manifold pressure of 3.2" to 3.5"w.c. For units that have

been converted to LP (Propane) gases, a manifold

pressure of 10"w.c. is necessary. After proper

adjustment, turn OFF gas, replace manifold pressure tap

pipe plug and turn ON gas.

At higher altitudes and varying heating valves,

manifold pressure or orifice changes maybe

required. Consult Tables 7 and 8 for appropriate

values. Failure to follow this warning could lead to

a hazardous furnace operating condition and result

in serious bodily injury or loss of life.

Determining Furnace Input - Natural Gas ONLY:

NOTE: Louvered access door of furnace must be in

place when checking gas input.

1. Turn OFF all other gas appliances (except for pilot

burners) served by the same gas meter.

2. With furnace operating in full heat cycle, note how

many seconds it takes for one full revolution of the

smallest dial on the meter. Typically, this will be a

1/2 - or - 1 - cubic foot test dial.

3. Using the number of seconds for one revolution and

the size of the meter dial, determine the cubic foot

per hour of gas flow by using the formula provided

below or Table 5.

Cubic Ft/Hr =

Number of Dial Revolutions x Cubic Foot/Revolution x 3600

Time (in seconds) Required for Number of Timed Revolutions

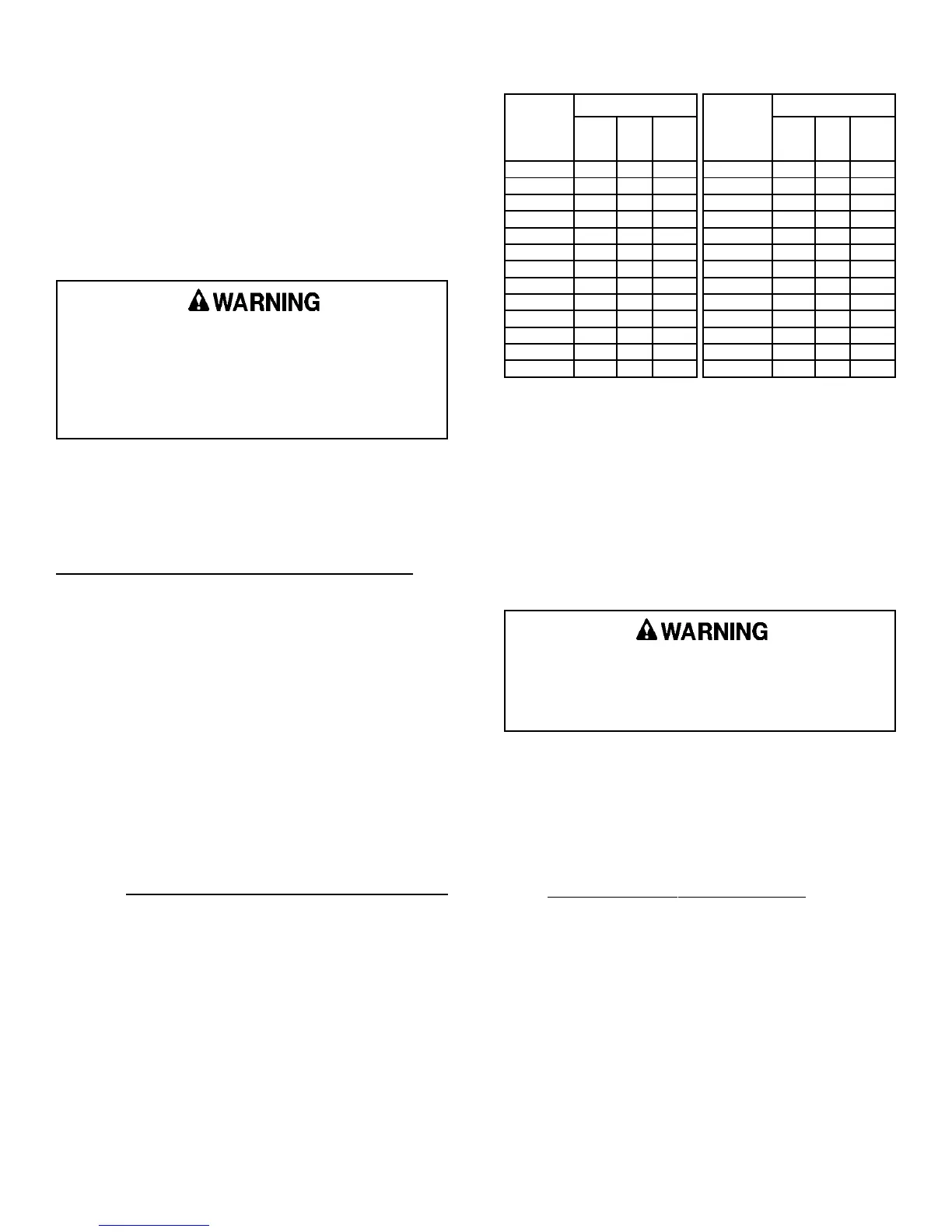

TABLE 5

Gas Rate (Cubic Feet per Hour)

Seconds for

One

Revolution

TEST DIAL

1/2

Cubic

Feet

1

Cubic

Foot

2

Cubic

Feet

10 160 360 720

12 150 300 600

14 129 257 514

16 113 225 450

18 100 200 400

20 90 180 360

22 82 164 325

24 75 150 300

26 69 138 276

28 64 129 258

30 60 120 240

32 56 113 226

34 53 106 212

Seconds for

One

Revolution

TEST DIAL

1/2

Cubic

Feet

1

Cubic

Foot

2

Cubic

Feet

36 50 100 200

38 47 95 190

40 45 90 180

42 43 86 172

44 41 82 164

46 39 78 156

48 37 75 150

50 36 72 144

52 35 69 138

54 34 67 134

56 32 64 128

58 31 62 124

60 30 60 120

4. Calculate the furnace input using the following

formula:

BTUH = Cubic Ft/Hr x BTU/Cubic Foot

The local gas supplier should be able to provide the

heating value of the gas, in BTU/cubic foot. If a

specific value is not available, use 1000 BTU/cubic

foot for Natural gas or 2500 BTU/cubic foot for

Propane (LP).

Furnace input should be maintained within ± 2% of

the value on the rating plate or appropriate altitude

derate. Adjust manifold pressure or change main

orifices size if required.

5. Calculate the unit's actual input rate.

Example: If the heating value of the natural gas is 1015

Btu/cu. and it takes 60 seconds to burn 2 cu.

ft. of gas then:

Input = 1015 Btu/cu. ft. X 1 rev X 2 cu. ft./rev. X 3600

60 sec.

Input = 121,800 Btu/hr.

20541501 Issue 0240 Page 19 of 26

Loading...

Loading...