• 14 •

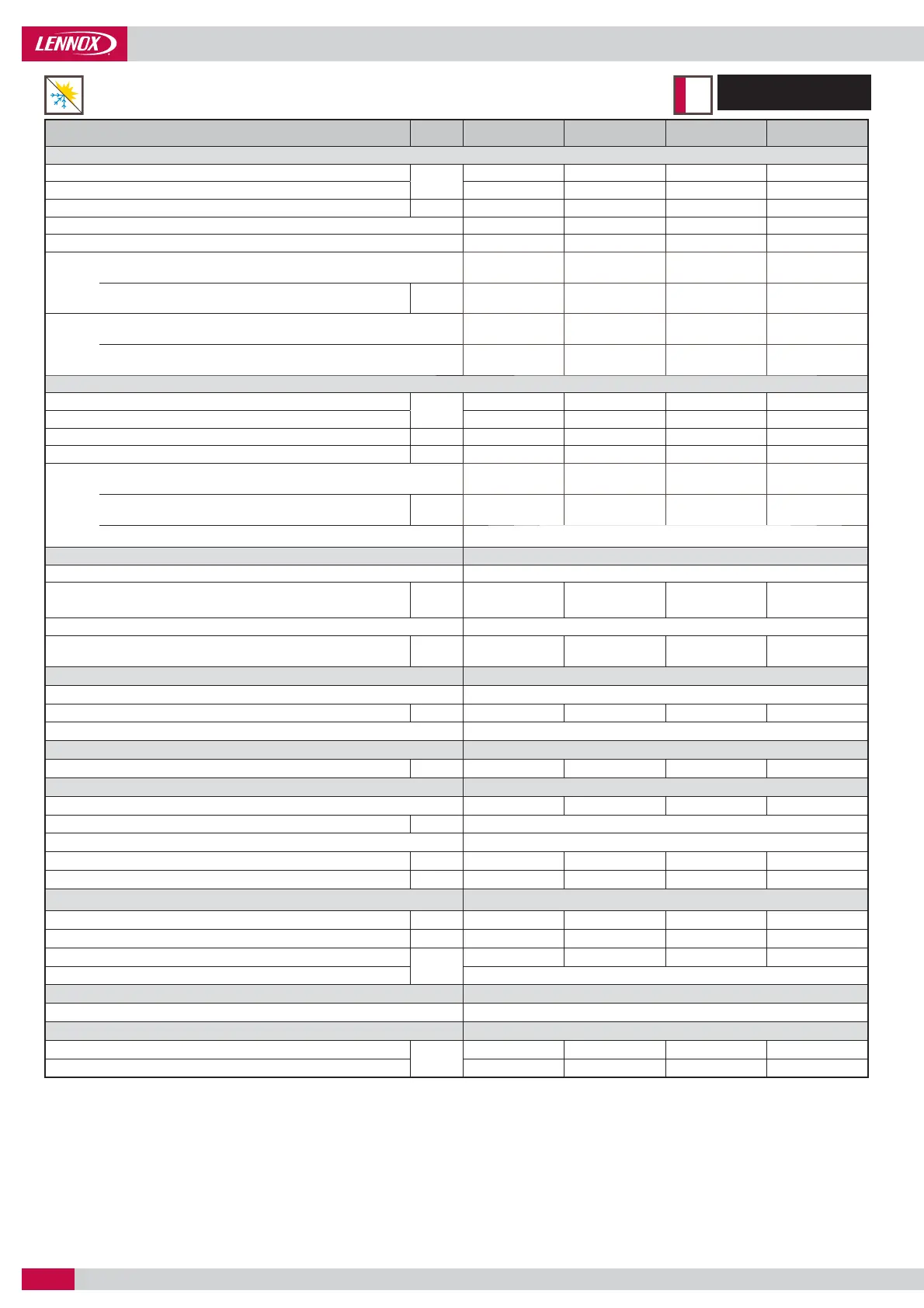

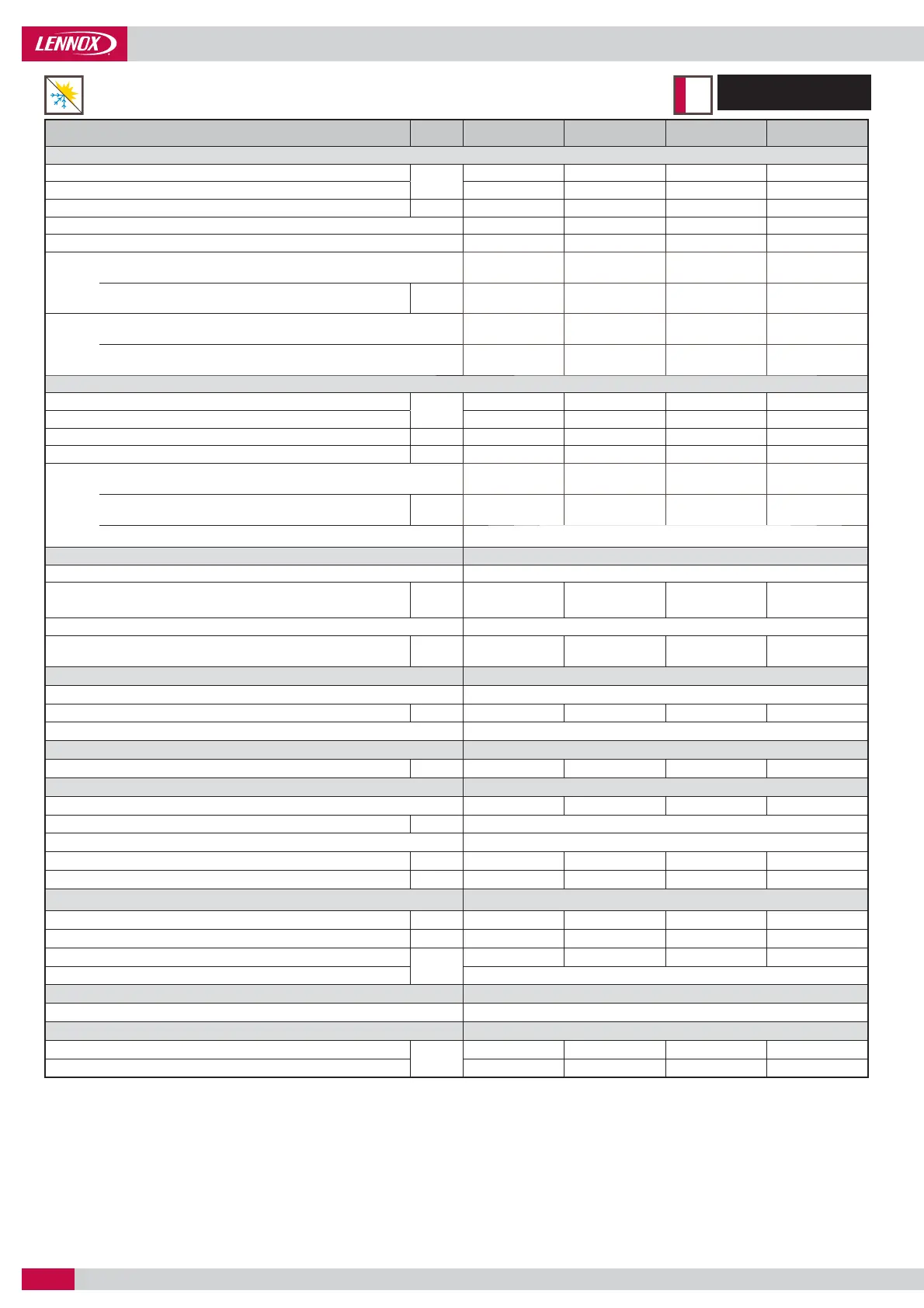

NEOSYS NAH 200 230 270 300

kW

191 217 271 295

73,5 86,7 106,7 117,0

A 127,9 150,7 185,6 203,5

EER

(1)

2,60 2,50 2,54 2,52

ESEER

(2)

4,00 3,76 3,99 3,94

3,93 3,91 3,92 4,00

% 154 154 154 157

5,20 5,04 5,06 5,01

3,15 3,20 3,02 3,09

kW

219 235 291 339

71,7 84,0 104,3 112,7

A 125,9 145,3 172,8 192,5

COP

(3)

3,05 2,80 2,78 3,01

3,44 3,32 3,39 3,45

% 134 130 132 135

A+

4

%

31 - 62 -

81 - 100

34 - 68 -

84 - 100

28 - 57 -

78 - 100

25 - 50 -

75 - 100

(3,2+6,8)

+ (3,2+6,8)

(3,2+6,3)

+ (3,2+6,3)

(6,8+6,3)

+ (6,8+6,3)

(6,3x2)

+ (6,3x2)

2

kg 28 28 40 42

4466

4466

mm 800

m

3

/h 76 000 76 000 114 000 114 000

kW 6,4 6,4 9,6 9,6

m

3

/h 32,9 37,3 46,6 50,8

20 20 23,2 23,2

kPa

36,7 46,4 55,2 44,7

600

4"

400V / III / 50 Hz

A

393,9 446,5 483,3 512,7

166,5 195,8 232,6 262,0

NAH

410AR

Application Guide / NEOSYS-AGU-1801-E

Cooling mode

Cooling capacity

(1)

Total absorbed power

(1)

Full load amps

(1)

Seasonal Energy Effi ciency Ratio

(4)

SEER

Seasonal energy effi ciency

(3)

ɳs,c

Seasonal Energy Performance Ratio

(5)

SEPR - High temperature (7°C)

Seasonal Energy Performance Ratio

(6)

SEPR - Medium temperature (-8°C)

Heating mode

Heating capacity

(1)

Power input

(1)

Full load amps

(1)

Seasonal energy effi ciency

(8)

SCOP

Seasonal energy effi ciency

(7)

ɳs,h

Seasonal energy effi ciency class

(9)

Compressors Scroll - Hermetic

Number of compressors

Capacity steps

Oil type MOBIL EAL Arctic 22CC or ICI EMKARATE RL32CF

Oil load per compressor

Refrigeration circuit

Number of circuit

Refrigerant load per circuit (R410A)

Type of expansion valve Thermostatic expansion valve

Condenser Copper tube - Aluminium fi n - Air-cooled

Number of condenser

Fan & Motor Variable speed fans

Number of fans

Diameter

Maximum speed Variable speed - 900 rpm maximum

Nominal air fl ow (100%)

Total motor power input

Evaporator AISI 304 stainless steel plate brazed with copper heat exchanger

Water fl ow

(1)

Water volume

Pressure drop

(1)

Water operating pressure

Hydraulic connections Victaulic

Water inlet/outlet

Electrical data

Starting current

Maximum current

GENERAL DATA

HEAT PUMP

(1) EUROVENT certifi ed data, in accordance with

standard EN14511 :

Water inlet / outlet temperature = 12 °C / 7 °C

Outdoor air temperature = 35 °C.

(2) ESEER following Eurovent calculation method,

in accordance with standard EN14511

(3) Following ecodesign regulation nr

EU 2016/2281 on space cooling, normalized

leaving water temperature at 7 °C, in

accordance with standard EN14825.

(4) SEER in accordance with standard

EN14825.

(5) Following ecodesign regulation nr

EU 2016/2281 on process cooling units,

normalized leaving water temperature at 7°C,

in accordance with standard EN14825.

(6) Following ecodesign regulation nr

EU 2015/1095 on process cooling chillers,

normalized leaving water temperature at

-8°C, in accordance with standard EN14825

(7) SCOP in accordance with standard

EN14825. Heating mode performance is

defi ned for average climate.

(8) Following ecodesign regulation nr

EU 813/2013 on space heaters, normalized

leaving water temperature at 7°C, in

accordance with standard EN14825, average

climate.

(9) Following energy labelling regulation nr

EU 811/2013 on space heaters.

Comfort

applica-

tions

Comfort

applications

Process

applica-

tions

Loading...

Loading...