Page 21

3− Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the com

mon venting system are located and other spaces of

the building. Turn on clothes dryers and any ap

pliances not connected to the common venting sys

tem. Turn on any exhaust fans, such as range hoods

and bathroom exhausts, so they will operate at maxi

mum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

4− Following the lighting instruction on the unit, place the

appliance being inspected in operation. Adjust thermo

stat so appliance will operate continuously.

5− Test for spillage using a draft gauge.

6− After it has been determined that each appliance re

maining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other fuel burning appliance to their previous condi

tion of use.

7− If improper venting is observed during any of the

above tests, the common venting system must be

corrected.

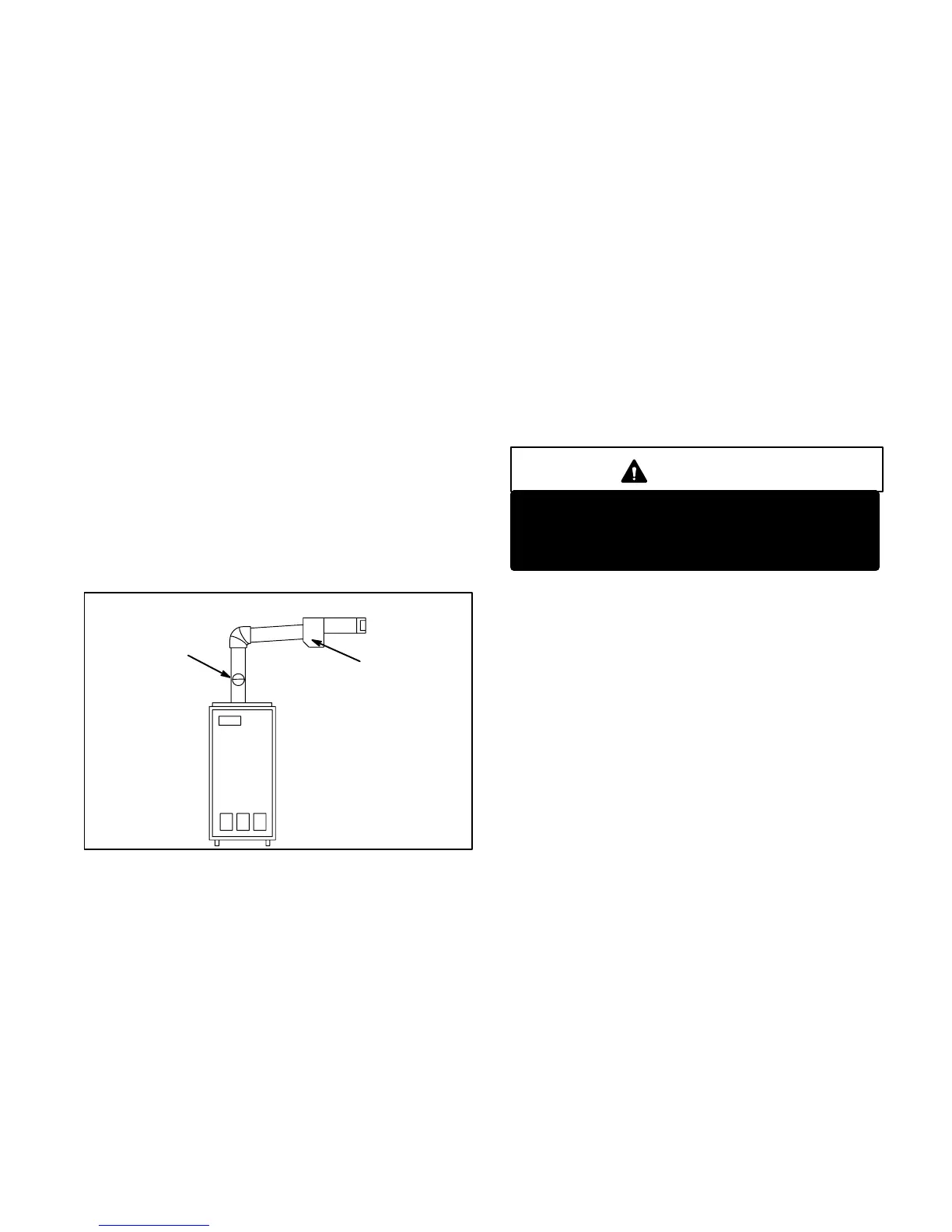

Horizontal Venting

HORIZONTAL VENTING

BAROMETRIC

CONTROL*

CONTROL FOR

HORIZONTAL

VENTING

FIGURE 24

*When using indoor air,

barometric control must be

installed in the horizontal

venting system and located

within 18" (457 mm) of vent

outlet of furnace.

When using direct connection,

barometric control must be

installed in the intake air pipe.

The O23 is approved for horizontal venting with the fol

lowing mechanical vent systems:

Tjernlund (sideshot) #SS1C and Field Controls #SWG−5 with

the CK−61 control kit. Refer to manufacturers’ installation

instructions for proper installation procedures and service

parts information.

Do not common vent with any other appliance when using

sidewall vent system.

Maximum permissible vent length is 70 equivalent feet (21.3

m). Minimum length is 15 equivalent feet (4.6 m). Each 90

elbow is equal to 6 feet (1.8 m) of straight pipe, each 45 el

bow is equal to 3 feet (0.9 m) of straight pipe. Minimum vent

pipe diameter is 4" (102 mm). Vent pipe of 5" (127 mm) and 6"

(152 mm) is permissible. Calculate the equivalent vent pipe

footage from the furnace to the mechanical vent system

(Tjernlund or Field Controls) by adding the straight vent pipe

length and the equivalent elbow lengths together.

The barometric draft control must be used in horizontal (side

wall) venting system. It must be located within 18" (457 mm) of

the furnace vent outlet. See figure 24 for barometric draft con

trol location.

III−STARTUP

A−Preliminary and Seasonal Checks

1− Inspect electrical wiring, both field and factory installed

for loose connections. Tighten as required.

2− Check line voltage. Voltage must be within range

listed on the nameplate. If not, consult the power

company and have voltage condition corrected be

fore starting unit.

B−Heating StartUp

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

Do not attempt to start the burner when excess

oil has accumulated in the chamber, when the

furnace is full of vapor or when the combus

tion chamber is very hot.

1− Set thermostat for heating demand.

2− Turn on electrical supply to unit and open all shutoff

valves in the oil supply line to the burner..

3− Check air adjustment dial on the right side of the burn

er (see figure 9). Set according to table 4.

4− On single line applications the oil pump must be

primed by bleeding the oil line. Open air bleed port and

start burner. A hose may be attached to direct oil into a

container. After last bubble is seen, bleed pump for 15

seconds. Hurried bleeding will impair efficient unit op

eration. Close port to stop bleeding. Single line instal

lations must be absolutely air tight to prevent leaks or

loss of prime.

5− If burner stops after flame is established, repeat the

bleeding procedure.

NOTE−Air bleeding is automatic on two line applica

tions; however, opening air bleed port will allow a faster

bleed. Run return line back to tank and terminate three to

four inches above the inlet line. Failure to bleed the sys

tem may cause air to be introduced into the system result

ing in a loss of prime.

6− If the burner does not start immediately, check the

safety switch on the burner primary control.

7− If burner fails to light again, refer to the trouble

shooting section in the back of this manual.

8− Proceed to section IV to complete start up.

C−Safety or Emergency Shutdown

Turn off unit power. Close all shutoff valves in the oil sup

ply line.

Loading...

Loading...