Page 23

er for a short period and then turn off. The gauge shows

cutoff pressure.

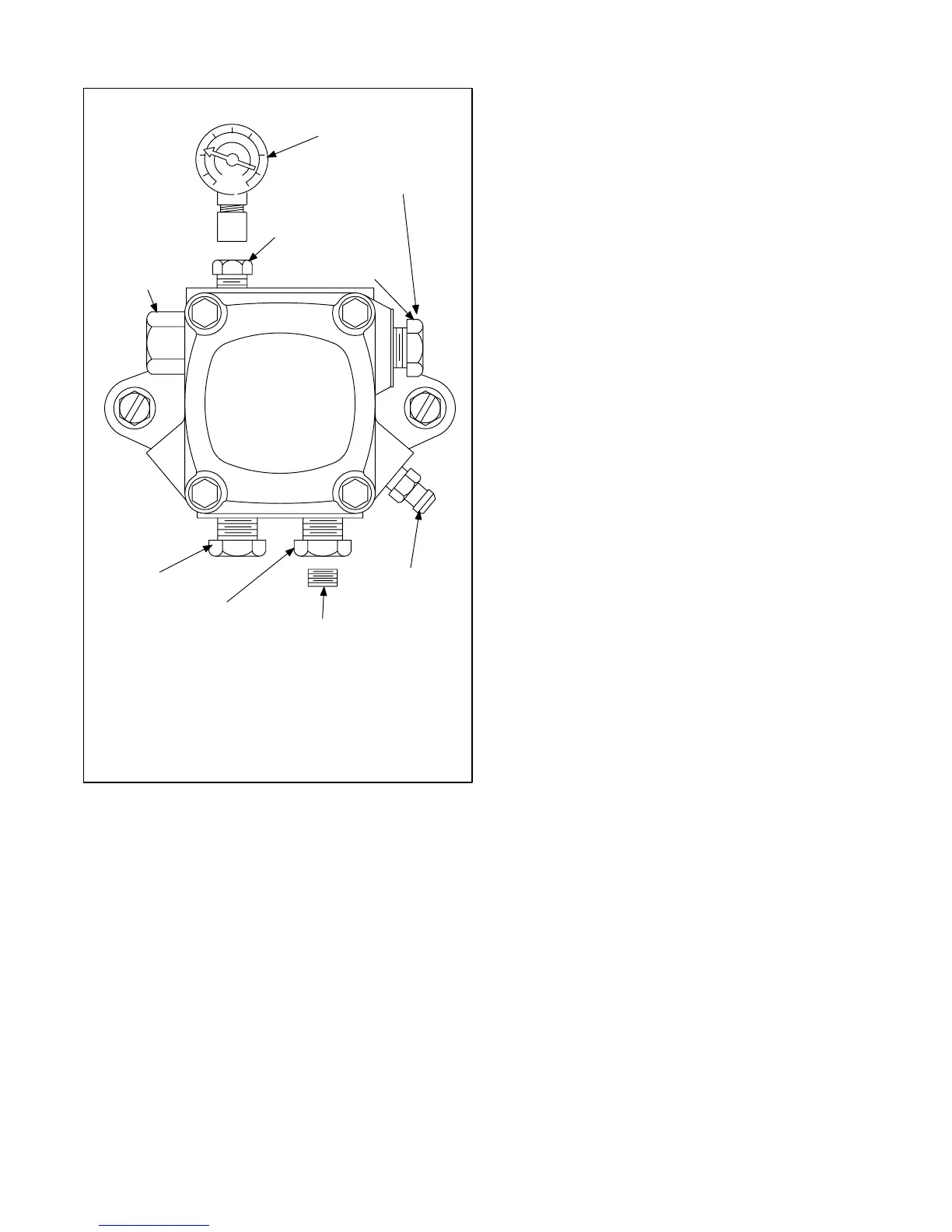

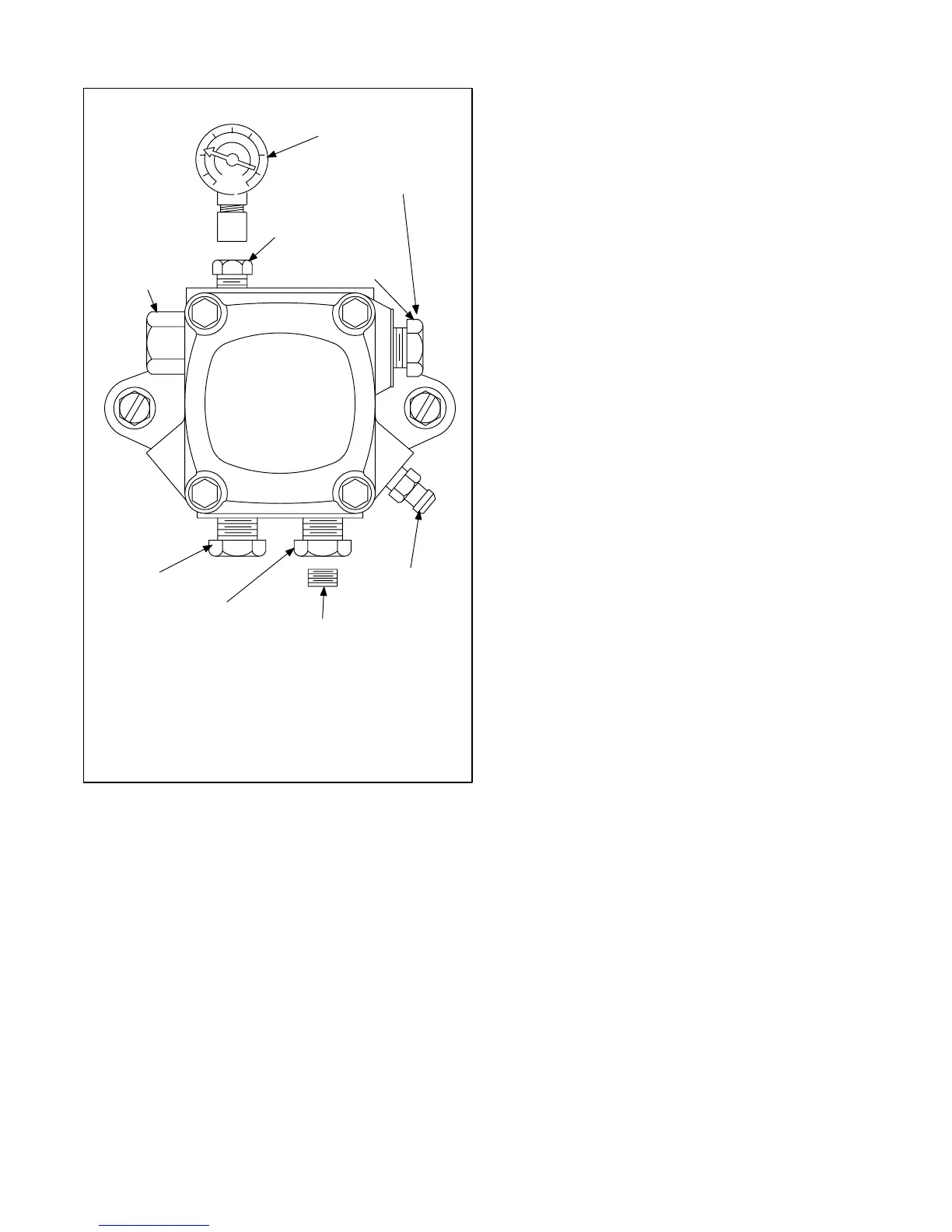

PRESSURE

GAUGE

PORT (1/8" [3mm])

INLET PORT

(1/4" [6mm])

FIGURE 28

OIL PUMP PRESSURE CHECK

RETURN PORT

(1/4" [6mm])

**TO ADJUST PRESSURE: INSERT STANDARD SCREWDRIVER.

TURN COUNTERCLOCKWISE BELOW DESIRED PRESSURE,

THEN TURN CLOCKWISE TO SET DESIRED PRESSURE.

NOZZLE PORT

(1/8" [3mm])

*PRESSURE CHECKS: NORMAL OPERATING PRESSURE IS

100 PSIG (689.5 kPa) FOR THE 023Q270 AND 140 PSIG (965.3 kPa)

FOR ALL OTHER O23, OHR23, AND OF23 UNITS. NOZZLE CUTOFF

PRESSURE IS APPROXIMATELY 80 PSIG (551.6 kPa).

BLEED PORT

1/16" (2mm) BYPASS PLUG

INSERT FOR TWOPIPE SYSTEM

(use 5/32" [4mm] allen wrench)

INLET PORT

SHOWN (1/4" [6mm])

**REGULATE PRESSURE

NOT SHOWN

(beside the inlet port)

*PRESSURE GAUGE

D−Burner Adjustment

The following instructions are essential to the proper opera

tion of O23 series oil furnaces. To prevent sooting, these in

structions must be followed in sequence:

NOTE−All w.c. measurements are below atmospheric

pressure (negative readings).

1−Draft

This test should be taken at the vent connector between

the breaching and the barometric damper. Generally a 1/4"

(6 mm) hole will need to be drilled for the draft gauge to be

inserted into the vent connector.

A minimum of 0.03" w.c. (7.5 Pa) draft must be estab

lished without the burner in operation. With the burner in

operation, the draft should be 0.04" w.c. (9.9 Pa) to 0.05"

w.c. (12.4 Pa). This is VERY critical to the flame retention

head burners.

Oil furnace installations also require careful inspection to

make sure the chimney is in good condition and can ac

commodate the products of combustion. The temperature

in unconditioned space will also affect the draft if long vent

connectors are allowed to get too cold.

2−Overfire Draft

This test should be taken with the burner in operation.

Remove the screw from the center of the center inspec

tion port. Insert your draft gauge into the hole.

A reading of the overfire draft should be 0.02" w.c. (5.0 Pa)

less than the reading found in the vent connector. If a posi

tive reading is seen at this point, the secondary heat ex

changer may be sooted or to much air may be entering

into the heat exchanger from the combustion fan. Adjust

ments to the combustion fan can be made using the air

adjustment dial.

3−Smoke Test

The smoke test should be taken at hole drilled in step 1.

Using a smoke test gun adjust the air inlet shutter so that

you will have just a trace of smoke. Somewhere be

tween a 0 and #1 smoke. This is the starting point. Do

not stop here. After the smoke test take a CO sample.

C.S.A. requires no more than 400ppm. However, a

properly installed unit under normal operating condi

tions should not read more than 50ppm.

4−CO

2

Test

Again to be taken at the vent connector pipe. With the

unit firing at a trace of smoke, test for percentage of CO

2

in the vent gas.

From the results of this test, a window of operation" will be

determined. This window of operation establishes some tol

erance. The tolerance the installer builds in provides room

within the setup for those things which might affect com

bustion. Those things which might affect combustion can

then do so without causing the unit to start sooting/smoking.

Things which might affect combustion include a nozzle go

ing bad, draft that changes during different climatic condi

tions, dirty oil, dirt obstructing the air inlet, etc.

To build in a window of operation," set up the burner to be

2% less in CO

2

. For example, if you find a reading of 12%

CO

2

, adjust the air inlet shutter to increase the air and drop

the CO

2

to 10%.

5−Retest the Smoke

With a drop in the CO

2

and increase in the air you should

see that the smoke has returned to 0.

6−Retest the Overfire Draft

This test serves to confirm that you have not increased the air

too much. Again you do not want a positive pressure at the

test port. It should still be 0.02" w.c. (5.0 kPa) less than the

draft from the vent connector. You may need to increase the

stack draft by adjusting the barometric damper.

Loading...

Loading...